mini cabin filter pleating machine

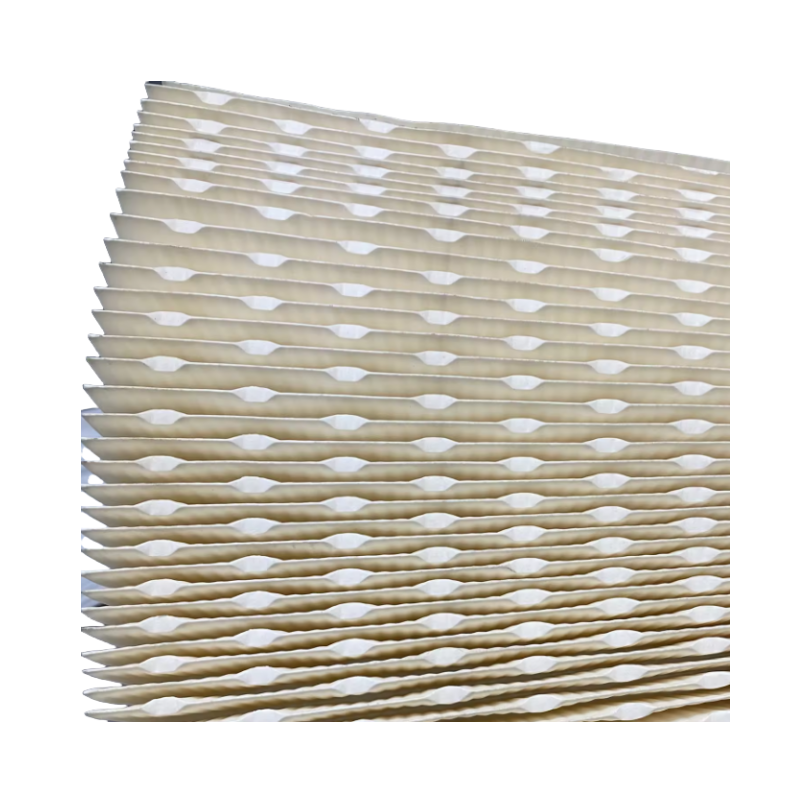

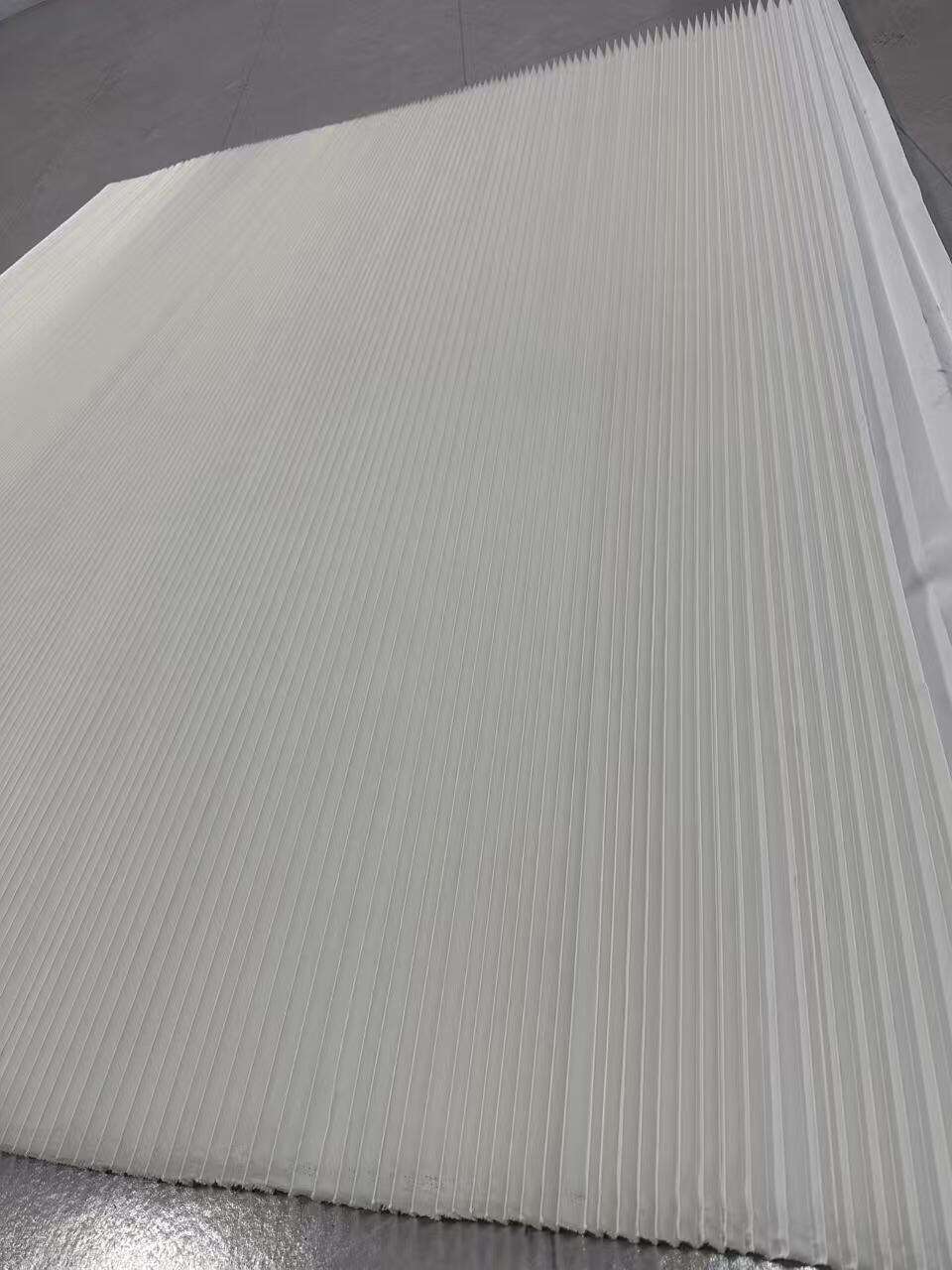

The mini cabin filter pleating machine represents a significant advancement in automotive filtration manufacturing technology. This compact yet powerful equipment is specifically designed to produce high-quality cabin air filters through precise pleating operations. The machine incorporates state-of-the-art pleating technology that ensures consistent fold patterns and optimal pleat depth, essential for maximizing filtration efficiency. Operating at speeds of up to 40 meters per minute, it can handle various filter media materials, including synthetic fibers, activated carbon-embedded materials, and multilayer composites. The machine features an advanced scoring system that creates precise pleat lines, ensuring uniform pleat formation and optimal filter performance. Its automated tensioning system maintains consistent material feed throughout the pleating process, preventing material waste and ensuring quality output. The digital control interface allows operators to easily adjust pleat height, pitch, and speed parameters, making it versatile for different filter specifications. Additionally, the machine is equipped with an automatic counting system and cutting mechanism, streamlining the production process and maintaining precise filter dimensions.