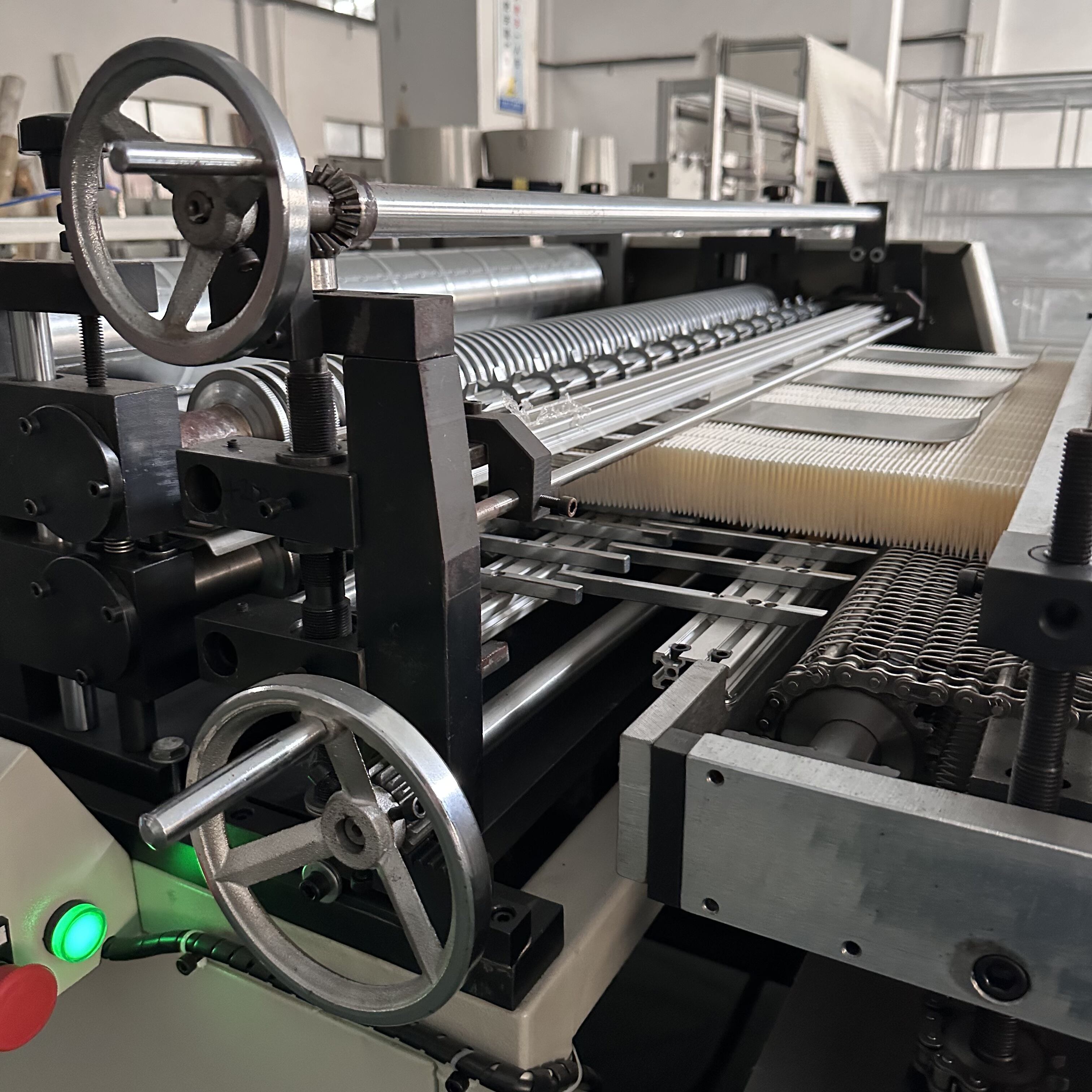

metal mesh oil filter production line

The metal mesh oil filter production line represents a state-of-the-art manufacturing system designed to create high-quality oil filtration solutions for various industrial applications. This advanced production line integrates multiple processes including metal mesh preparation, pleating, frame assembly, and quality inspection stations. The system employs precision cutting technology to ensure accurate mesh sizes, while automated pleating machines create uniform patterns that maximize filtration efficiency. The production line features sophisticated welding stations for secure frame attachment and incorporates real-time quality control measures throughout the manufacturing process. Its modular design allows for flexible production capacity, capable of producing filters ranging from small automotive applications to large industrial systems. The line utilizes advanced materials handling systems and automated conveyor networks to maintain consistent production flow and minimize manual intervention. Quality control checkpoints are strategically positioned to monitor mesh integrity, pleat uniformity, and overall filter assembly quality. The system's programmable logic controllers (PLCs) enable precise adjustment of production parameters to meet varying specifications and quality standards. This comprehensive production solution delivers consistent, high-quality metal mesh oil filters while maintaining optimal operational efficiency and reducing material waste.