fully automated oil filter production line

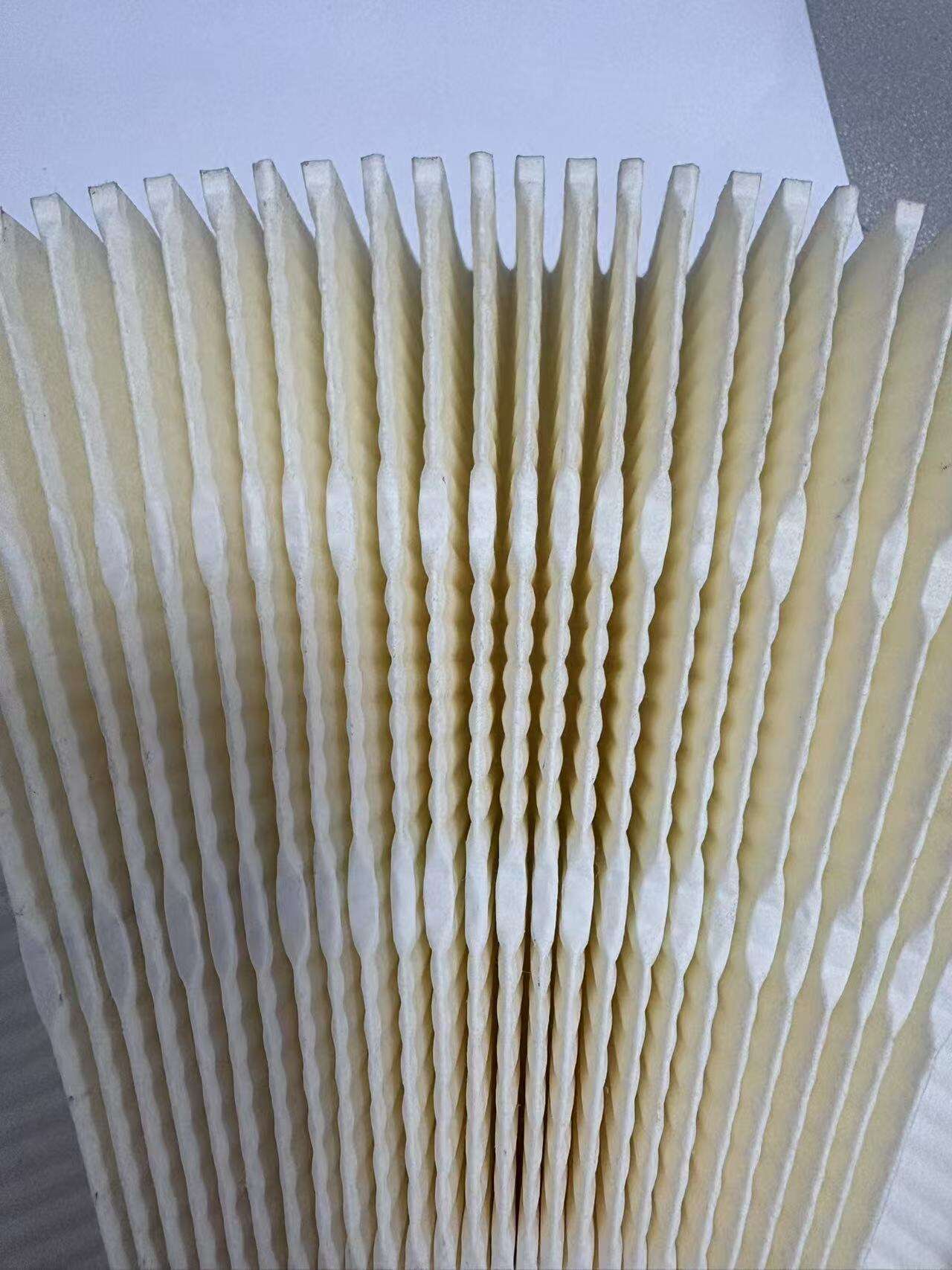

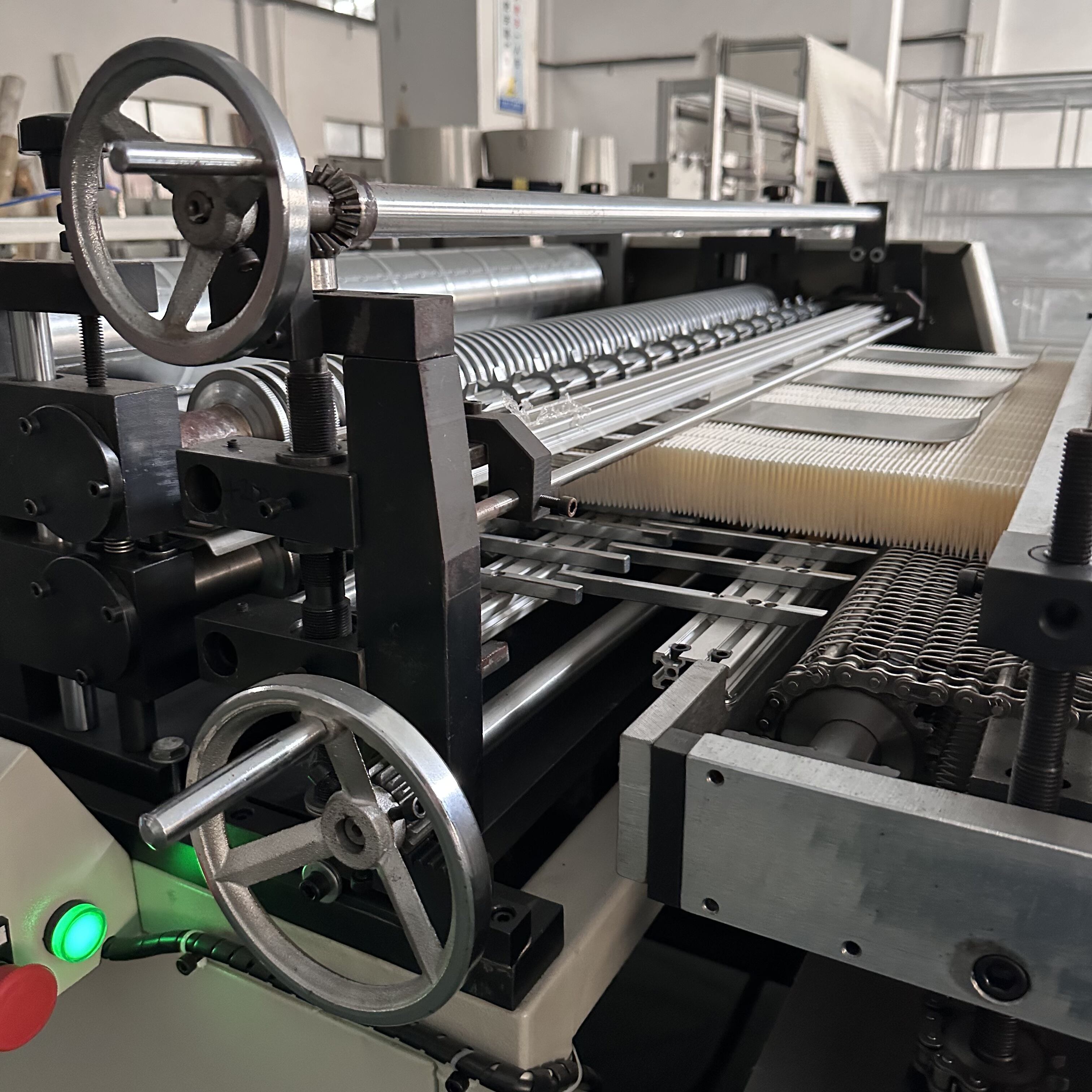

The fully automated oil filter production line represents a cutting-edge manufacturing solution designed to streamline the production of high-quality oil filters with minimal human intervention. This sophisticated system integrates multiple processes including metal processing, pleating, assembly, and quality control into a seamless operation. The production line features advanced robotics and precision machinery that handle everything from raw material feeding to final packaging. Its core components include automated pleating machines that create precise filter media folds, end cap assembly stations with thermal bonding capabilities, and sophisticated testing equipment for quality assurance. The system employs real-time monitoring through integrated sensors and advanced control systems, ensuring consistent product quality and optimal production efficiency. With a production capacity ranging from 1,000 to 5,000 units per shift, depending on filter specifications, this automated line significantly reduces labor costs while maintaining exceptional quality standards. The technology incorporates smart manufacturing principles, including IoT connectivity for remote monitoring and predictive maintenance capabilities. This production line is particularly suitable for medium to large-scale manufacturers serving automotive, industrial, and heavy machinery markets, where consistent quality and high production volumes are essential.