3000mm fly screen pleating machine factory

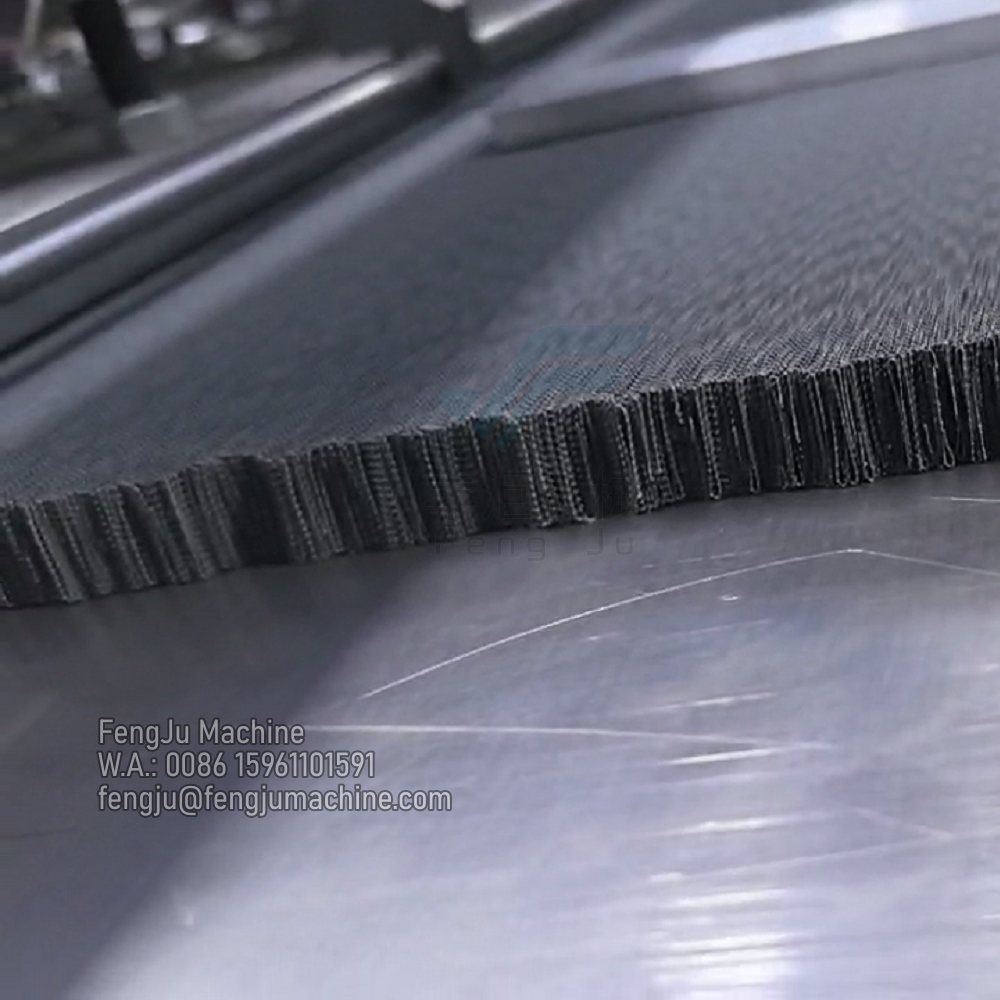

The 3000mm fly screen pleating machine factory represents a cutting-edge manufacturing facility dedicated to producing high-precision pleating equipment for the window screening industry. This state-of-the-art facility specializes in the production of machines capable of handling wide-format materials up to 3000mm, making it ideal for commercial and industrial applications. The factory incorporates advanced automation systems and quality control measures throughout the production process, ensuring consistent output and superior product quality. The facility's production line is equipped with precision engineering capabilities, including computer-controlled assembly stations, automated testing systems, and rigorous quality inspection protocols. The machines produced here feature innovative pleating mechanisms that create uniform, durable pleats in window screening materials, with adjustable pleat depths and spacing options to meet various customer specifications. The factory's technical capabilities extend to customization services, allowing for modifications to meet specific client requirements. Additionally, the facility maintains a dedicated research and development department focused on continuous improvement and innovation in pleating technology. With its comprehensive approach to manufacturing excellence, the factory has established itself as a leading provider of industrial-grade pleating solutions for the global market.