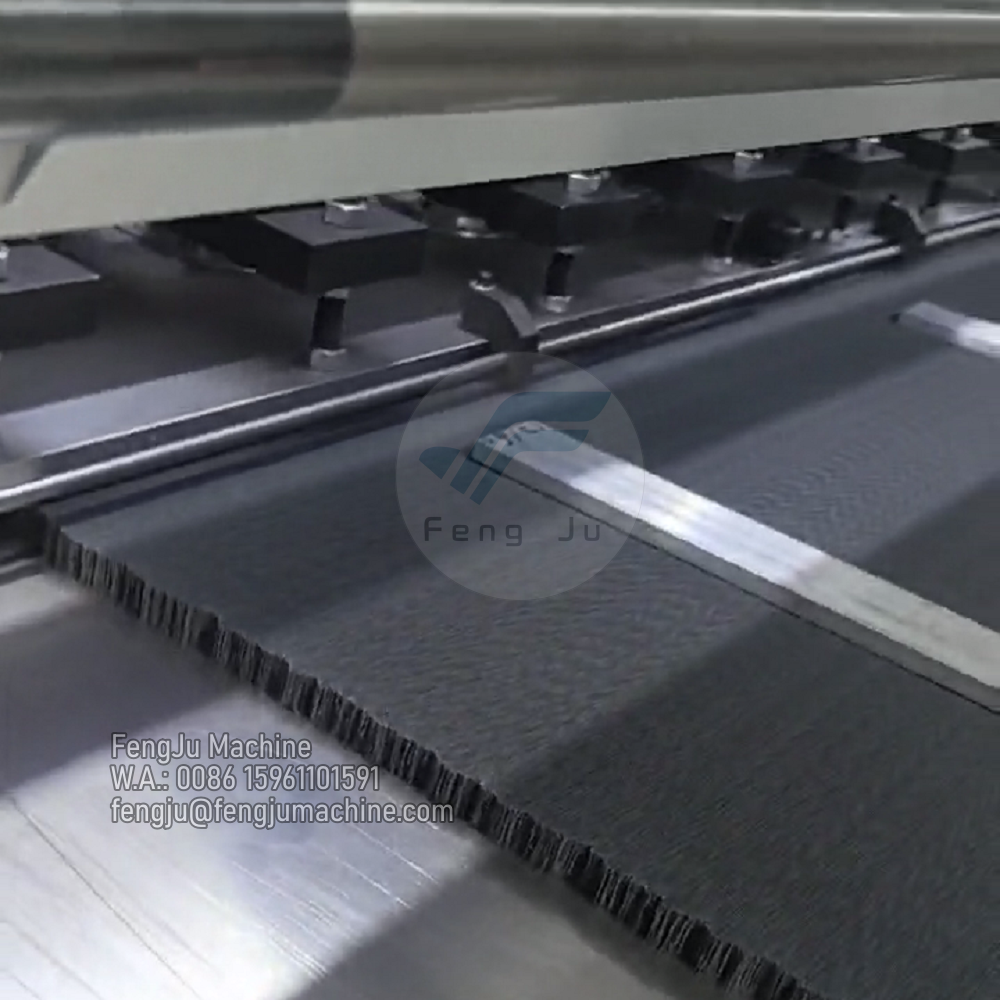

polyester pleating machine

The polyester pleating machine is an advanced textile processing equipment designed specifically for creating precise, uniform pleats in polyester fabrics. This sophisticated machinery employs a combination of heat setting and mechanical folding mechanisms to produce consistent, durable pleats that maintain their shape even after multiple washes. The machine operates through a systematic process where fabric is fed through heated plates that are precisely calibrated to the optimal temperature for polyester processing, typically between 180-200 degrees Celsius. The equipment features adjustable pleat depth settings, allowing for various pleat sizes ranging from micro-pleats to larger box pleats. Its automated feeding system ensures consistent fabric tension throughout the pleating process, while the digital control panel enables operators to monitor and adjust parameters such as temperature, speed, and pressure in real-time. The machine's applications extend across multiple industries, from fashion and garment manufacturing to industrial textile production, making it an essential tool for businesses requiring high-volume pleated fabric production. Modern polyester pleating machines are equipped with safety features including emergency stop mechanisms and temperature control systems to prevent fabric damage and ensure operator safety.