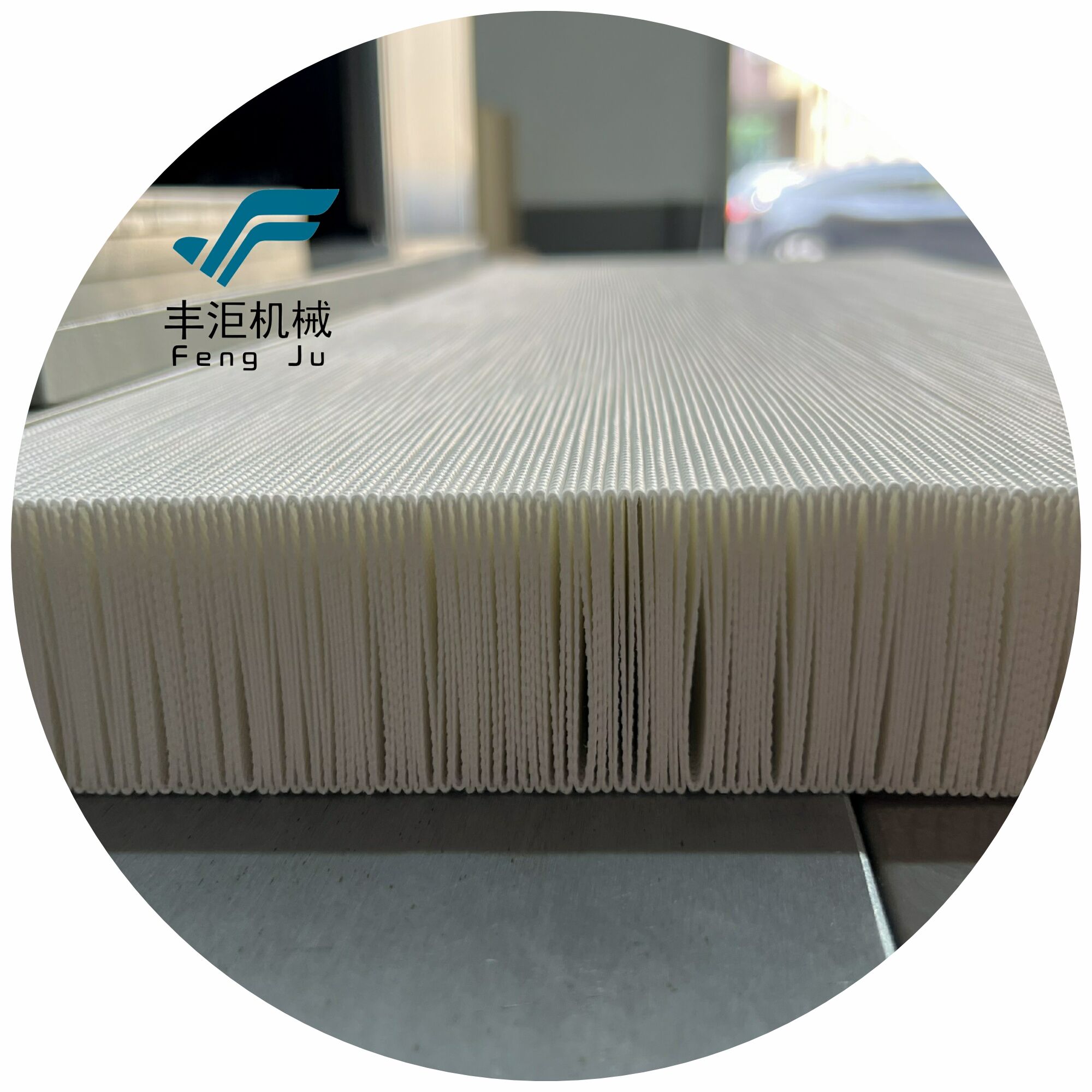

deep-pleat pleating machine

The deep-pleat pleating machine represents a significant advancement in textile processing technology, designed to create precise and uniform deep pleats in various fabric materials. This sophisticated equipment utilizes a combination of heat setting and mechanical pressure to form durable, well-defined pleats that maintain their shape over time. The machine features adjustable pleat depth settings, ranging from 1 inch to 4 inches, allowing for versatile pleating options to meet different manufacturing requirements. Its automated feeding system ensures consistent fabric alignment, while the temperature-controlled pressing mechanism guarantees optimal pleat formation. The machine incorporates advanced digital controls for precise temperature, pressure, and timing adjustments, enabling operators to achieve consistent results across different fabric types and weights. Applications span across multiple industries, including fashion garment manufacturing, home textile production, and industrial fabric processing. The system's efficient design allows for continuous operation, processing up to 200 meters of fabric per hour, making it ideal for both small-batch production and large-scale manufacturing operations. Additionally, the machine features an innovative cooling system that helps set pleats permanently while protecting delicate fabrics from heat damage.