petrol filter pleating machine

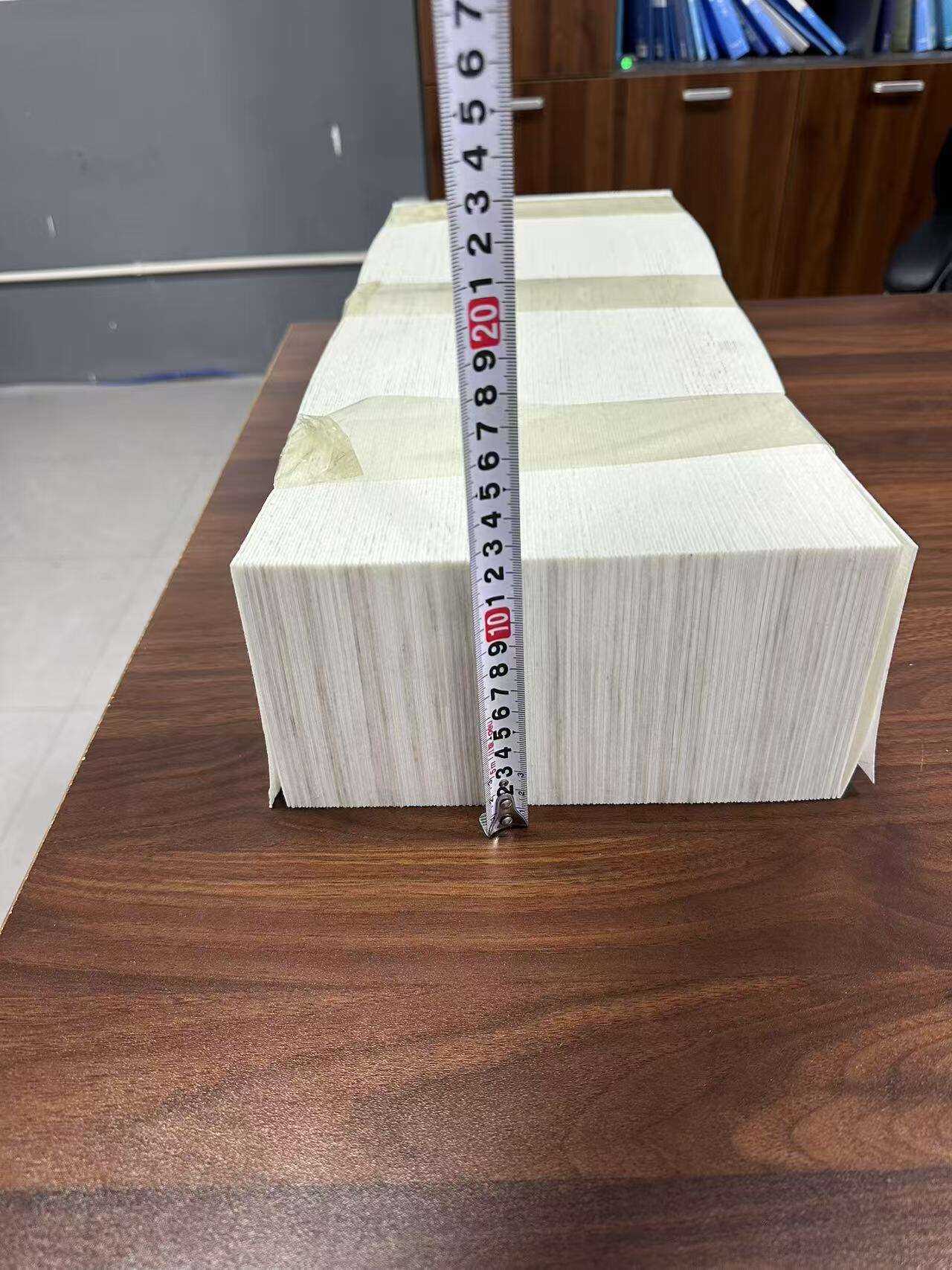

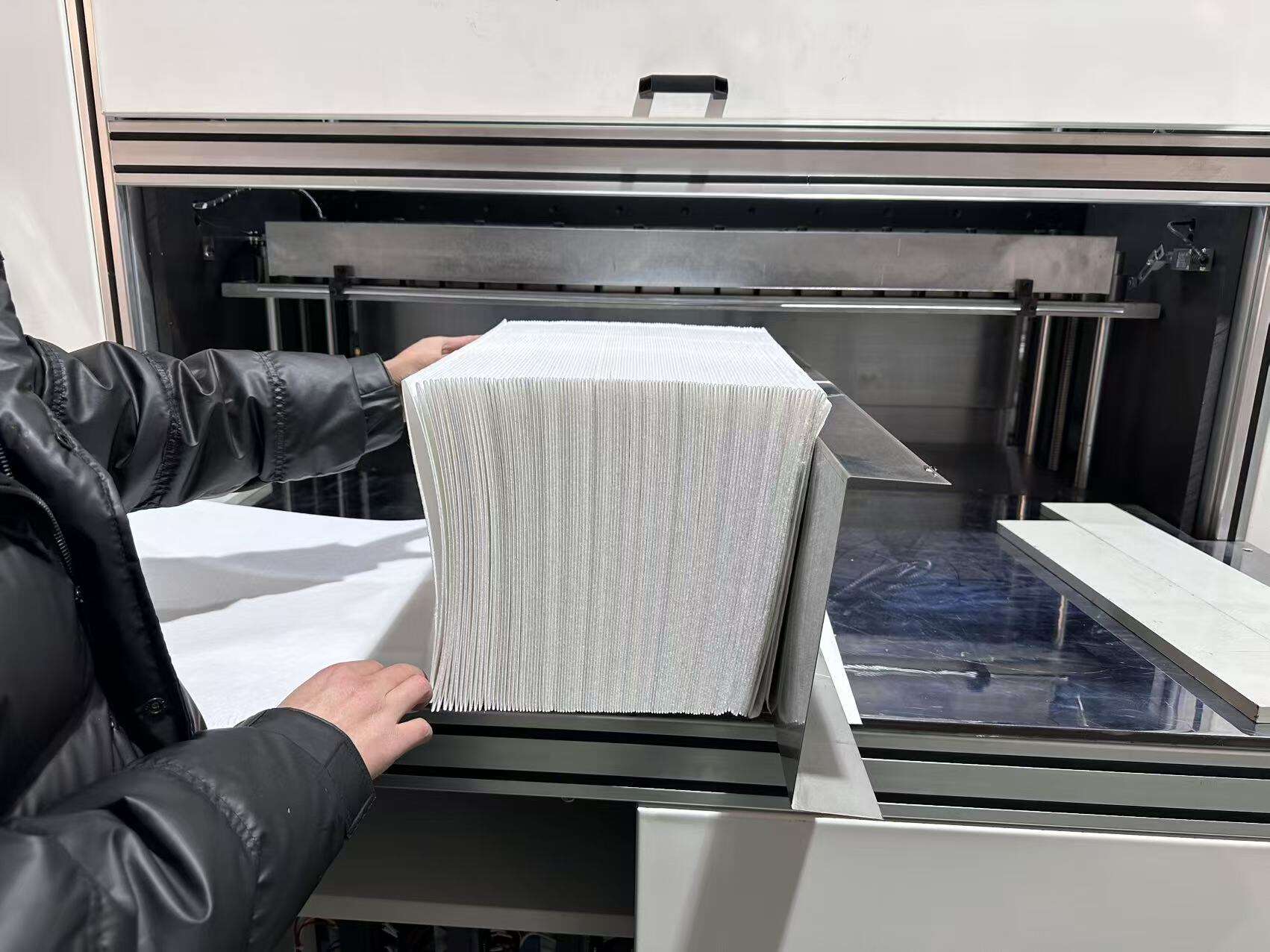

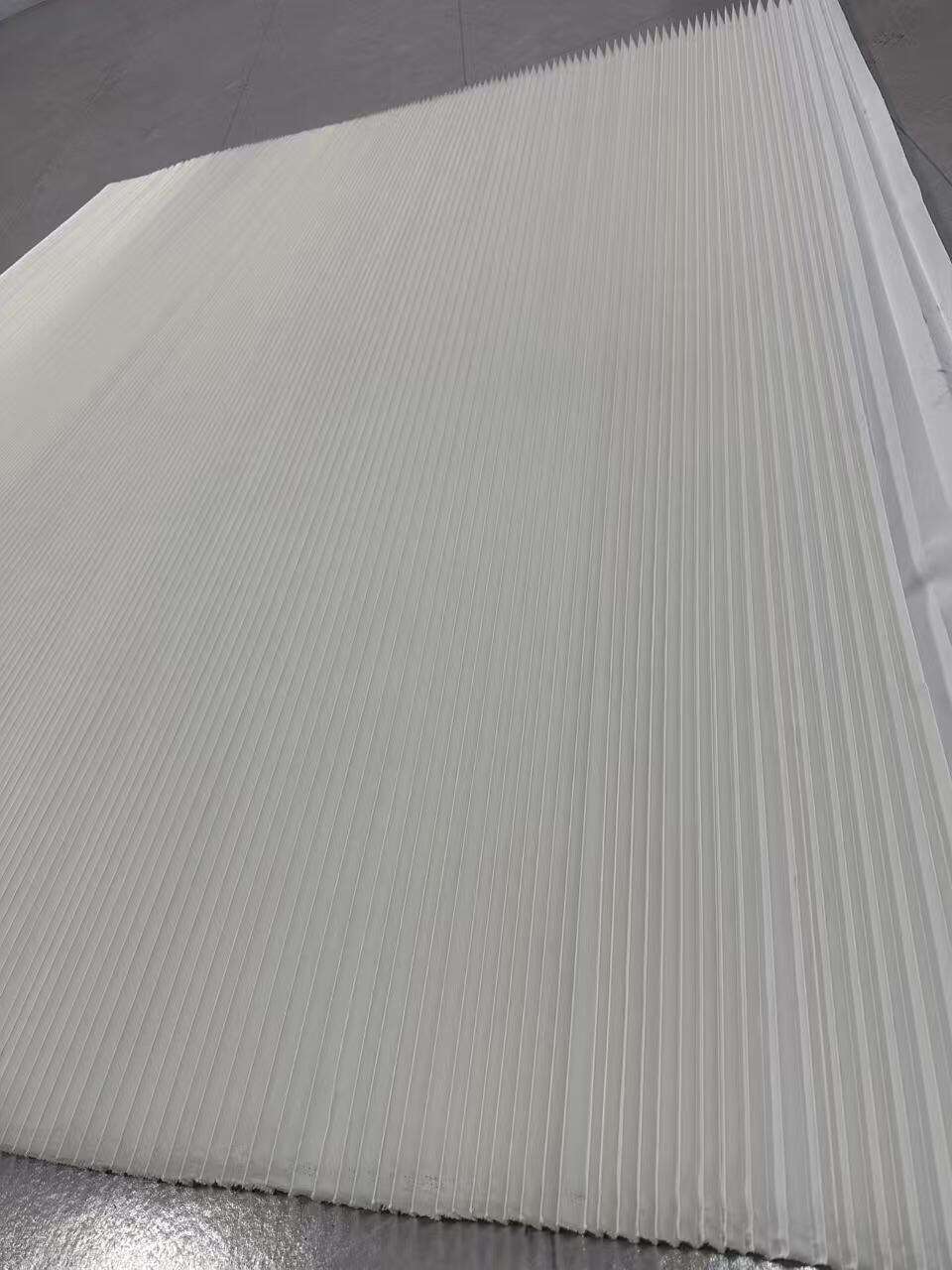

The petrol filter pleating machine represents a cornerstone of modern automotive filter manufacturing technology. This sophisticated equipment precisely creates uniform pleats in filter media, essential for producing high quality fuel filters that protect vehicle engines. The machine operates through a systematic process that begins with feeding flat filter material and transforms it into precisely pleated segments. Its advanced servo control system ensures accurate pleat depth, height, and spacing, maintaining consistency throughout the production cycle. The machine features automated tension control mechanisms that prevent material distortion while processing various filter media thicknesses. Operating at speeds of up to 50 meters per minute, it significantly enhances production efficiency while maintaining precise pleat geometries. The machine incorporates real time monitoring systems that track pleat parameters and automatically adjust settings to maintain quality standards. Its versatile design accommodates different filter media widths, typically ranging from 50mm to 1000mm, making it suitable for various automotive filter applications. The integrated heating system ensures optimal material conditioning for precise pleating, while the scoring mechanism creates clean, sharp pleats that maximize filter surface area and efficiency.