small batch oil filter production line

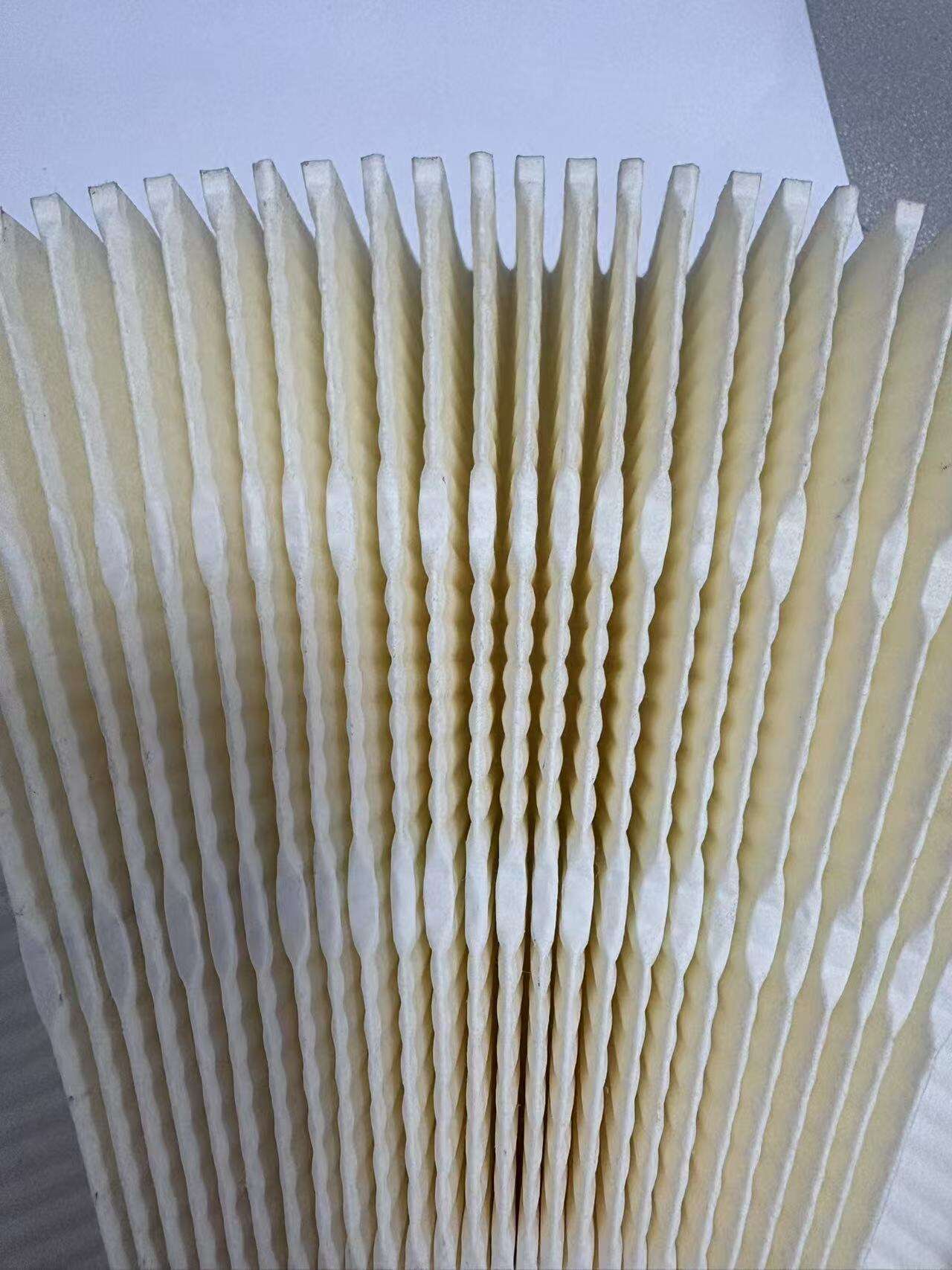

The small batch oil filter production line represents a sophisticated manufacturing solution designed specifically for businesses seeking flexible and efficient oil filter manufacturing capabilities. This advanced system integrates multiple production stages, including metal processing, pleating, assembly, and quality control, all within a compact footprint. The line efficiently handles the complete manufacturing process, from raw material preparation to final product packaging, with precise control over each production phase. Its modular design allows for easy configuration based on specific production requirements, accommodating various filter sizes and types. The system incorporates advanced automation technologies, ensuring consistent quality while maintaining operational efficiency. Key technological features include computerized pleating control, automated adhesive application, and integrated quality inspection systems. The production line is particularly well-suited for manufacturers requiring quick product changeovers and small to medium production runs. It maintains high precision in critical processes such as end cap bonding, media pleating, and element assembly, ensuring each filter meets strict quality standards. This versatile system can produce automotive, industrial, and hydraulic filters, making it an ideal solution for both specialized filter manufacturers and companies looking to expand their product range.