3000mm fly screen pleating machine

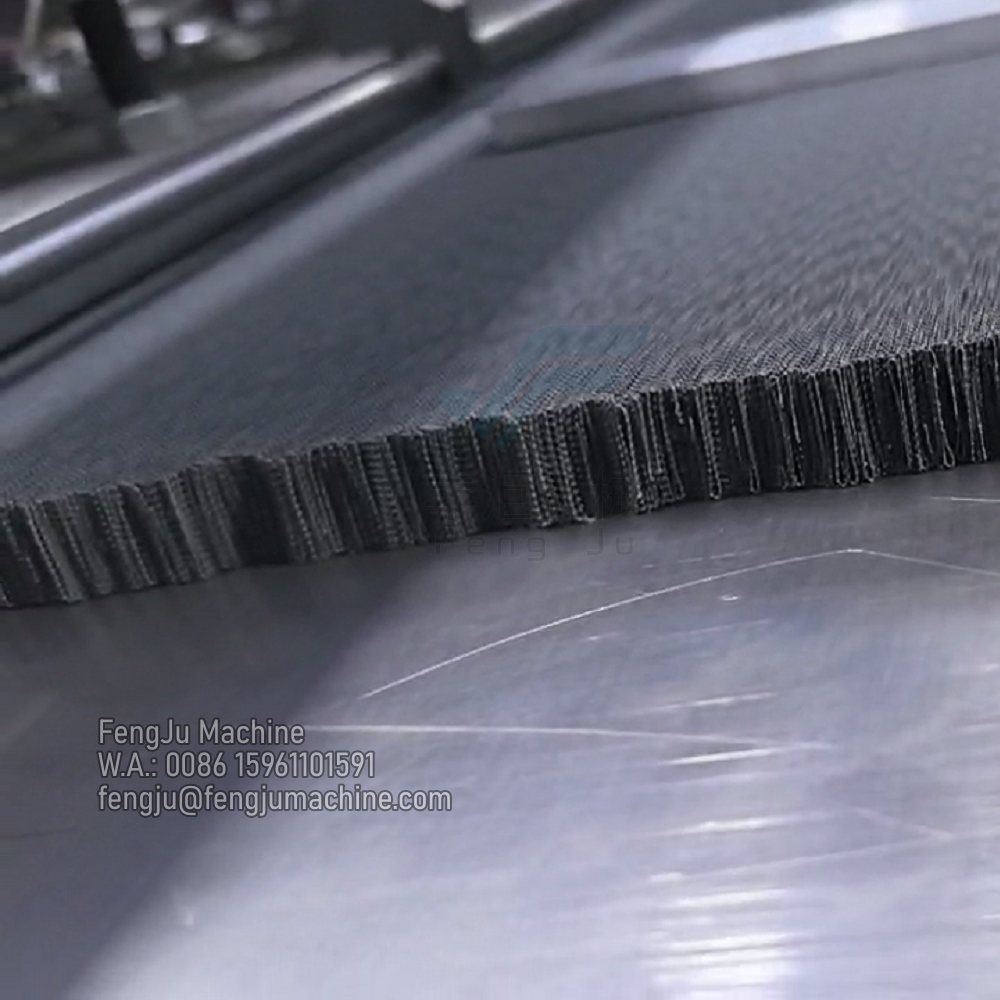

The 3000mm fly screen pleating machine represents a significant advancement in window screen manufacturing technology. This state-of-the-art equipment specializes in the precise pleating of mesh materials up to 3000mm in width, making it ideal for large-scale industrial applications. The machine features an advanced servo motor control system that ensures consistent pleating accuracy and maintains uniform fold patterns throughout the production process. Its robust construction incorporates high-grade stainless steel components, guaranteeing durability and long-term reliability. The automated feeding mechanism streamlines the production workflow, while the digital control panel allows operators to easily adjust pleating parameters, including depth, angle, and speed. The machine's innovative tension control system prevents material distortion and ensures the highest quality output. With a production speed of up to 40 meters per minute, it significantly enhances manufacturing efficiency while maintaining precise pleating standards. The integrated safety features, including emergency stop buttons and protective guards, ensure operator safety without compromising accessibility for maintenance and material loading. The machine also includes a sophisticated counting system for accurate production tracking and quality control purposes.