china pleated flyscreen machine

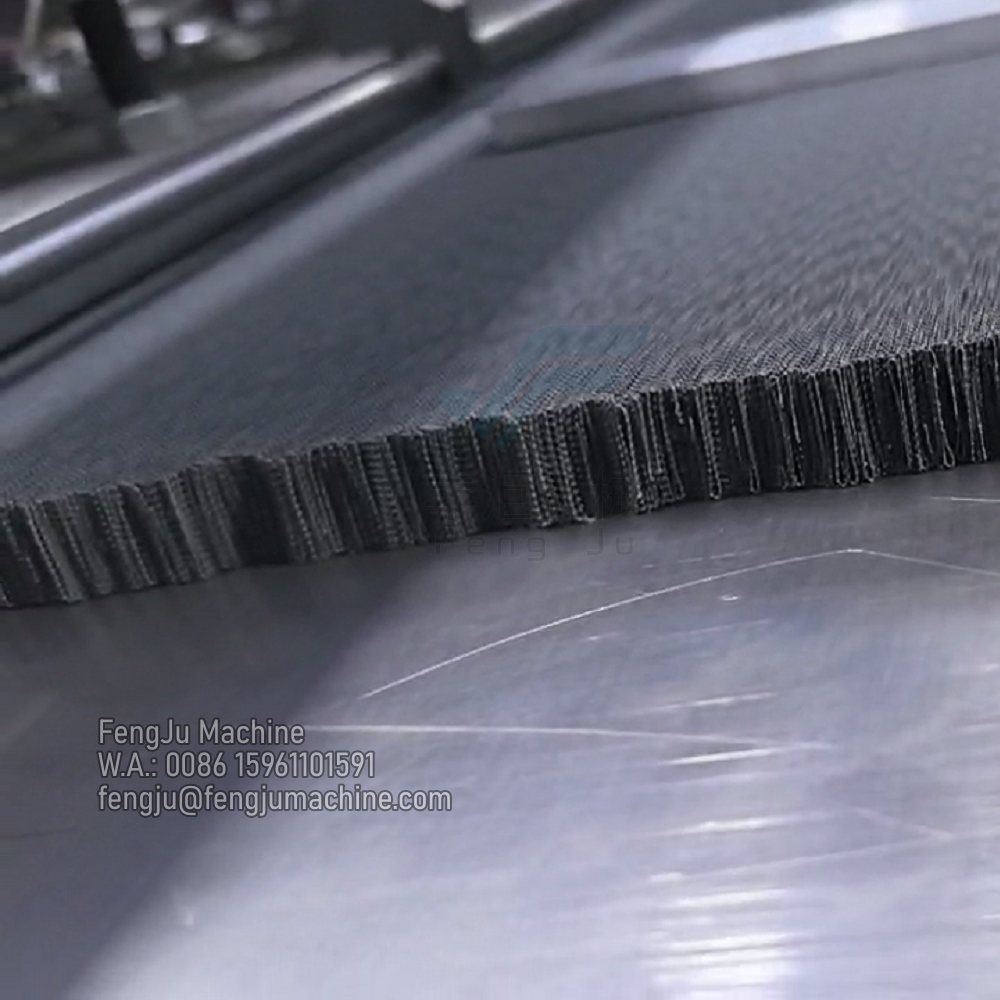

The China pleated flyscreen machine represents a cutting-edge solution in the manufacturing of pleated insect screens. This advanced equipment combines precision engineering with automated functionality to produce high-quality pleated mesh screens efficiently and consistently. The machine features a sophisticated pleating system that creates uniform, durable folds in the mesh material, ensuring optimal functionality and aesthetic appeal. Its computerized control system allows operators to adjust pleating specifications, including width, depth, and spacing, to meet diverse customer requirements. The machine incorporates multiple stations for material feeding, pleating, cutting, and finishing, streamlining the entire production process. With its robust construction and precision components, it can handle various mesh materials, from traditional fiberglass to innovative synthetic options. The automated tension control system ensures consistent pleating quality, while the integrated quality control mechanisms detect and prevent potential defects. This machine significantly reduces production time and labor costs while maintaining superior product quality. Its modular design facilitates easy maintenance and upgrades, making it a long-term investment for screen manufacturing facilities. The equipment's versatility allows for the production of both standard and custom-sized pleated screens, catering to residential and commercial applications.