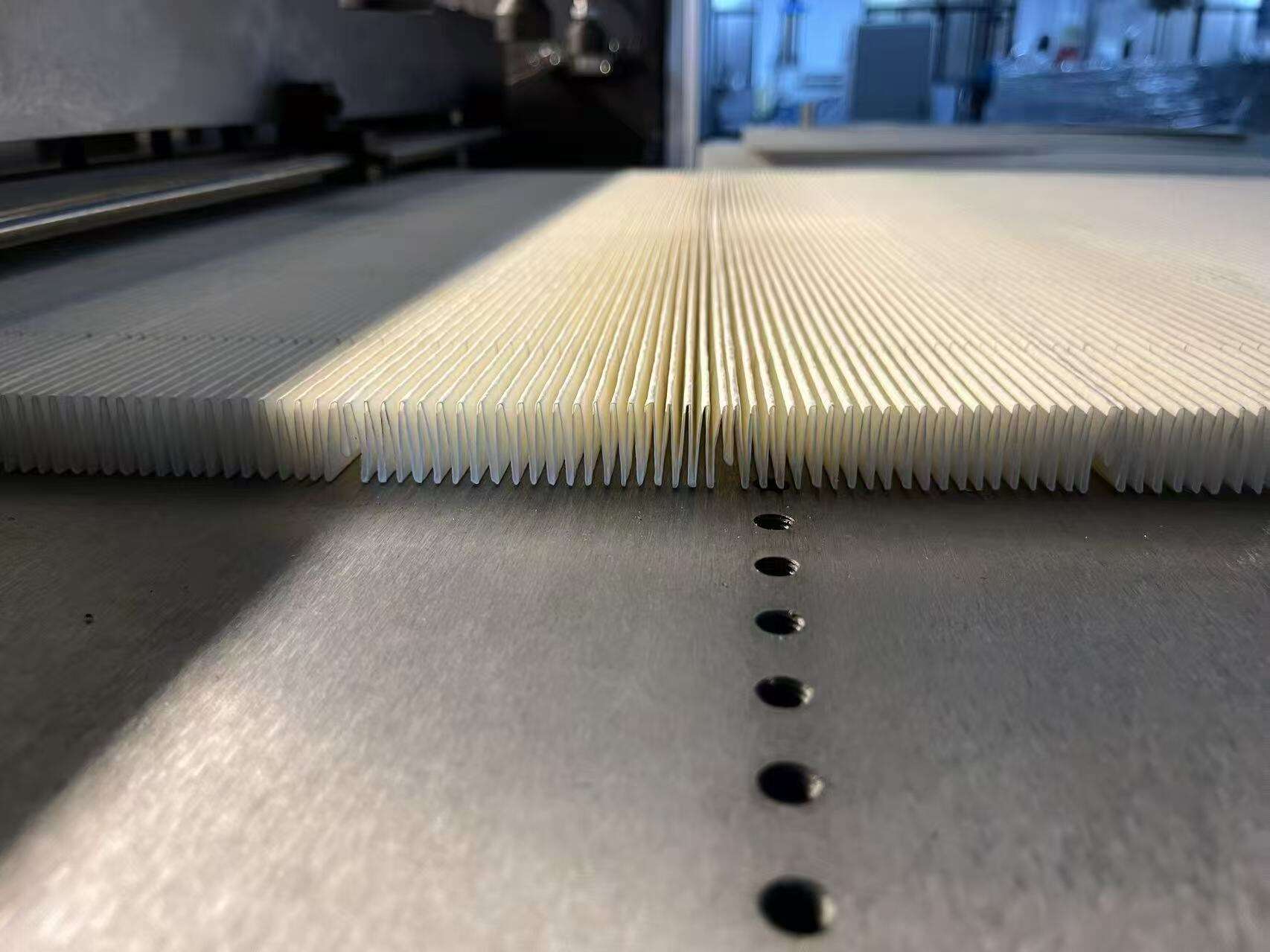

fuel filter pleating machine

The fuel filter pleating machine represents a sophisticated piece of manufacturing equipment designed to produce high-quality pleated filter elements for automotive and industrial applications. This advanced machinery precisely folds filter media into uniform pleats, creating maximum filtration surface area within a compact space. The machine operates through a systematic process that begins with feeding raw filter material through precision rollers, followed by carefully controlled heating elements that help maintain consistent pleat geometry. Its computerized control system ensures exact pleat depth, spacing, and count, while maintaining production speeds of up to 50 meters per minute. The machine incorporates advanced scoring technology that creates precise fold lines without damaging the filter media, ensuring optimal filtration performance. Additionally, it features automated tension control systems that maintain consistent material feed, resulting in uniform pleat formation throughout the entire production run. The equipment can handle various filter media types, including cellulose, synthetic, and composite materials, with thicknesses ranging from 0.2 to 0.8 mm. Modern fuel filter pleating machines are equipped with quality monitoring systems that continuously assess pleat uniformity and automatically adjust processing parameters to maintain consistent output quality.