3000mm fly screen pleating machine manufacturer

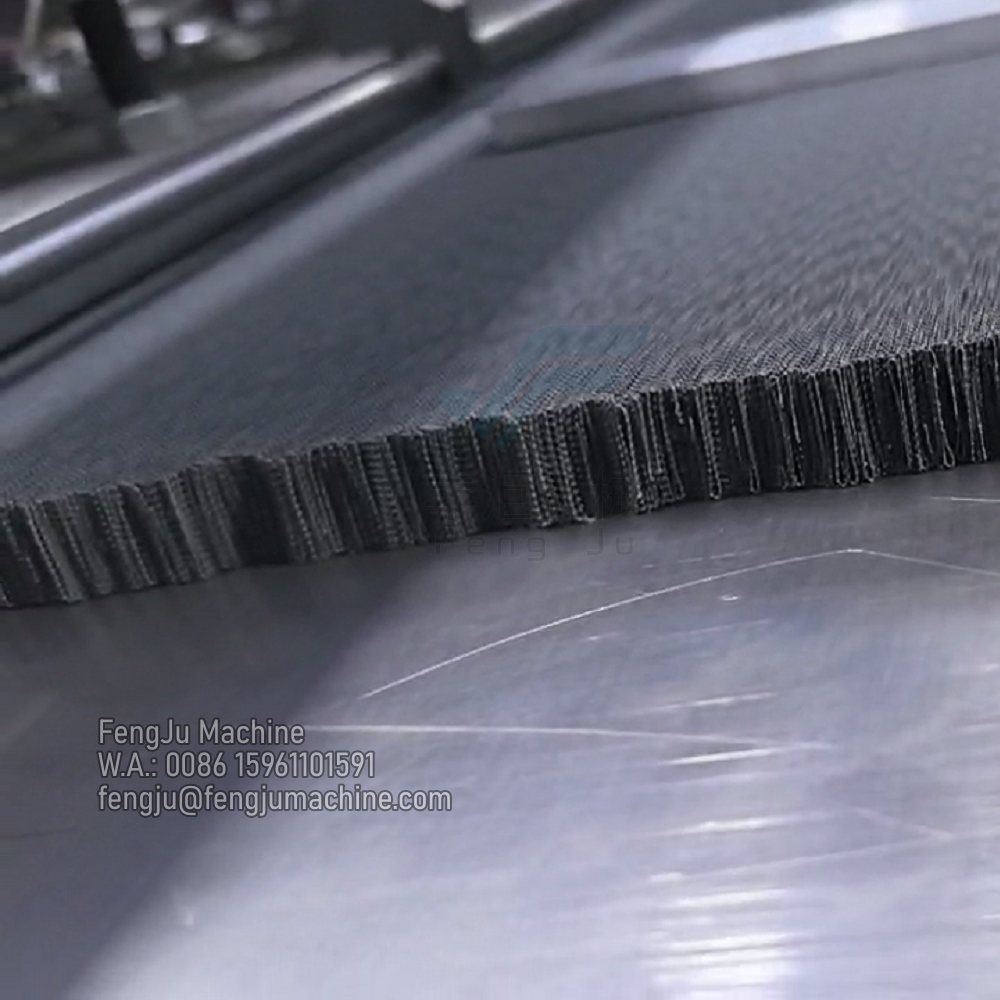

The 3000mm fly screen pleating machine manufacturer stands at the forefront of window screening technology, offering state-of-the-art equipment designed for high-volume production environments. This advanced machinery specializes in the precise pleating of mesh materials up to 3000mm in width, delivering consistent and accurate results for professional screen manufacturing. The machine incorporates sophisticated servo motor systems that ensure precise control over pleating depths and spacing, while maintaining optimal tension throughout the process. Its automated feeding mechanism guarantees smooth material handling, reducing waste and improving production efficiency. The manufacturer has integrated smart control systems with user-friendly interfaces, allowing operators to easily adjust parameters and monitor production metrics in real-time. The robust construction includes hardened steel components and precision-engineered parts that ensure longevity and reliability. With production speeds reaching up to 50 meters per hour, this equipment significantly enhances manufacturing capabilities while maintaining exceptional quality standards. The machine is equipped with advanced safety features and emergency stop mechanisms, prioritizing operator safety without compromising productivity.