flymesh pleating machine manufacturer

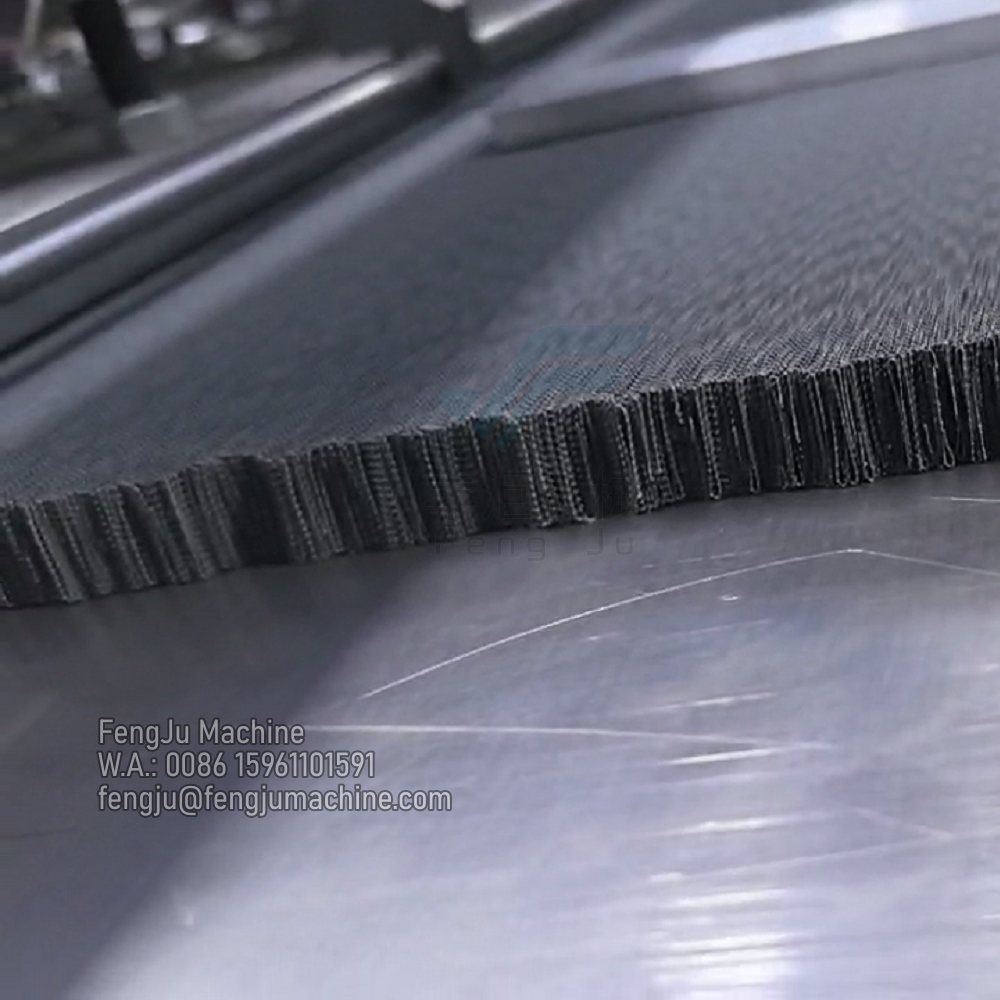

A flymesh pleating machine manufacturer stands at the forefront of industrial filtration technology, specializing in the production of sophisticated equipment designed to create precise pleated mesh materials. These advanced machines incorporate state-of-the-art pleating mechanisms that ensure consistent fold patterns and optimal material utilization. The manufacturer's expertise extends to developing customizable solutions that can handle various mesh materials, including stainless steel, aluminum, and synthetic compounds. The machines feature automated control systems with precise temperature regulation, adjustable pleating speeds, and programmable fold depths to accommodate different product specifications. Their equipment is engineered to maintain high production efficiency while ensuring superior pleat uniformity and structural integrity. The manufacturing facility employs rigorous quality control measures throughout the production process, from component selection to final assembly. With a focus on innovation, the manufacturer continuously updates their designs to incorporate the latest technological advancements, ensuring their machines remain competitive in the global market. These machines are particularly valuable in industries requiring high-performance filtration solutions, such as automotive, aerospace, HVAC systems, and industrial air purification. The manufacturer also provides comprehensive after-sales support, including installation guidance, maintenance training, and technical consultation.