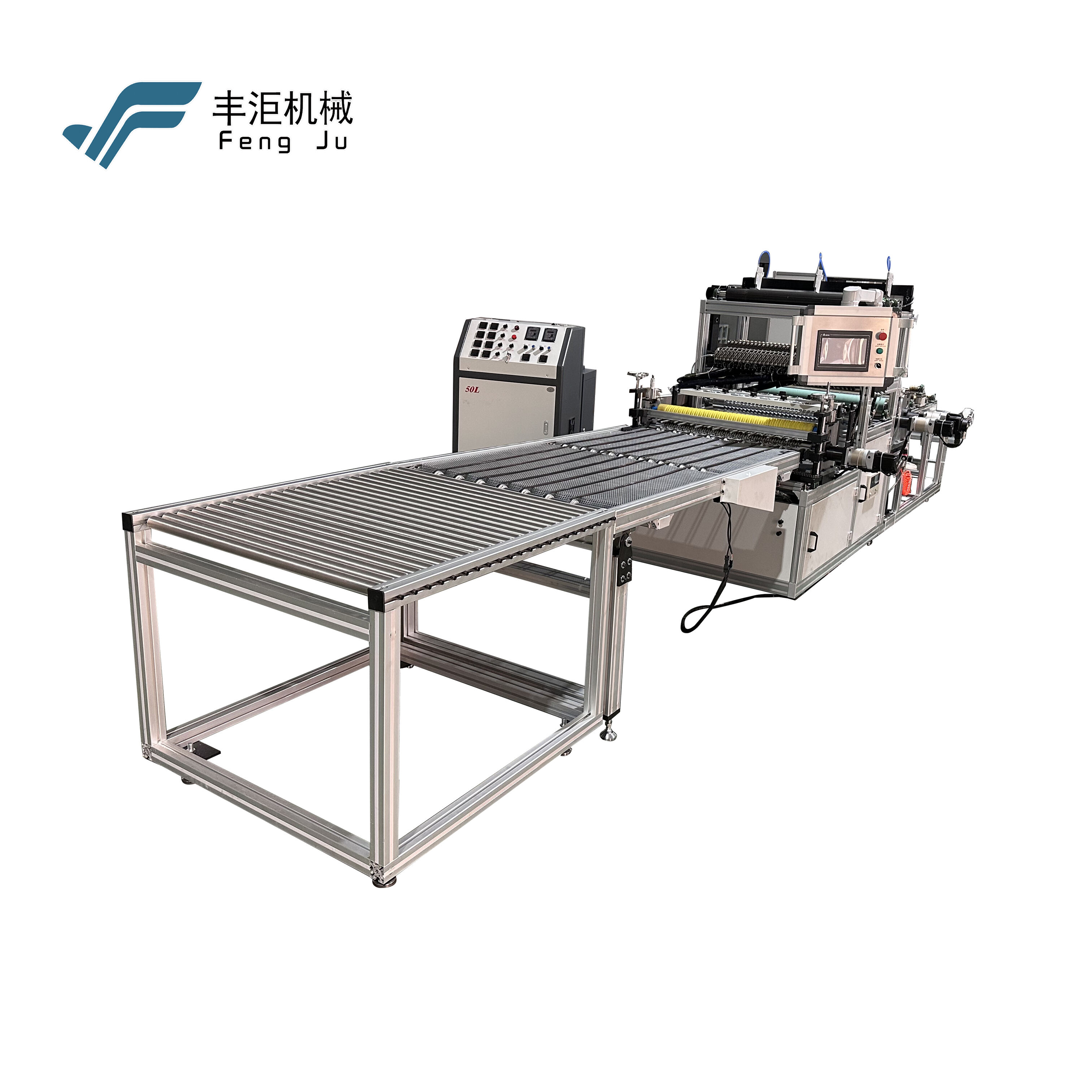

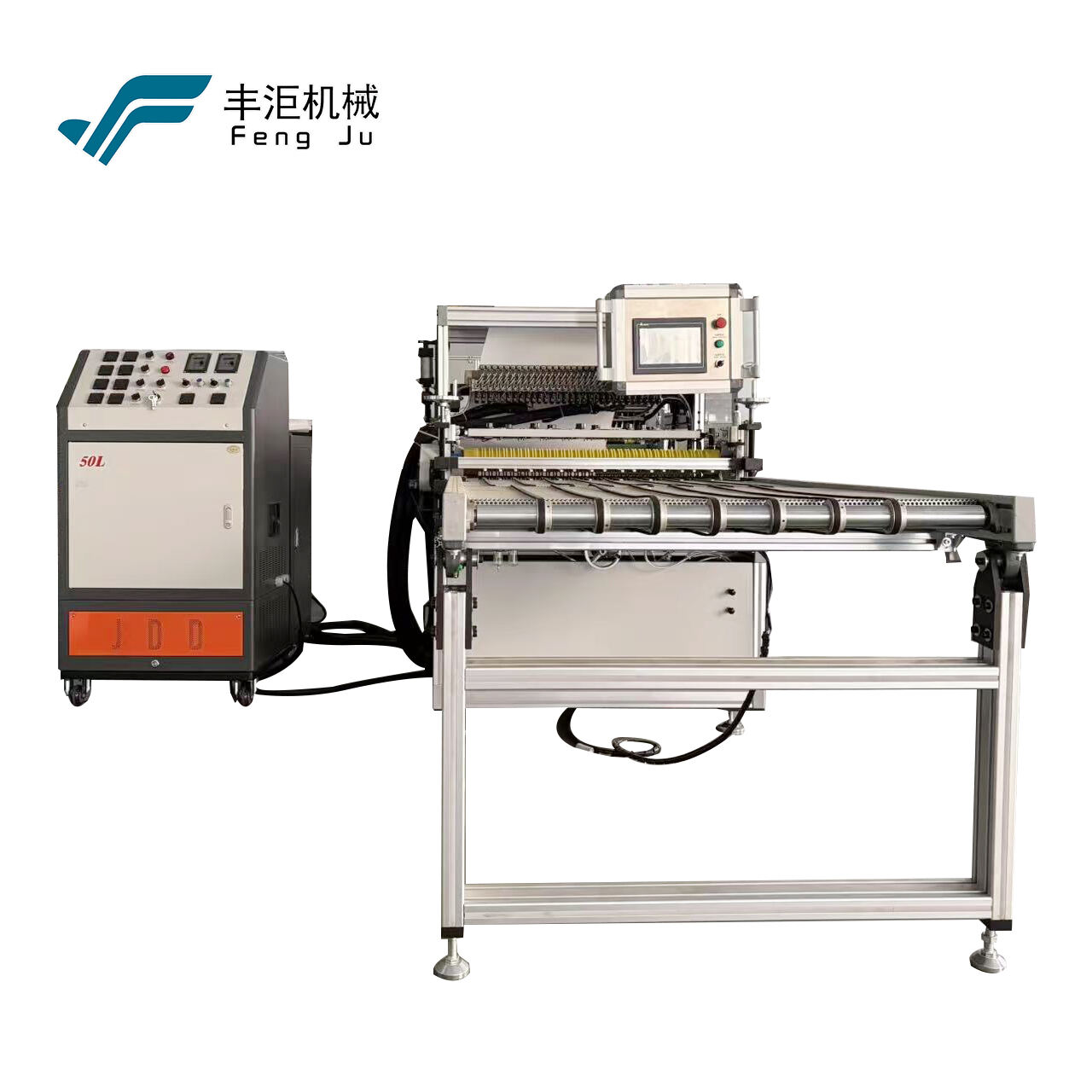

oil filter pleating

Oil filter pleating represents a crucial advancement in filtration technology, serving as the cornerstone of modern fluid purification systems. This innovative process involves creating precise accordion-like folds in filter media to maximize the surface area available for filtration while maintaining a compact design. The pleating process utilizes specialized machinery that forms uniform, geometrically optimized patterns, ensuring consistent spacing between each pleat. This configuration allows for superior particle capture efficiency and extended filter life. The technology incorporates various materials, including synthetic fibers, cellulose, and hybrid combinations, each selected for specific application requirements. Modern oil filter pleating implements advanced manufacturing techniques that optimize pleat density, height, and spacing to achieve optimal flow characteristics while maintaining structural integrity. The process considers factors such as fluid viscosity, flow rate requirements, and contaminant loading capacity to determine the ideal pleating configuration. These filters find extensive applications across automotive, industrial, and hydraulic systems, where they effectively remove harmful particles, metal shavings, and other contaminants from oil circuits. The precision of the pleating process directly influences filter performance, with careful attention paid to maintaining uniform pleat spacing and avoiding pinching or crowding that could compromise filtration efficiency.