china 3200mm window mesh pleating machine

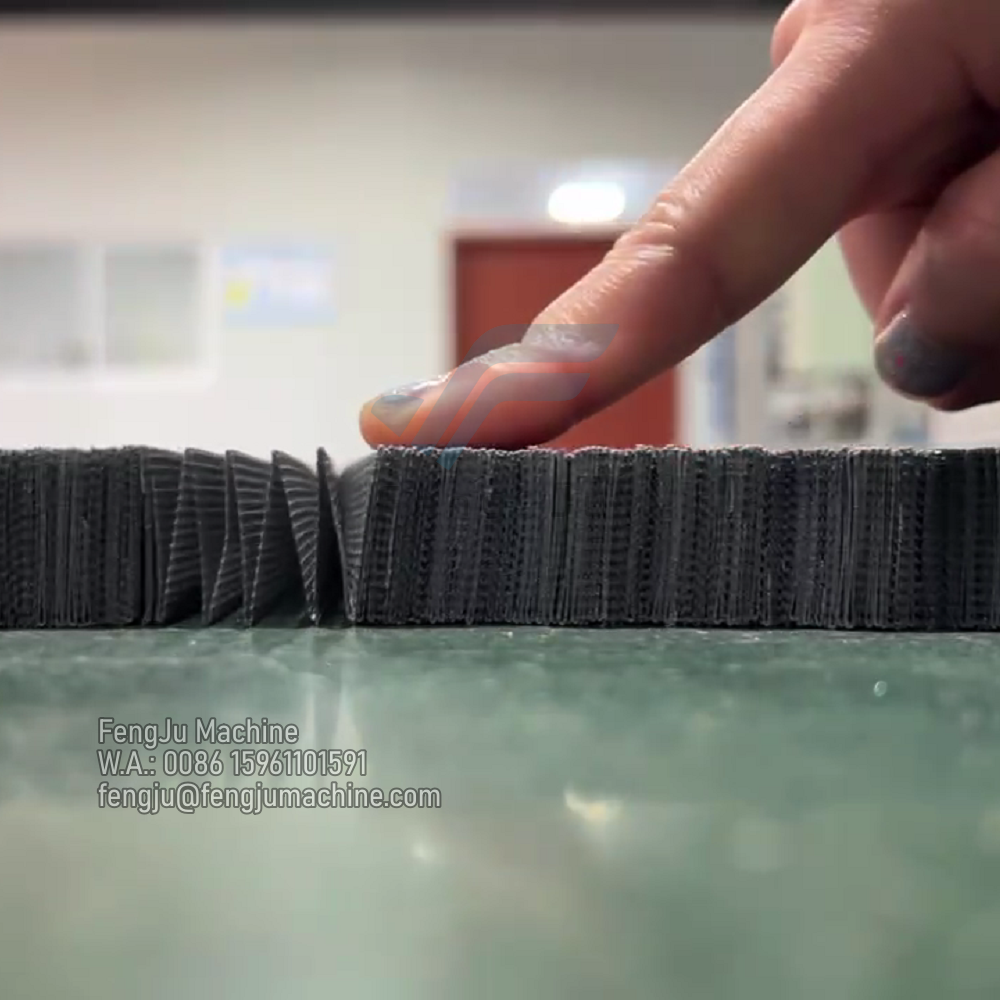

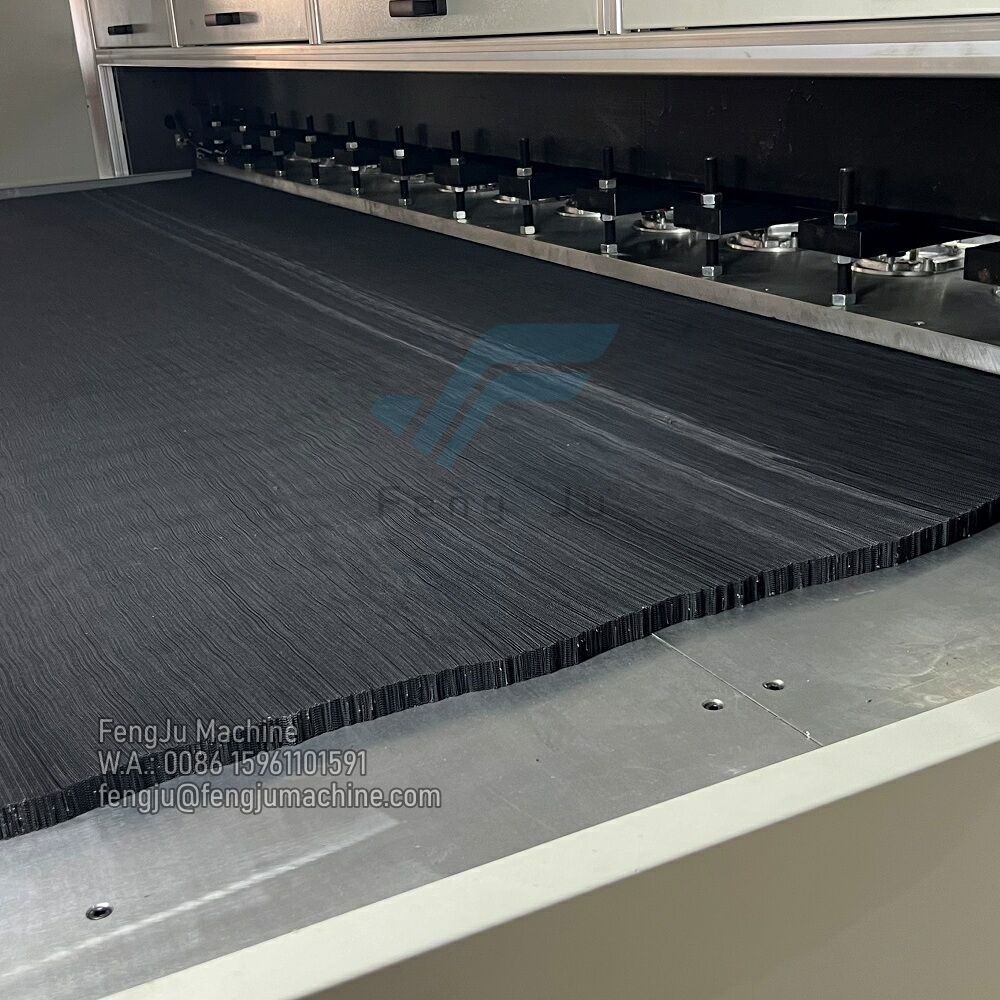

The China 3200mm Window Mesh Pleating Machine represents a cutting-edge solution in the window screening industry, designed to deliver precision and efficiency in the production of pleated mesh screens. This advanced machinery features a robust 3200mm working width, making it ideal for large-scale commercial production. The machine employs sophisticated servo motor control systems that ensure accurate pleating patterns and consistent fold depths throughout the entire width of the material. Its automated operation includes precise material feeding mechanisms, temperature-controlled pleating stations, and an advanced tension control system that prevents material distortion during the pleating process. The machine can handle various mesh materials, including fiberglass, aluminum, and polyester, with adjustable pleating depths ranging from 12mm to 25mm. The integrated PLC control system allows for easy operation and parameter adjustment, while the digital display interface provides real-time monitoring of production metrics. Notable features include automatic mesh alignment, programmable pleating patterns, and a high-efficiency cooling system that maintains optimal operating temperatures. This machine achieves production speeds of up to 12 meters per minute while maintaining exceptional pleating quality and dimensional stability.