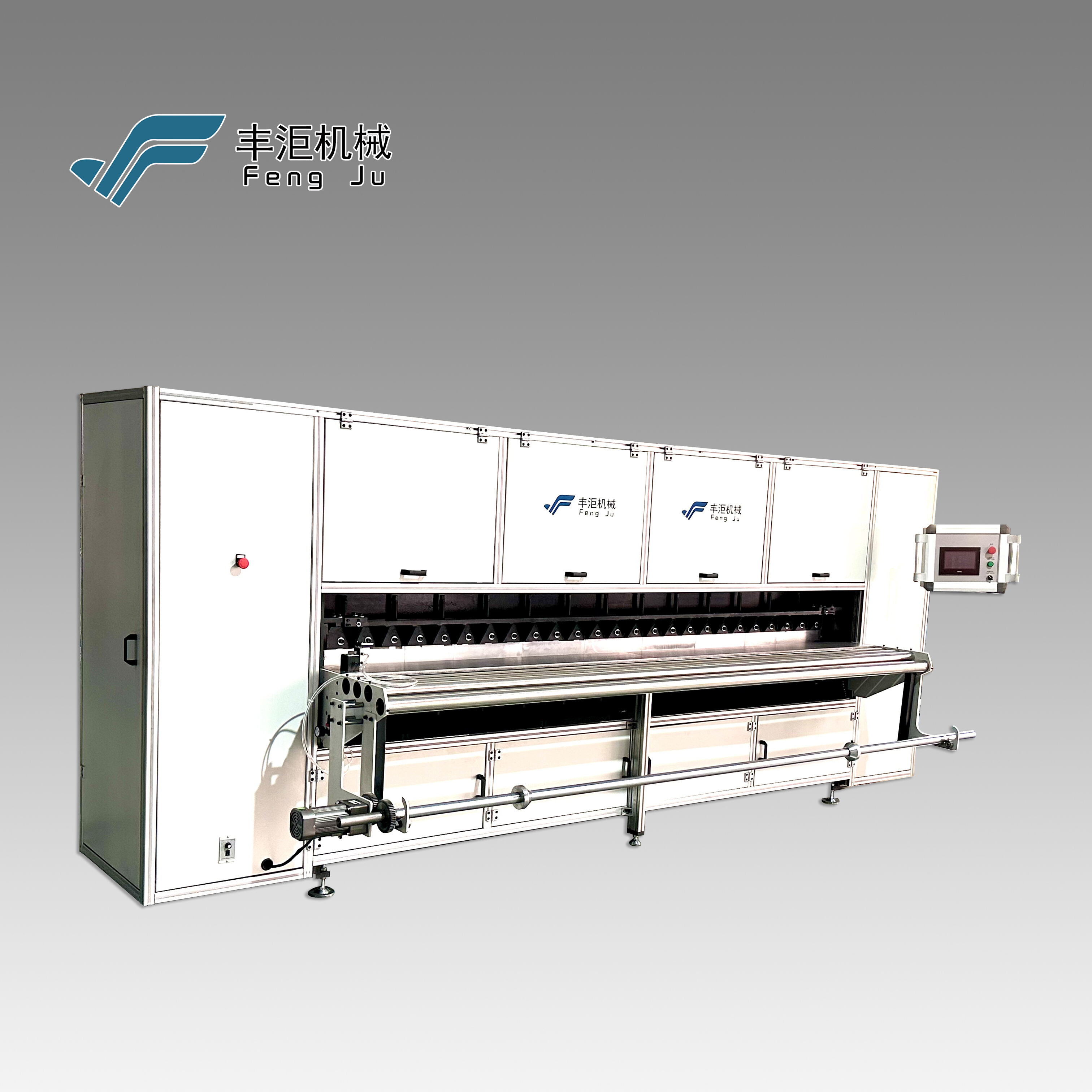

pleated filter folding machine

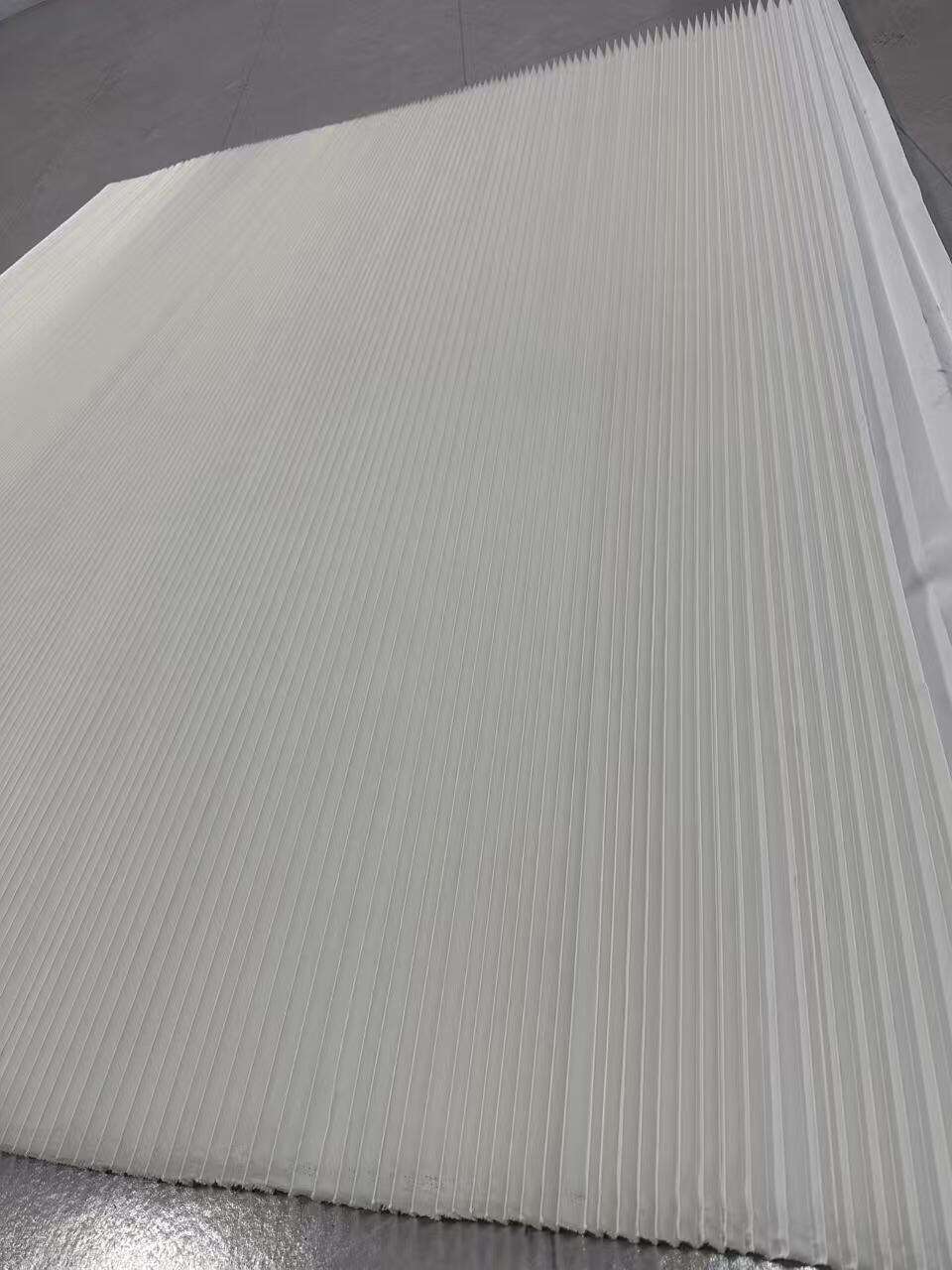

The pleated filter folding machine represents a cutting-edge solution in filter manufacturing technology, designed to create precise and uniform pleated filter elements with exceptional efficiency. This sophisticated equipment automates the intricate process of folding filter media into consistent pleats, ensuring optimal filtration performance across various applications. The machine incorporates advanced scoring and folding mechanisms that carefully manipulate filter materials, maintaining structural integrity while achieving precise pleat geometries. It features adjustable pleat depth and spacing controls, allowing manufacturers to customize filter specifications according to specific requirements. The machine's automated feed system handles various filter media types, from synthetic materials to fiberglass, while maintaining consistent tension throughout the pleating process. Its integrated quality control systems continuously monitor pleat formation, ensuring uniformity and reducing material waste. The technology includes sophisticated temperature control systems for processing heat-sensitive materials and can accommodate different filter widths and lengths. With production speeds capable of meeting high-volume manufacturing demands, the machine maintains precise pleat counts and depths while minimizing human intervention in the production process.