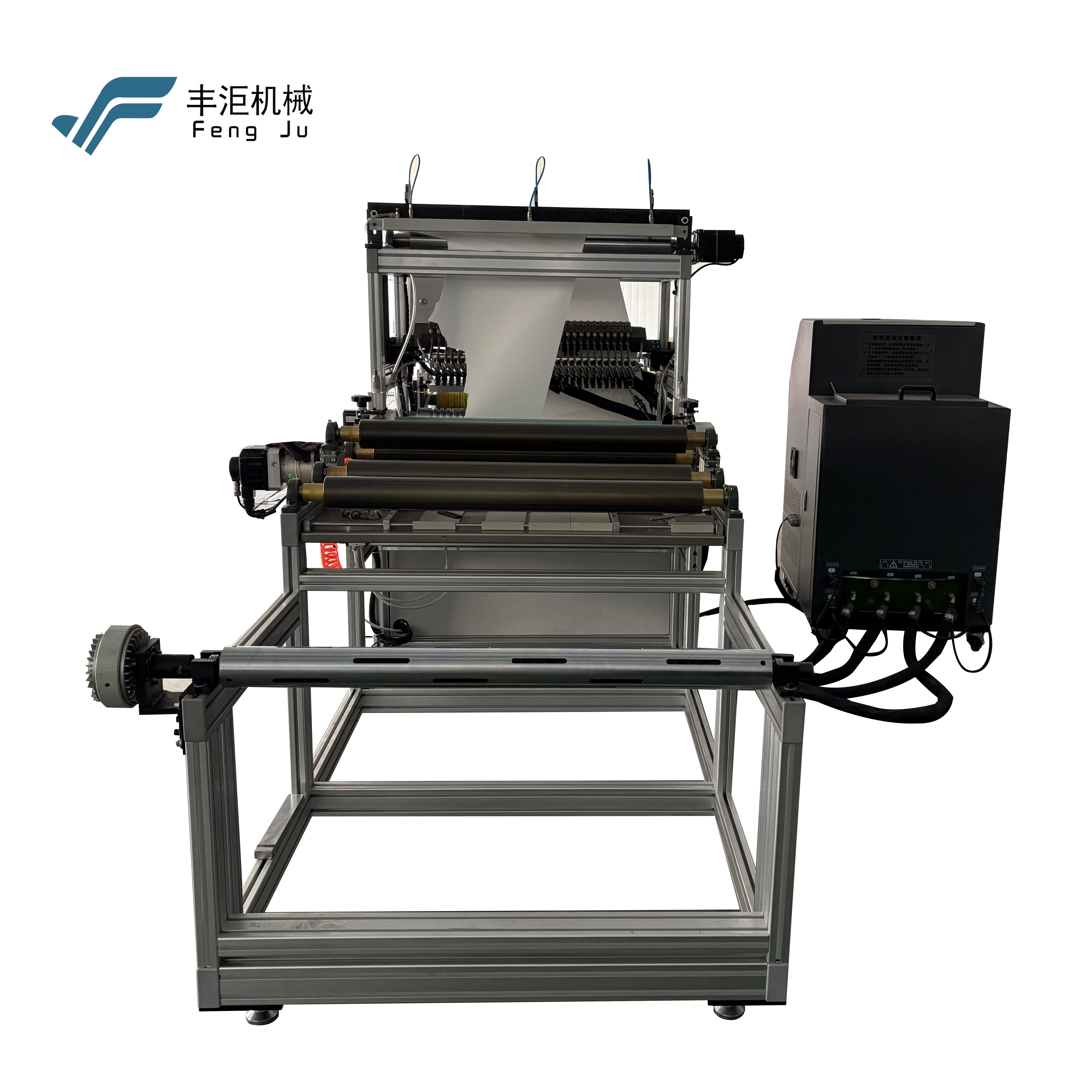

filter pleating

Filter pleating is an advanced manufacturing technique that significantly enhances filtration efficiency by creating accordion-like folds in filter media. This process maximizes the surface area available for filtration while maintaining a compact footprint. The pleating process involves precisely folding filter material into uniform pleats, creating multiple layers that effectively trap particles and contaminants. Modern filter pleating technology employs sophisticated machinery that ensures consistent pleat height, spacing, and density, crucial factors that directly impact filtration performance. The technology finds extensive applications across various industries, including HVAC systems, automotive air filters, industrial air purification, and liquid filtration systems. The pleated design allows for greater dirt-holding capacity, extended filter life, and improved air or liquid flow compared to flat filter media. The process accommodates various filter materials, from synthetic fibers to specialized membrane materials, each optimized for specific filtration requirements. The precision of modern pleating equipment ensures uniform pleat geometry, which is essential for maintaining consistent filtration efficiency throughout the filter's service life.