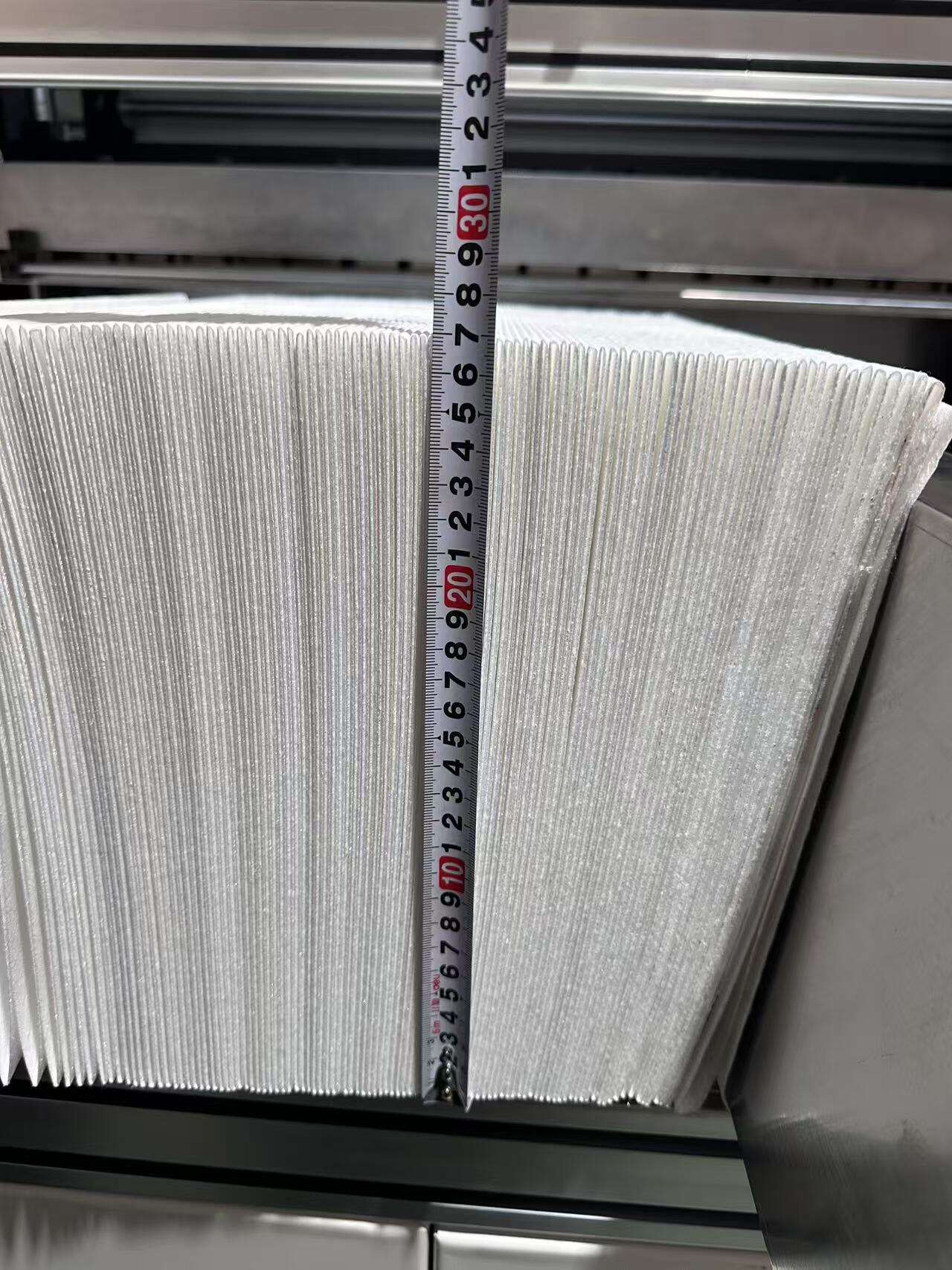

air filter paper pleated machine

The air filter paper pleated machine represents a cutting-edge solution in filtration technology manufacturing. This sophisticated equipment automates the precise folding of filter media into uniform pleats, ensuring consistent quality and optimal filtration performance. The machine incorporates advanced servo motor systems that control pleat depth, height, and spacing with exceptional accuracy, while its high-speed operation capability enables efficient production rates of up to 50 meters per minute. The system features an intelligent tension control mechanism that prevents material distortion and maintains structural integrity throughout the pleating process. Its versatile design accommodates various filter media thicknesses, ranging from 0.2mm to 2.0mm, making it suitable for producing both fine particle and coarse filtration elements. The machine includes automated scoring wheels that create precise fold lines, ensuring sharp and uniform pleats that maximize the filtration surface area. Additionally, it incorporates real-time monitoring systems that track production parameters and automatically adjust settings to maintain consistent pleat geometry. This technology is essential in manufacturing air filters for HVAC systems, automotive applications, industrial air purification, and clean room environments.