industrial paper pleating equipment

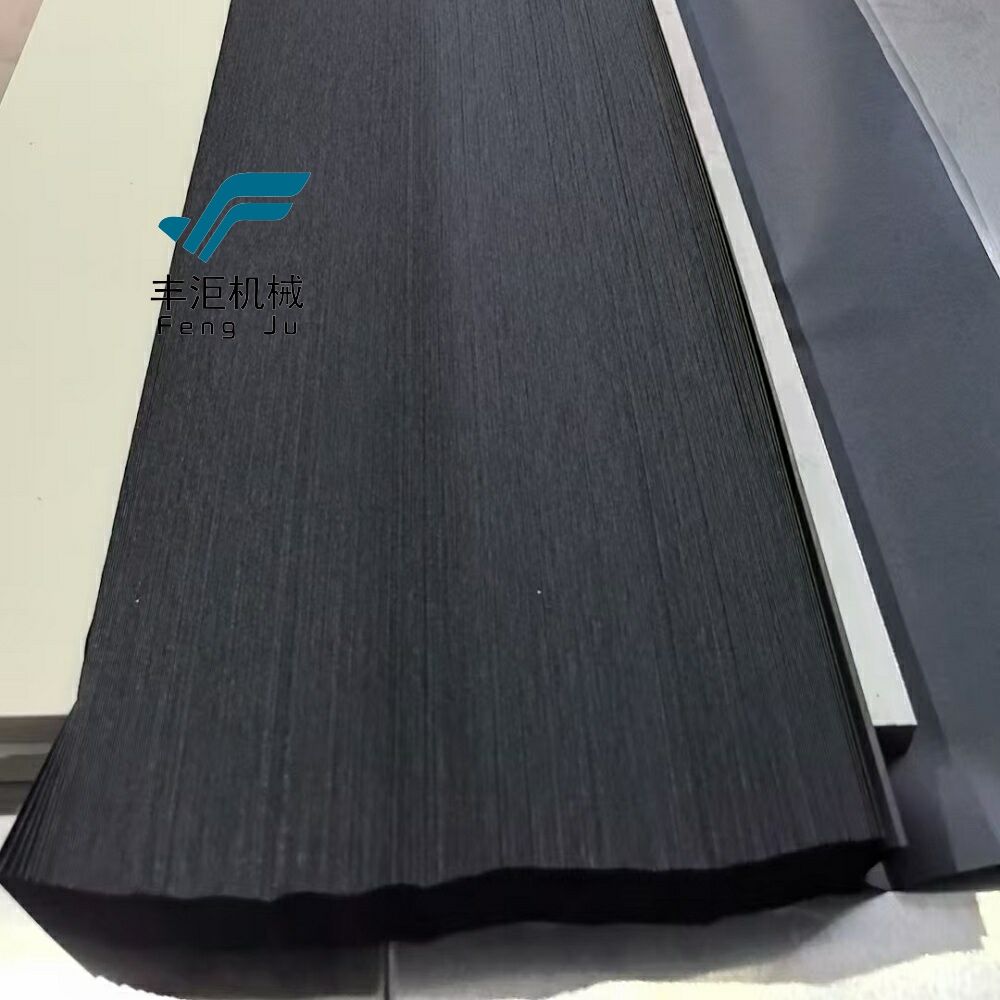

Industrial paper pleating equipment represents a cornerstone technology in modern manufacturing, designed to create precise, uniform pleats in various paper materials. These sophisticated machines combine mechanical precision with automated control systems to transform flat paper sheets into intricately pleated products. The equipment typically features adjustable pleat depth settings, variable speed controls, and automated feeding mechanisms to ensure consistent production quality. Core functions include material feeding, pleating formation, heat setting, and finished product collection. The technology incorporates advanced tension control systems and temperature monitoring to maintain precise pleat geometries across different paper grades and thicknesses. Applications span across multiple industries, including air filtration manufacturing, decorative paper product creation, and industrial filter production. The equipment can handle various paper types, from lightweight tissue to heavy-grade filter papers, with production speeds typically ranging from 50 to 200 pleats per minute. Modern systems often include digital interfaces for real-time monitoring and adjustment of pleating parameters, ensuring optimal performance and minimal material waste. The integration of smart sensors and quality control mechanisms helps maintain consistent pleat patterns and depths throughout extended production runs.