blind pleating machine

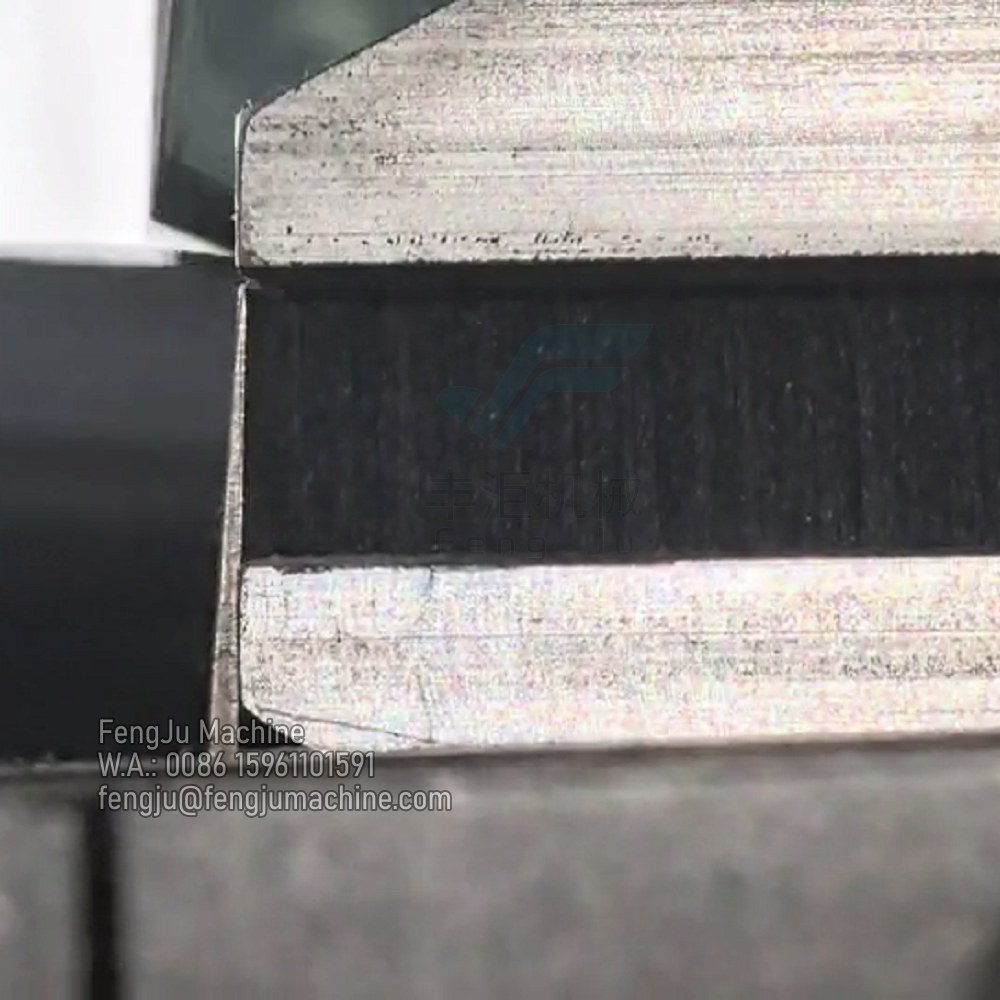

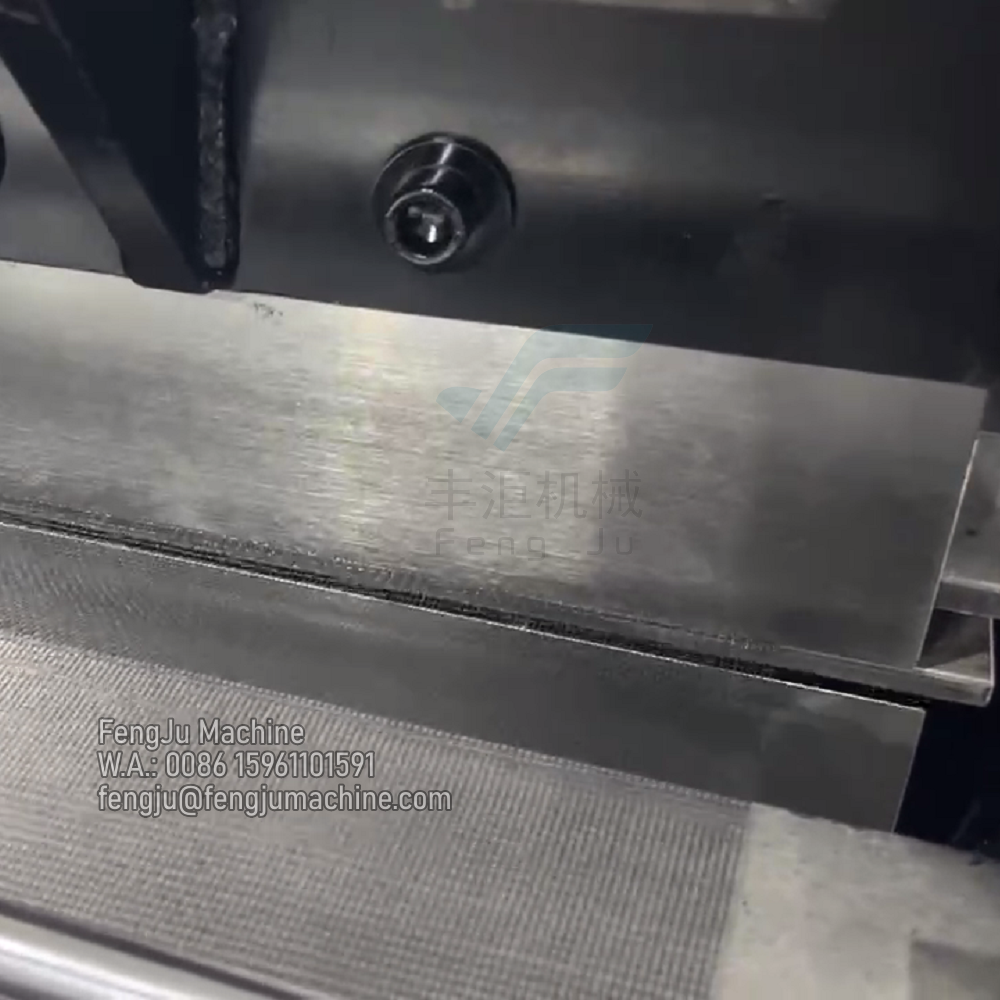

A blind pleating machine represents a sophisticated piece of manufacturing equipment designed specifically for creating precise, uniform pleats in window blinds and similar materials. This advanced machinery combines mechanical precision with automated controls to produce consistently high-quality pleated products. The machine operates by feeding material through a series of specially designed rollers and heating elements, which work in concert to create permanent, well-defined pleats. Its core technology includes precise temperature control systems, automated material feeding mechanisms, and adjustable pleat depth settings, allowing for customization according to specific product requirements. The machine can handle various material types, from lightweight fabrics to heavier materials used in window treatments. Modern blind pleating machines often incorporate digital controls that enable operators to program and store multiple pleat patterns and specifications, ensuring consistency across production runs. The system typically includes safety features such as emergency stops and temperature monitoring to protect both operators and materials. These machines significantly enhance production efficiency by automating what was traditionally a labor-intensive manual process, capable of processing hundreds of linear meters of material per hour while maintaining precise pleat dimensions and spacing.