mosquito net pleating machine factory

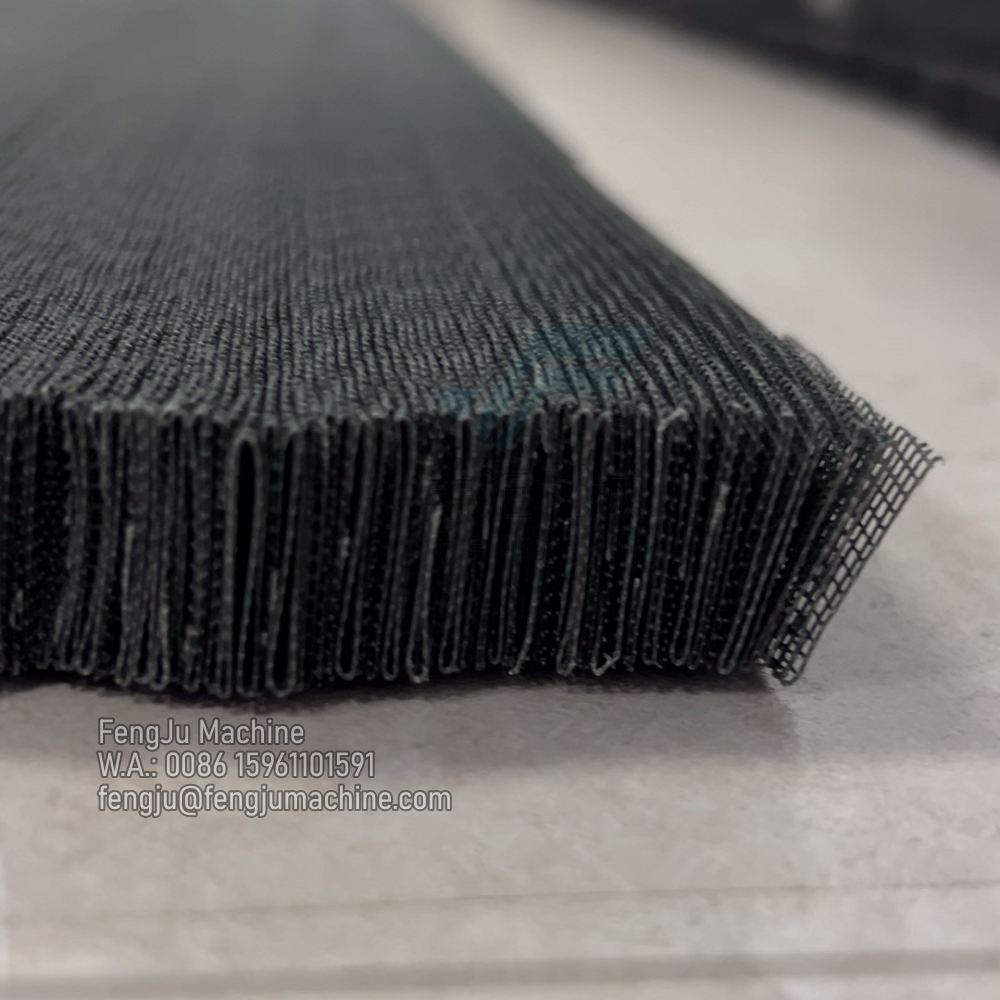

A mosquito net pleating machine factory represents a cutting-edge manufacturing facility dedicated to producing advanced equipment for the creation of pleated mesh products. The factory specializes in designing and manufacturing automated systems that transform flat mosquito netting materials into precisely pleated panels, essential for window screens, door screens, and other protective installations. These facilities integrate state-of-the-art pleating technology with quality control mechanisms to ensure consistent product output. The production line typically features automated feeding systems, precision pleating mechanisms, and thermal setting units that create durable, uniform pleats in the mesh material. The factory's machinery incorporates advanced servo motor systems for accurate pleat formation, alongside sophisticated tension control mechanisms to maintain material integrity throughout the process. Quality assurance stations are strategically positioned along the production line, utilizing optical scanning technology to detect any irregularities in pleat formation or material quality. The facility also houses research and development departments focused on innovating pleating techniques and improving production efficiency. Modern mosquito net pleating machine factories emphasize sustainable manufacturing practices, implementing energy-efficient systems and waste reduction protocols. They typically maintain climate-controlled production environments to ensure optimal material handling and processing conditions, resulting in superior quality pleated mesh products.