mosquito net pleating

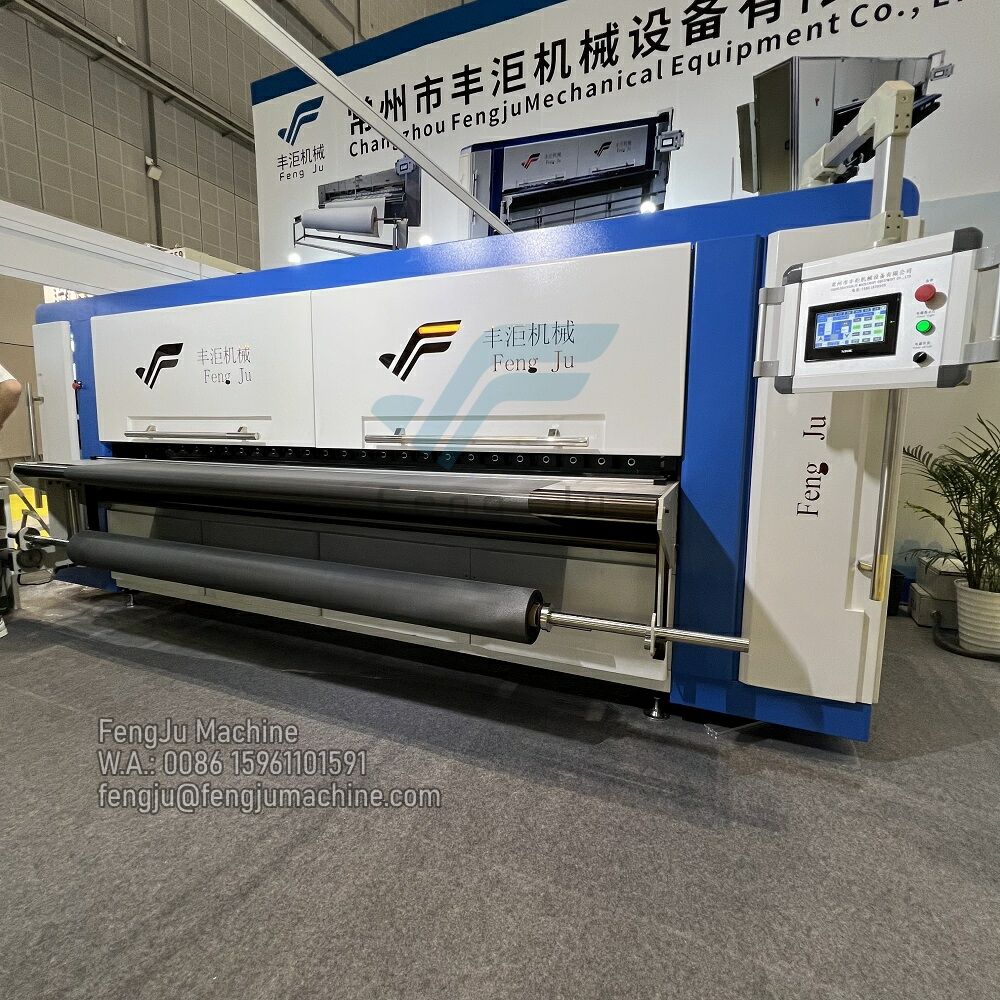

Mosquito net pleating represents a sophisticated manufacturing process that transforms flat netting material into precisely folded, accordion-style panels. This innovative technique creates a structured, space-efficient design that enhances both functionality and aesthetics. The pleating process involves careful manipulation of the mesh material through specialized machinery, resulting in uniform folds that can expand and contract smoothly. These pleated nets offer superior coverage and protection while maintaining excellent ventilation characteristics. The technology behind mosquito net pleating incorporates advanced thermal setting methods to ensure the pleats remain stable and durable over time. The pleated design allows for easy installation and operation, making it particularly suitable for various window types and sizes. The precision of the pleating process ensures consistent spacing between folds, optimizing both the protective barrier against insects and the visual appeal of the finished product. Modern pleating techniques also incorporate UV-resistant treatments and anti-static properties, extending the lifespan of the nets while maintaining their effectiveness. The applications range from residential windows and doors to commercial installations, with customizable options for different environmental conditions and specific requirements.