tulle pleating machine

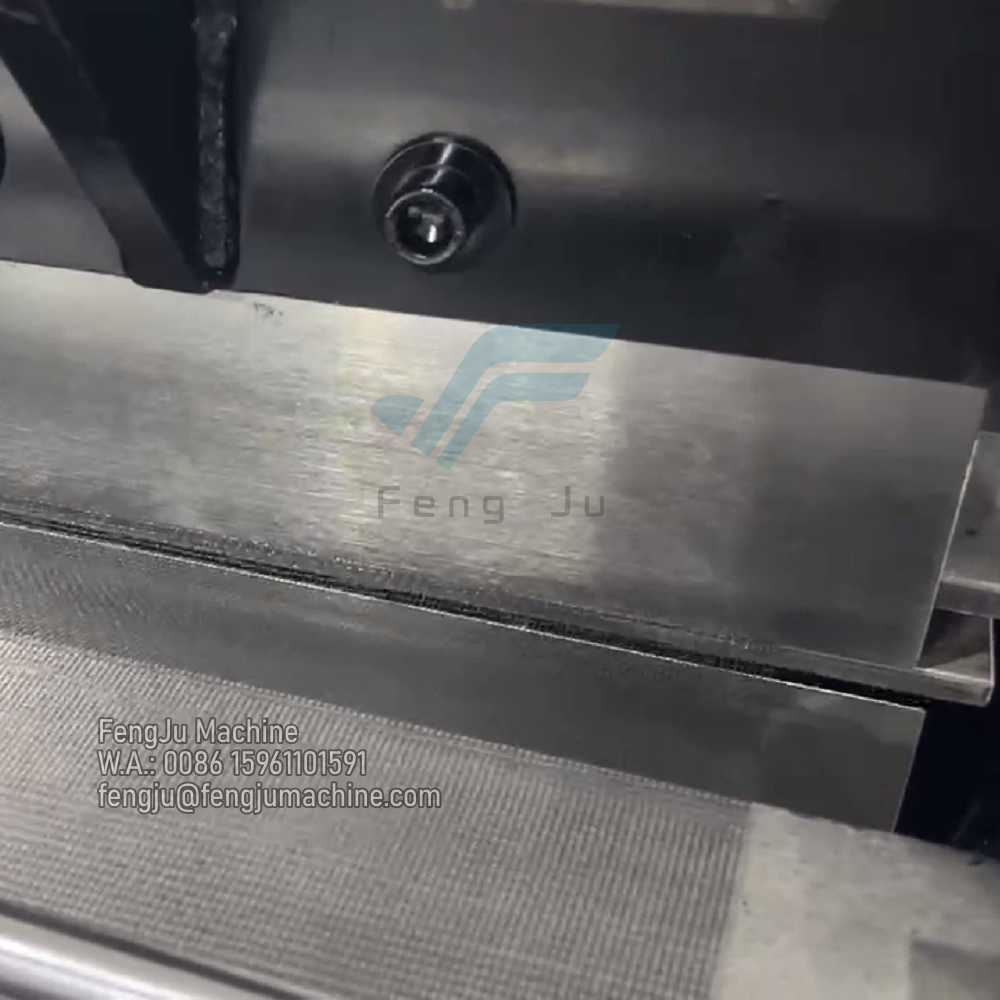

The tulle pleating machine represents a significant advancement in textile processing technology, specifically designed to create precise and consistent pleats in tulle fabric. This sophisticated equipment combines mechanical precision with customizable settings to transform flat tulle into beautifully pleated materials suitable for various applications. The machine features an innovative feeding system that carefully guides the tulle through a series of heated plates and rollers, ensuring uniform pleat formation without damaging the delicate fabric structure. Its digital control panel allows operators to adjust key parameters such as pleat depth, spacing, and temperature, enabling the production of diverse pleat patterns to meet different design requirements. The machine's processing capacity typically ranges from 5 to 20 meters per minute, depending on the pleat specifications and fabric type. Advanced tension control mechanisms maintain fabric stability throughout the pleating process, while the temperature regulation system ensures optimal heat distribution for lasting pleat retention. The machine accommodates various tulle widths and can process both synthetic and natural fiber-based tulle materials, making it versatile for different production needs.