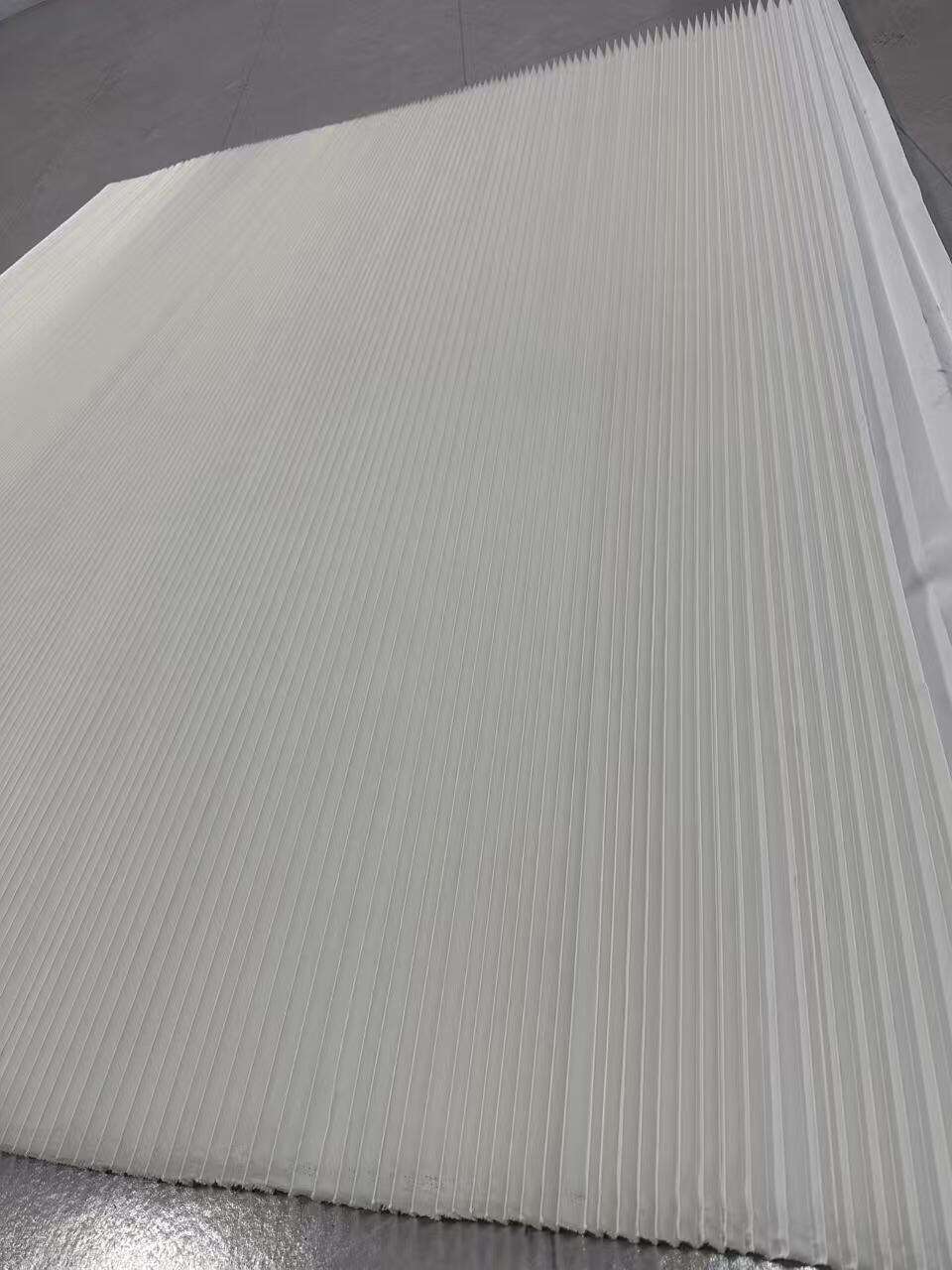

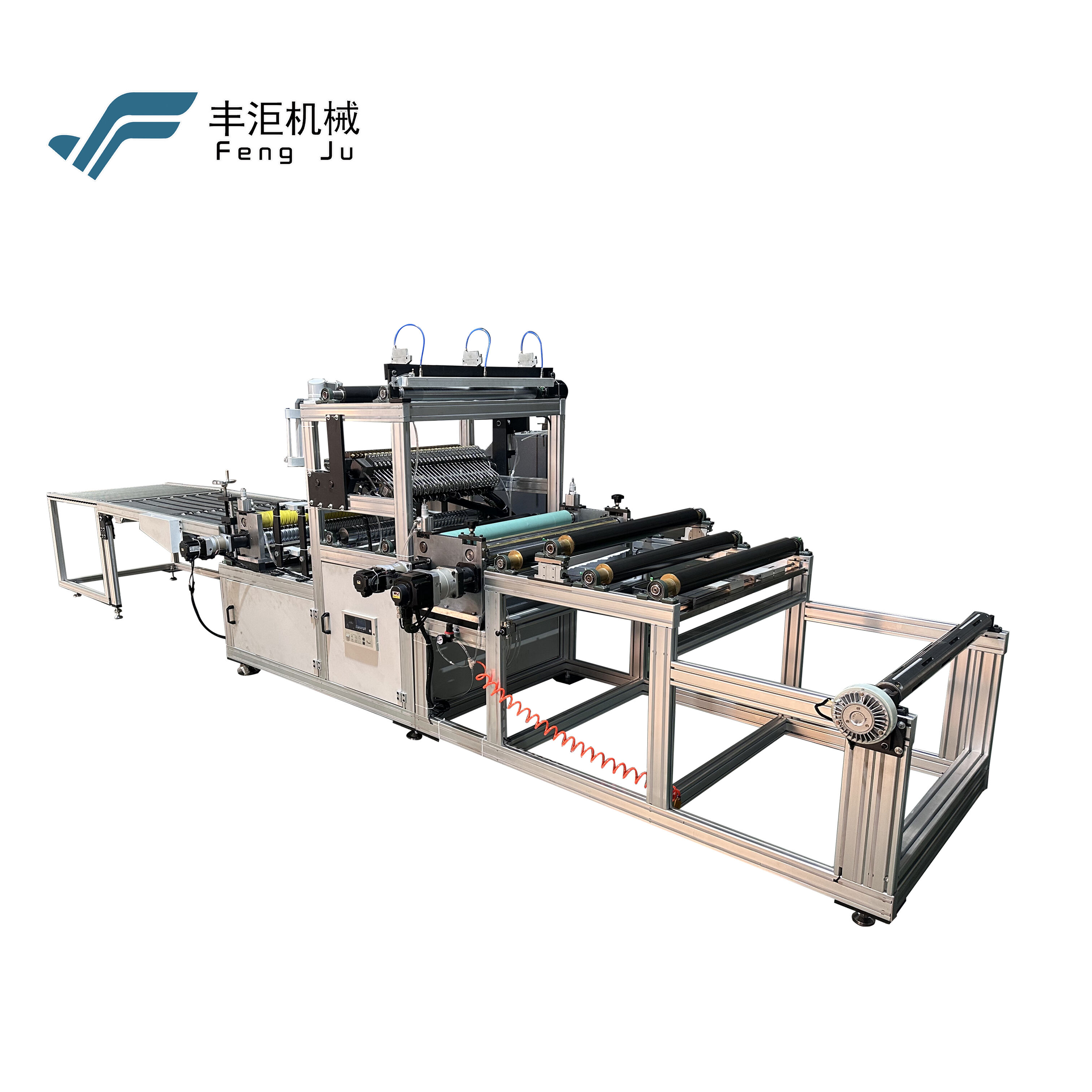

pleating machine folding

A pleating machine folding system represents a sophisticated piece of industrial equipment designed to create precise, uniform pleats in various fabric materials. This advanced machinery combines mechanical precision with automated controls to achieve consistent folding patterns across different textile types. The system typically incorporates adjustable plate settings, temperature controls, and precise timing mechanisms to ensure optimal pleat formation. The machine operates by feeding fabric through specially designed plates that create permanent creases through a combination of heat, pressure, and mechanical movement. Its main functions include continuous pleating for large-scale production, pattern memory capabilities for different pleat styles, and automatic fabric feeding mechanisms. The technology features advanced sensors that monitor pleat depth, spacing, and overall quality, while maintaining consistent temperature distribution throughout the pleating process. These machines are particularly valuable in textile manufacturing, fashion production, and industrial fabric processing. They can handle various fabric weights and compositions, from lightweight synthetics to heavier natural fibers, making them versatile tools in modern textile production. Applications extend beyond traditional clothing manufacturing to include automotive textiles, industrial filters, and specialized technical fabrics. The system's precision ensures repeatability in pleat patterns, essential for maintaining product consistency in mass production environments.