pleating paper machine

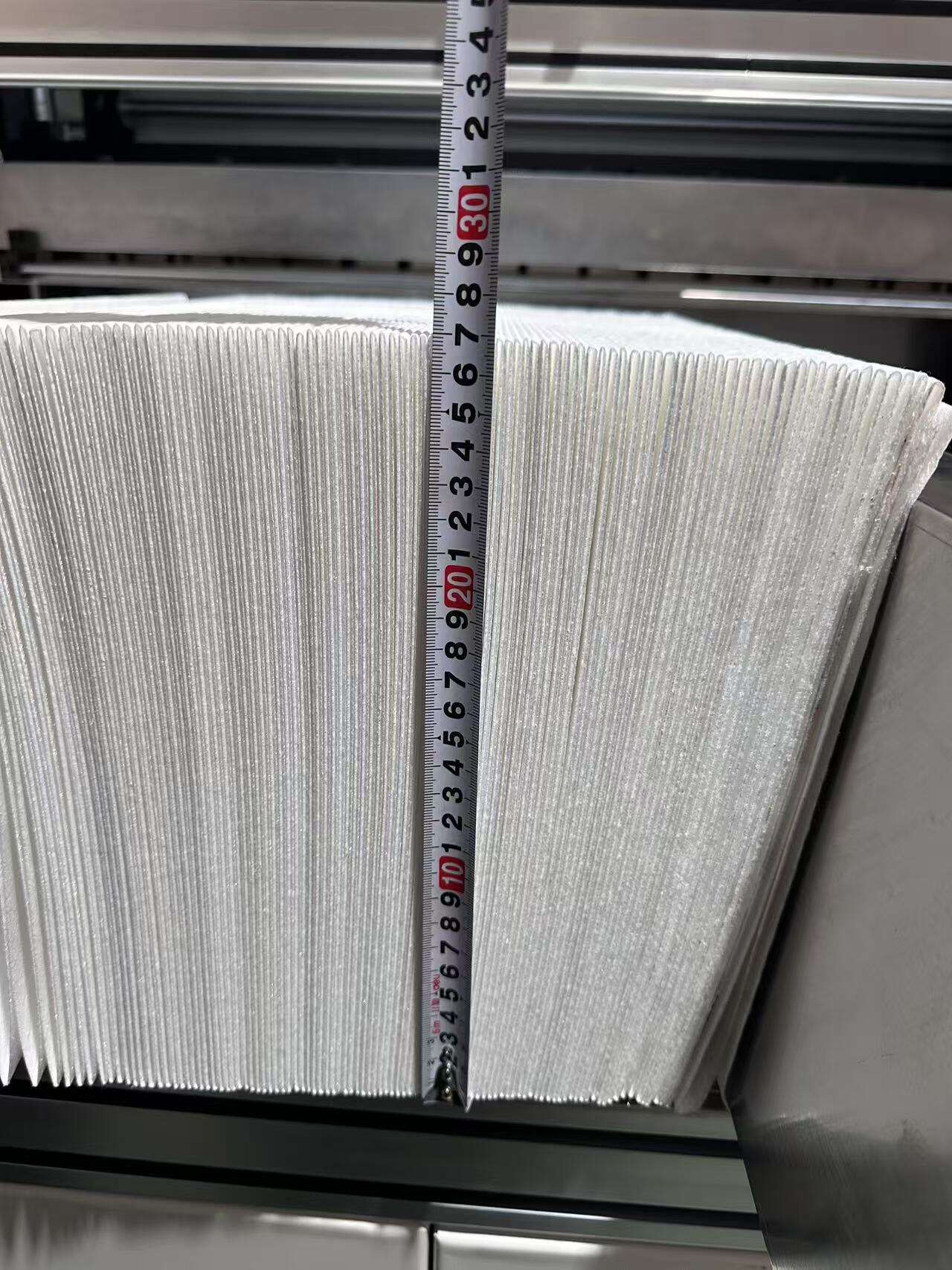

The pleating paper machine represents a sophisticated piece of manufacturing equipment designed to create precise and uniform pleats in various types of paper materials. This advanced machinery combines mechanical precision with automated control systems to produce consistently high-quality pleated paper products. The machine's core functionality includes feed roller mechanisms that precisely control paper input, specialized pleating units that form uniform folds, and heating elements that help set and stabilize the pleats. The technology incorporates adjustable settings for pleat depth, spacing, and pattern variations, allowing manufacturers to create products that meet diverse specifications. Applications of the pleating paper machine span multiple industries, from filtration system manufacturing to decorative paper products. The machine excels in producing pleated materials for air filters, automotive filters, and industrial separation systems, while also serving the packaging and craft industries. Modern pleating paper machines feature digital control interfaces, automated tension control, and precise temperature regulation systems that ensure consistent output quality. The equipment's versatility allows for processing different paper weights and types, making it invaluable for manufacturers requiring flexible production capabilities.