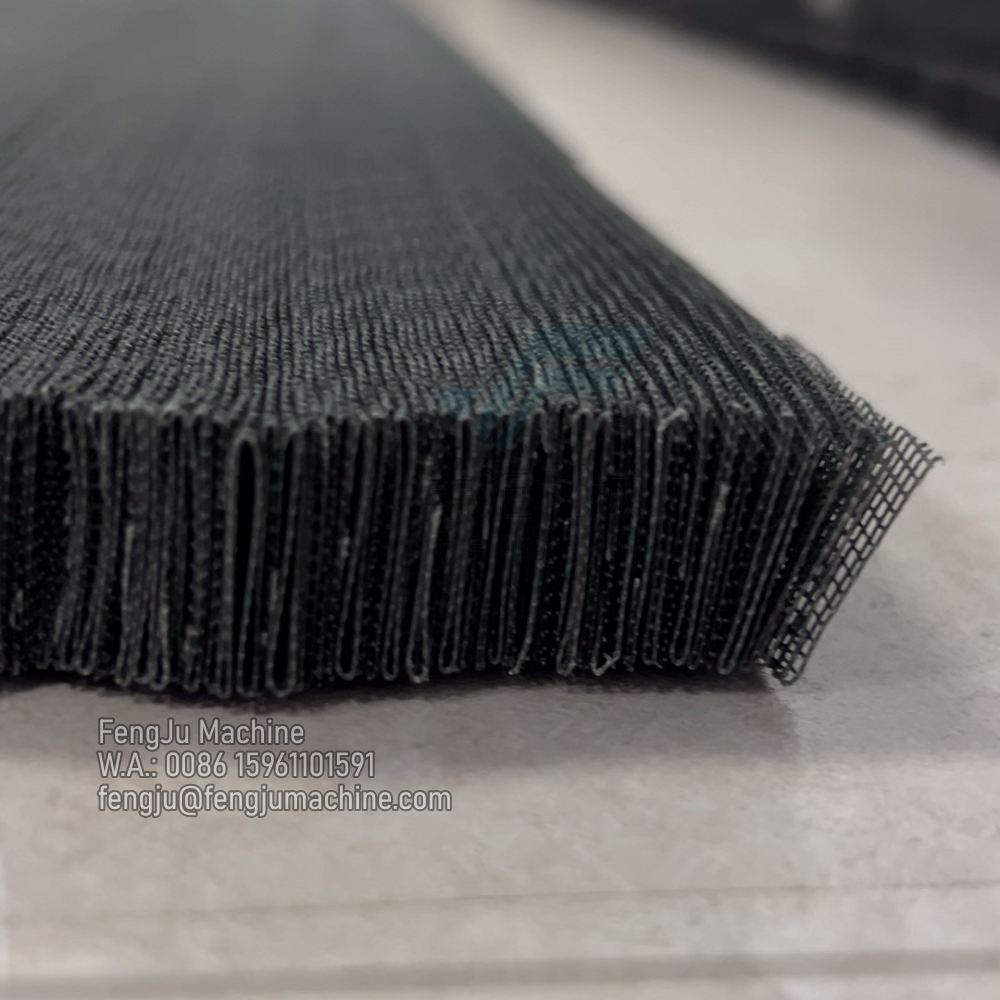

mosquito net pleating machine

The mosquito net pleating machine represents a significant advancement in textile manufacturing technology, specifically designed to create precise pleats in mosquito netting materials. This sophisticated equipment operates through a combination of mechanical and thermal processes, ensuring consistent pleat formation across various fabric widths. The machine features an automated feeding system that carefully guides the netting material through heated plates, which create permanent, uniform pleats at predetermined intervals. Its precision control system allows operators to adjust pleat depth, spacing, and pattern according to specific requirements. The machine incorporates advanced tension control mechanisms to prevent material distortion and ensure even pleating throughout the entire fabric length. With processing speeds of up to 50 meters per hour, it significantly enhances production efficiency while maintaining high quality standards. The equipment includes safety features such as emergency stop buttons and temperature monitoring systems to protect both operators and materials. It can accommodate different mesh sizes and material compositions, making it versatile for various mosquito net manufacturing applications. The machine's digital interface enables easy parameter adjustment and monitoring of the pleating process, ensuring consistent results across production batches.