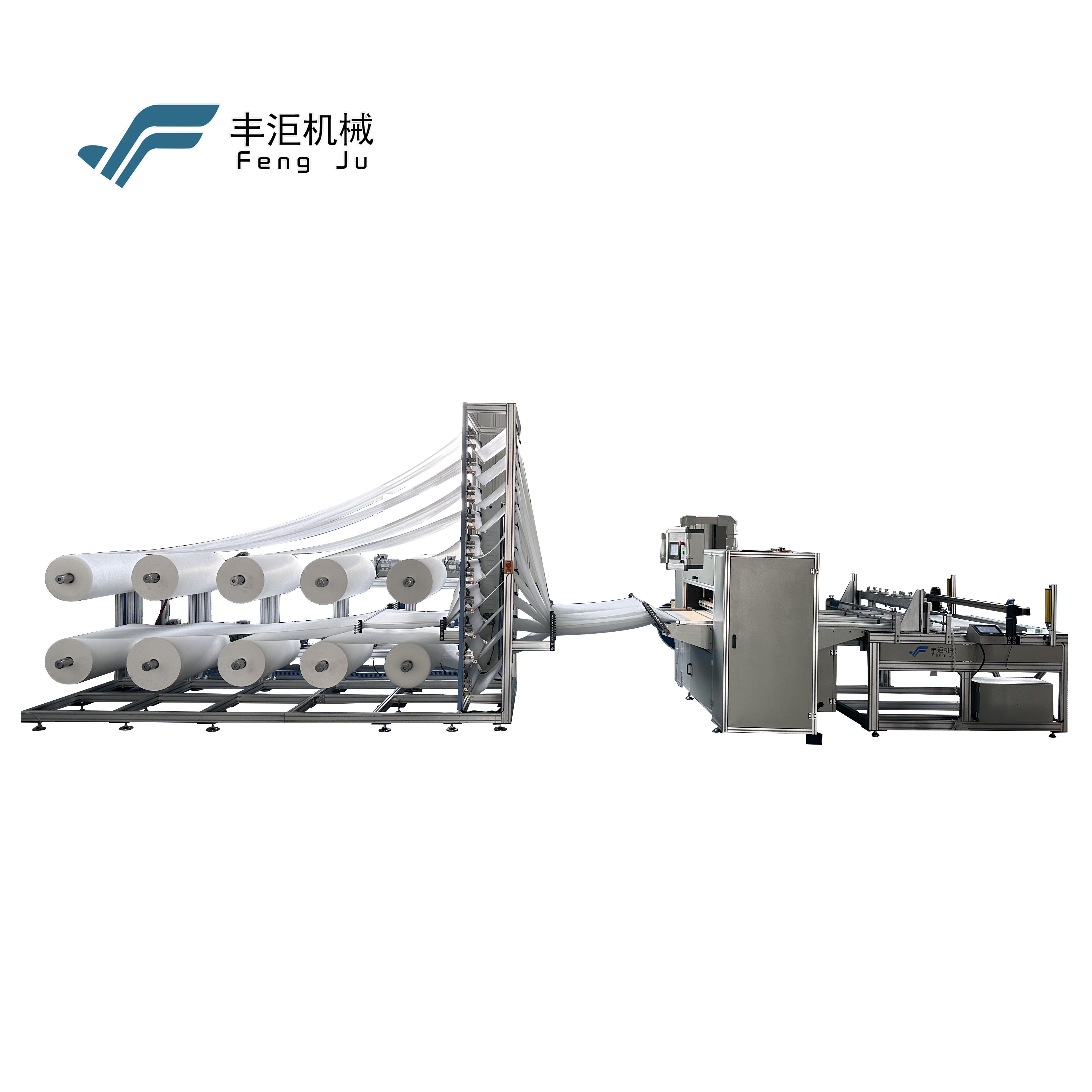

motorized liquid filter pleating machine

The motorized liquid filter pleating machine represents a pinnacle of modern filtration technology, designed to create precise pleats in filter media for liquid filtration applications. This advanced equipment utilizes a sophisticated motorized system that ensures consistent pleat formation and spacing, crucial for optimal filter performance. The machine incorporates precision-controlled motors that drive the pleating mechanism, allowing for adjustable pleat heights ranging from 20mm to 100mm, with exceptional accuracy in pleat spacing. Its automated operation system includes programmable settings for different filter media types and pleat configurations, enabling versatile production capabilities. The machine can process various filter materials, including polypropylene, polyester, and cellulose-based media, making it suitable for diverse industrial applications. Featured with an intelligent tension control system, it maintains uniform material feed throughout the pleating process, preventing material stretching or damage. The integration of advanced scoring technology ensures clean, sharp pleats that maximize the filtration surface area while maintaining structural integrity. This machine is particularly valuable in the production of industrial liquid filters, automotive filters, and specialized filtration systems for chemical processing, where precision and consistency are paramount.