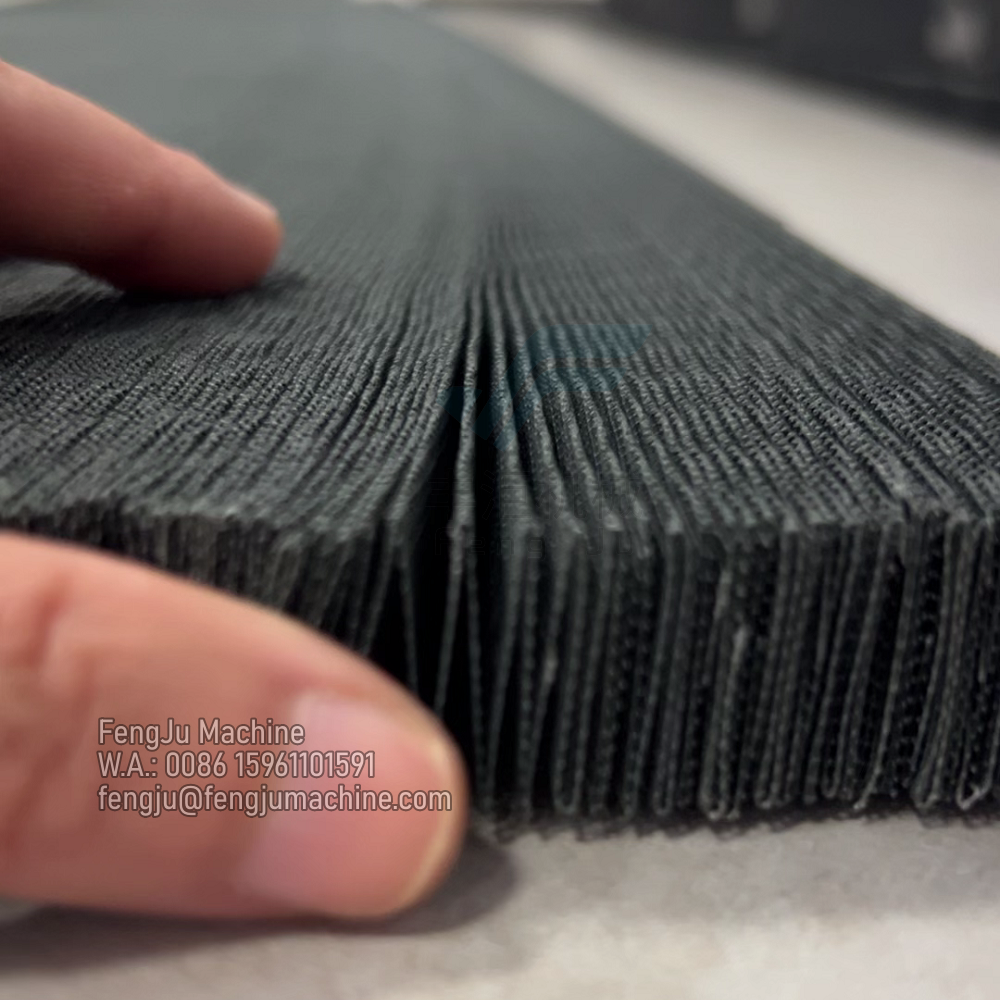

pleated mesh machine

The pleated mesh machine represents a cutting-edge solution in industrial filtration technology, designed to manufacture precision-engineered pleated mesh products with exceptional consistency and efficiency. This sophisticated equipment combines advanced mechanical engineering with automated control systems to transform flat mesh materials into carefully pleated configurations. The machine operates through a systematic process that includes material feeding, precise pleating, and automated cutting mechanisms, all controlled by programmable logic controllers (PLCs) for optimal accuracy. The technology incorporates adjustable pleating parameters, allowing for customization of pleat depth, spacing, and pattern according to specific application requirements. With processing capabilities for various mesh materials, including stainless steel, synthetic polymers, and composite materials, the machine can handle mesh widths ranging from narrow strips to industrial-scale sheets. Its versatility extends to applications across multiple industries, including automotive filtration, HVAC systems, water treatment facilities, and industrial air purification systems. The machine's integrated quality control systems ensure consistent pleat formation and material integrity throughout the production process, while its advanced safety features protect operators and maintain workplace safety standards.