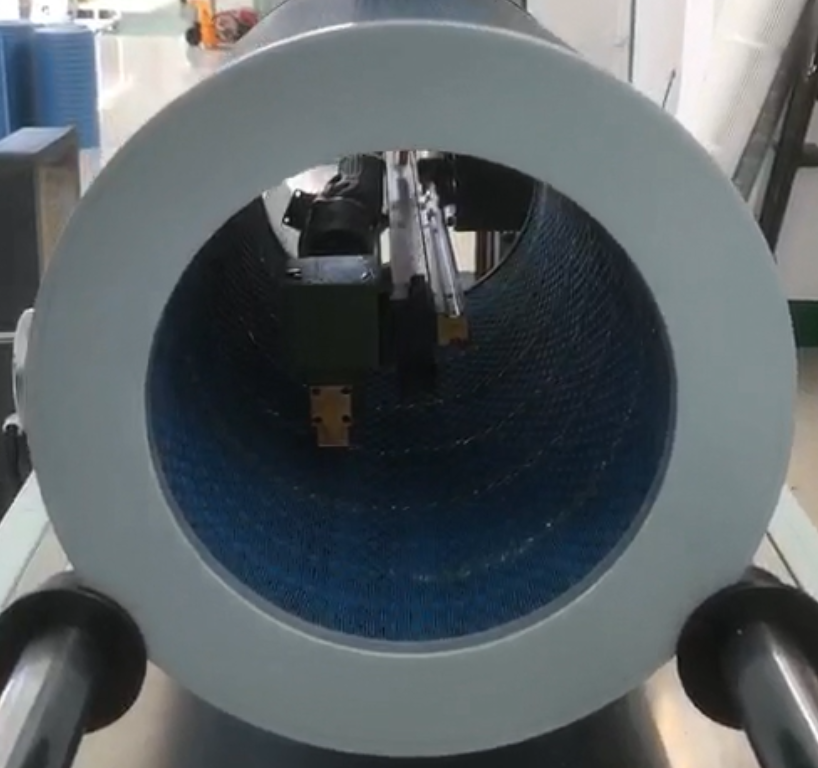

high-speed filter pleating machine

The high-speed filter pleating machine represents a breakthrough in filtration manufacturing technology, designed to meet the increasing demands of modern industrial applications. This advanced equipment efficiently creates precise pleats in various filter media materials, including paper, synthetic materials, and composite fabrics. Operating at speeds of up to 200 pleats per minute, the machine incorporates sophisticated servo motor controls and automated tension management systems to ensure consistent pleat height and spacing. Its versatile design accommodates different filter media widths ranging from 100mm to 2000mm, making it suitable for producing automotive filters, HVAC systems, and industrial air filtration units. The machine features an intelligent scoring system that prevents material damage while maintaining optimal pleat geometry, alongside a user-friendly touch-screen interface for easy operation and parameter adjustment. Built-in quality control sensors continuously monitor pleat formation and material alignment, ensuring production consistency and reducing waste. The system also includes automated cutting mechanisms and optional hot-melt adhesive applications for complete filter panel assembly.