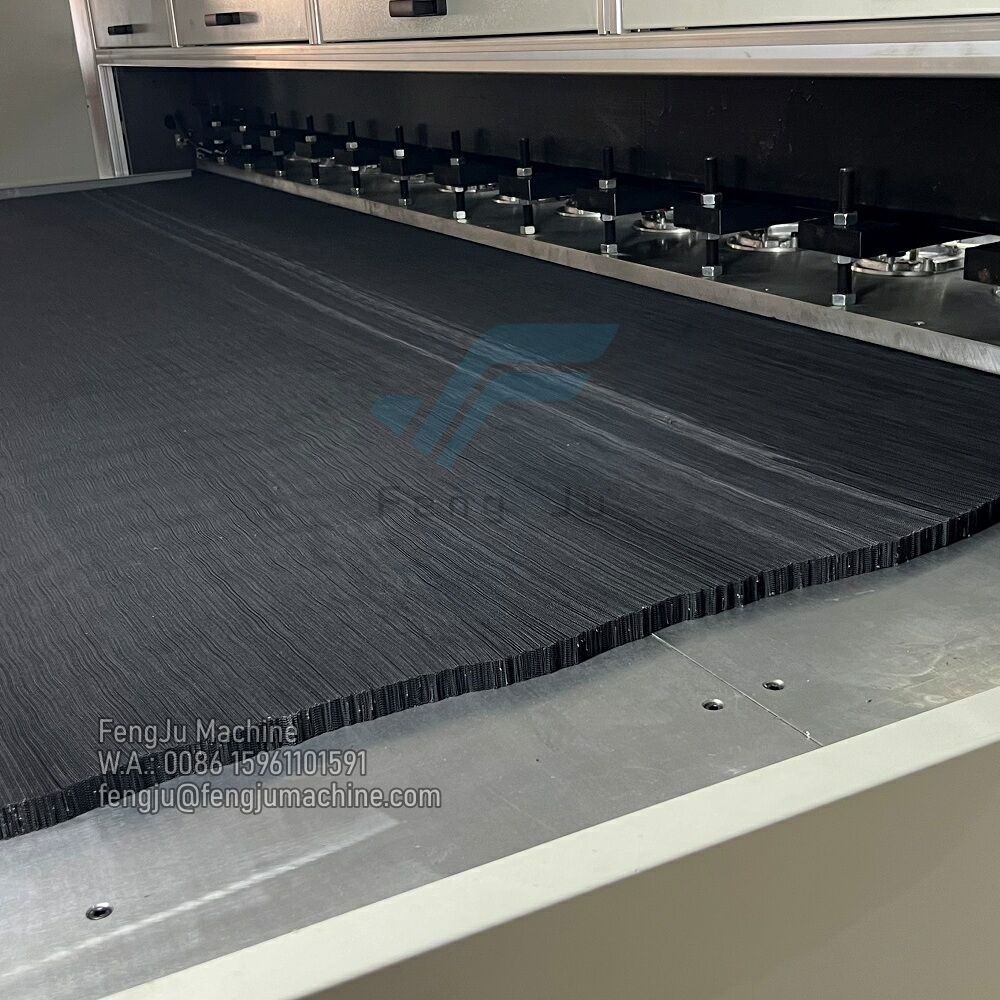

windowmesh pleating machine factory

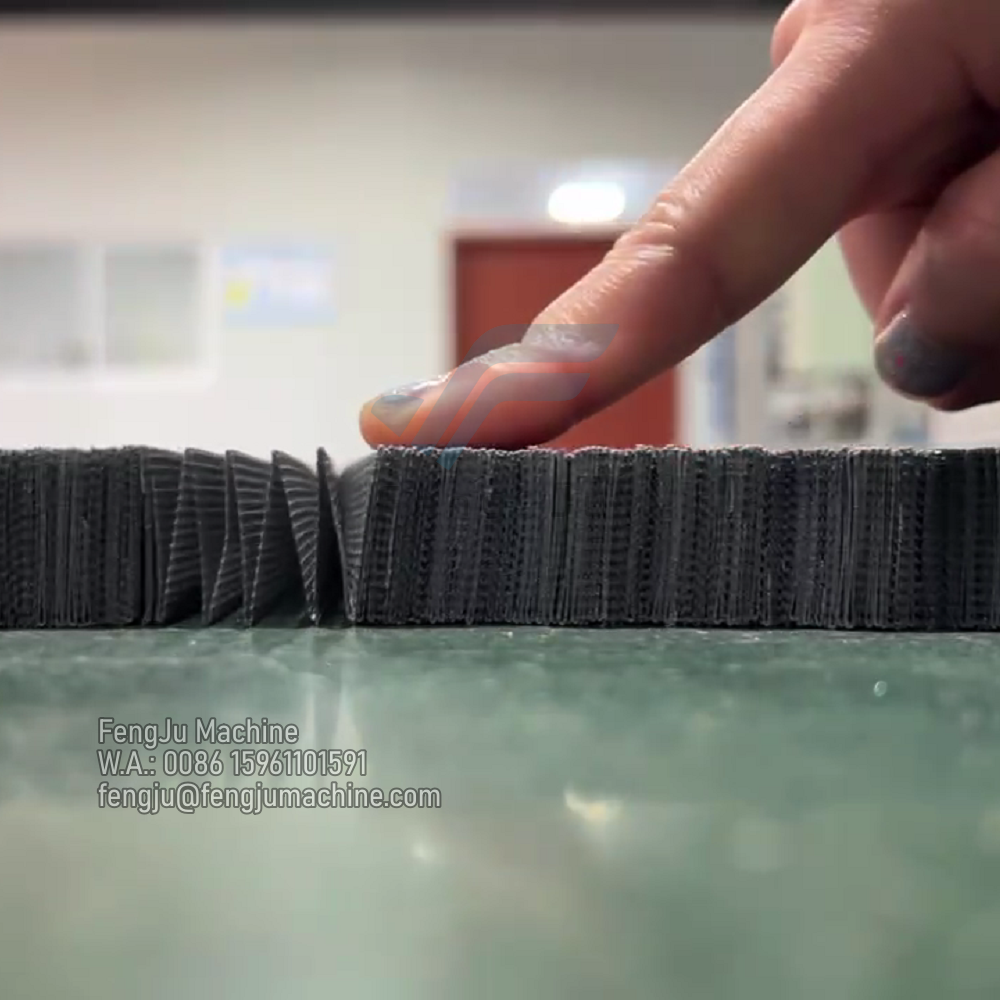

A windowmesh pleating machine factory represents a cutting-edge manufacturing facility dedicated to producing high-precision equipment for the window screening industry. These specialized facilities incorporate advanced automation systems and precision engineering to create machines that efficiently fold and pleat window mesh materials. The factory's production line utilizes state-of-the-art CNC technology and robust quality control measures to ensure consistent output quality. The facility's core capabilities include manufacturing machines that can handle various mesh materials, from standard fiberglass to specialized metal meshes, with adjustable pleating patterns and sizes. The production setup features multiple assembly stations equipped with modern calibration tools and testing equipment to verify the accuracy of each machine's pleating mechanisms. Environmental controls maintain optimal conditions for assembly and testing, while integrated software systems monitor production metrics and machine performance. The factory's research and development department continuously works on improving pleating precision, speed, and energy efficiency. With a focus on sustainability, the facility implements eco-friendly manufacturing practices and waste reduction protocols. The factory also maintains a comprehensive spare parts inventory and provides technical support services to ensure customer satisfaction and machine longevity.