pleated flyscreen machine manufacturer

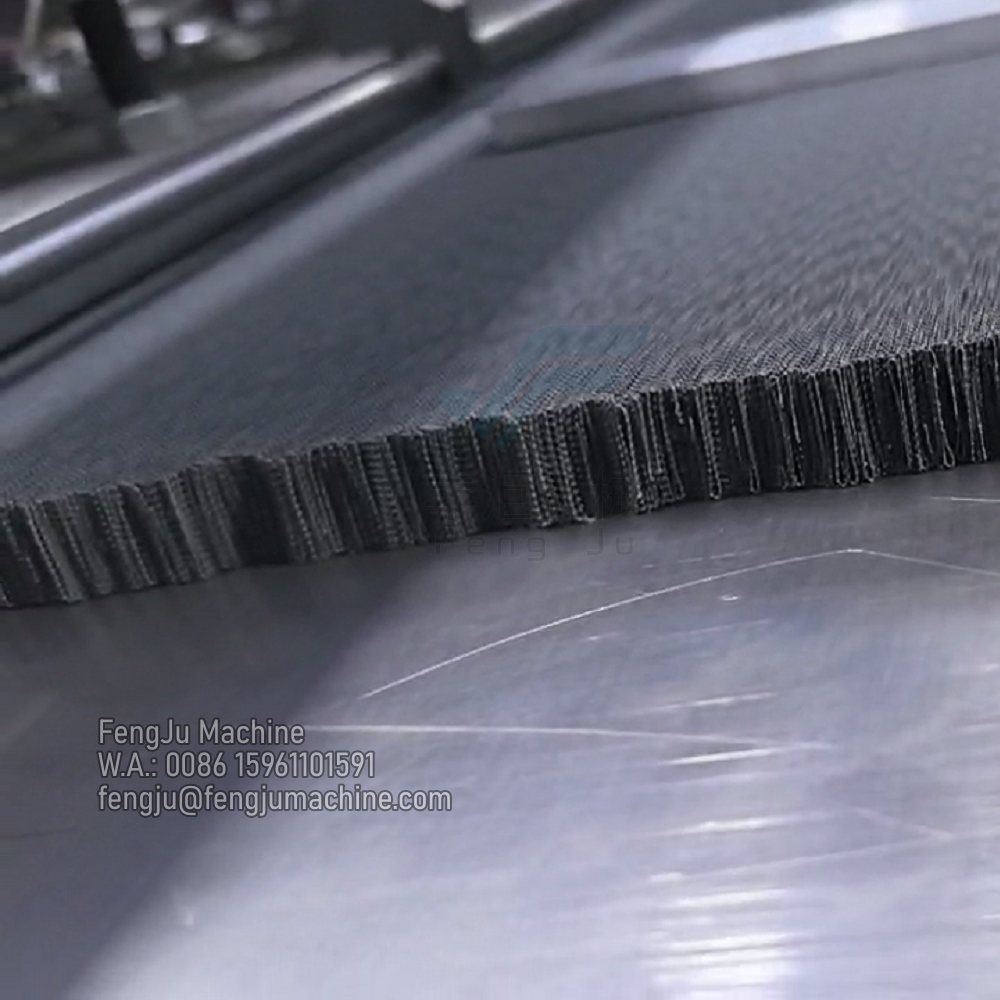

A pleated flyscreen machine manufacturer stands at the forefront of innovative insect protection solutions, specializing in the production of sophisticated equipment that creates precise and durable pleated mesh screens. These advanced machines incorporate cutting-edge technology to produce screens that combine functionality with aesthetic appeal. The manufacturing process involves state-of-the-art pleating systems that ensure consistent fold patterns, automated cutting mechanisms for precise measurements, and quality control systems that maintain product excellence. The machines are designed to handle various mesh materials, including fiberglass, aluminum, and polyester, offering versatility in production capabilities. They feature computerized control systems that enable precise adjustments for different pleating specifications, ensuring optimal screen performance and longevity. The manufacturer's equipment includes integrated testing stations to verify the durability and smooth operation of the finished products. These machines are capable of producing screens suitable for various applications, from residential windows and doors to commercial installations, with customizable width and height options to meet diverse market demands.