rotary filter paper pleating machine

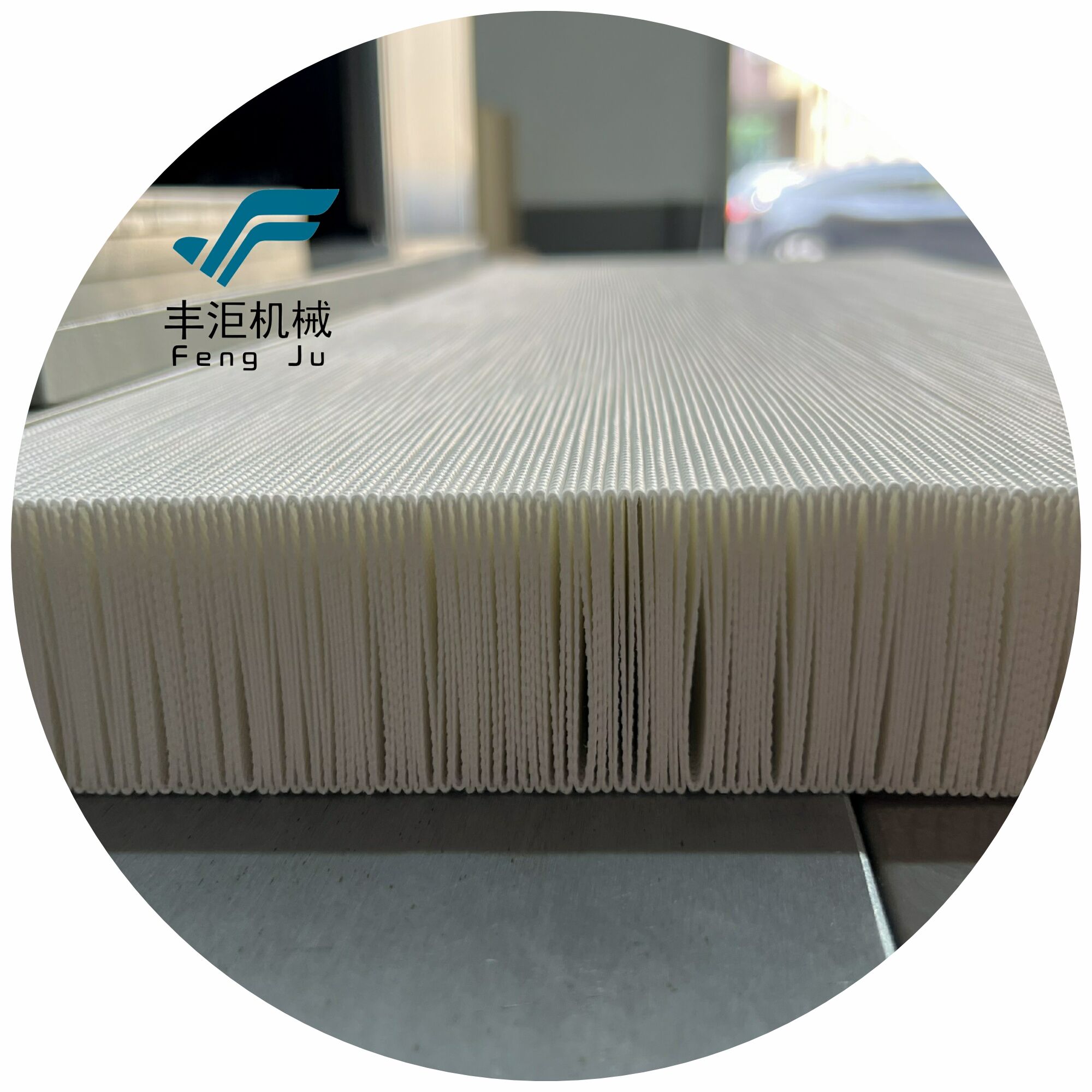

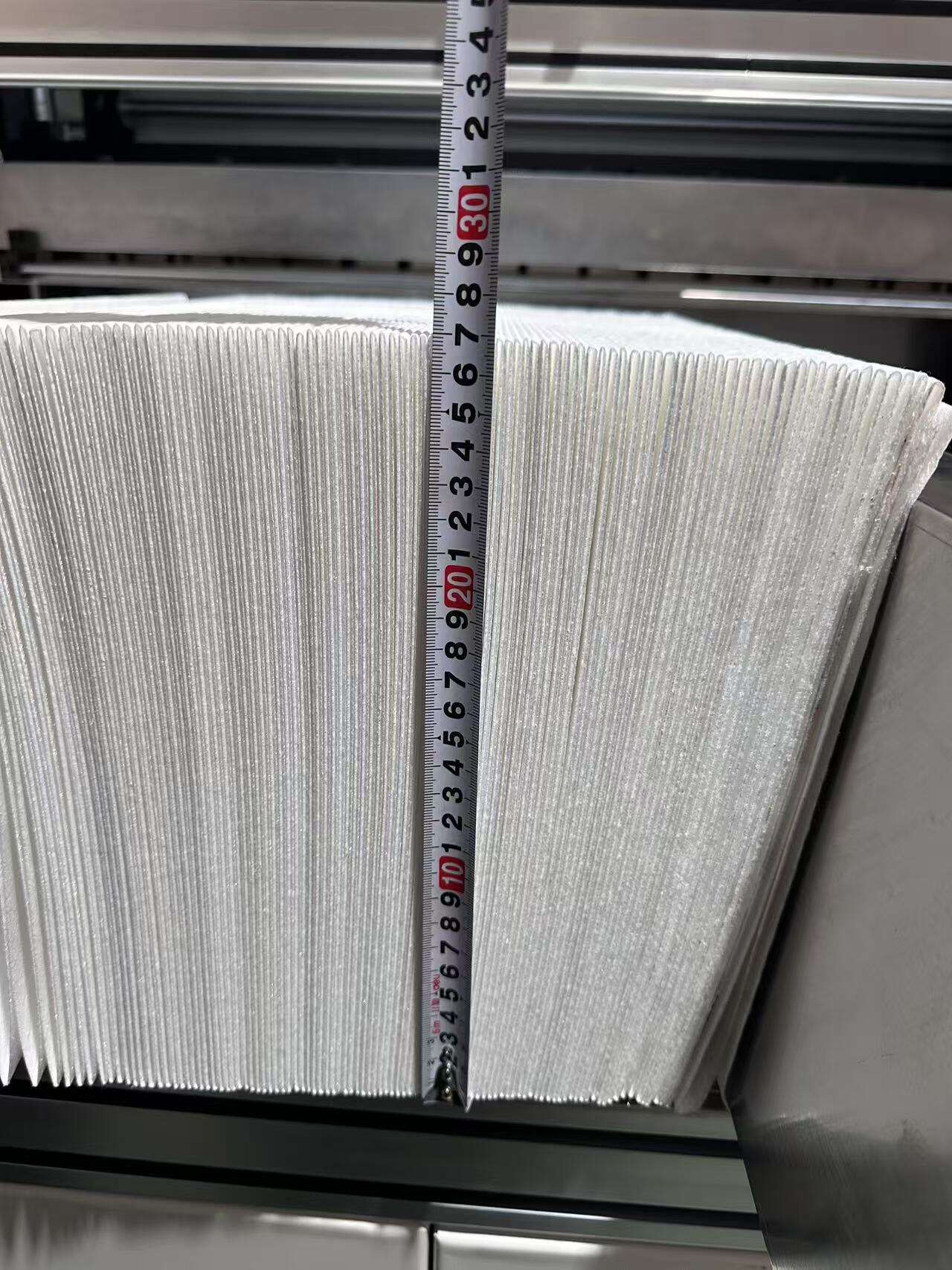

The rotary filter paper pleating machine represents a cutting-edge solution in the filtration industry, designed to create precise pleats in filter media with exceptional consistency and efficiency. This sophisticated equipment operates through a continuous rotary motion system that carefully handles and processes filter paper material. The machine integrates advanced servo motor controls with precision pleat depth adjustment mechanisms, ensuring uniform pleat formation throughout the entire production cycle. At its core, the machine features a rotating pleating drum equipped with specialized scoring blades that create precise fold lines in the filter media. The technology incorporates automatic tension control systems that maintain optimal material feed rates, while sophisticated sensors monitor and adjust pleating parameters in real time. This machine is capable of processing various filter media types, including cellulose, synthetic, and composite materials, with pleat heights ranging from 20mm to 100mm. Applications span across automotive, HVAC, industrial air filtration, and liquid filtration systems, making it an essential tool for filter manufacturers seeking high-quality pleated products. The machine's modular design allows for quick material changeovers and maintenance, while its digital control interface enables operators to store and recall specific pleating parameters for different product specifications.