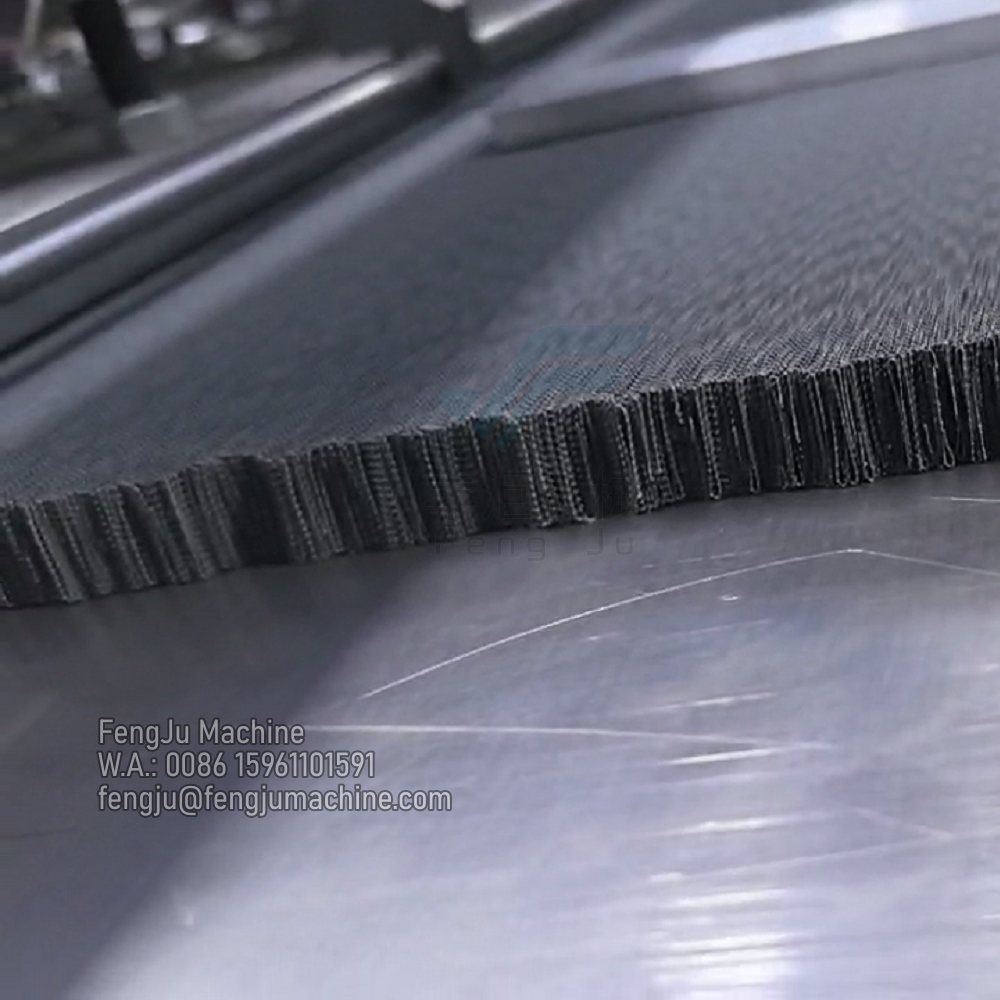

china flymesh pleating machine

The China Flymesh Pleating Machine represents a cutting-edge solution in industrial pleating technology, specifically designed for the precise manufacturing of pleated mesh materials. This advanced machinery combines robust mechanical engineering with sophisticated control systems to create uniform, high-quality pleats in various mesh materials. The machine features an automated feeding system that ensures consistent material handling, coupled with precision-controlled pleating mechanisms that maintain exact fold dimensions throughout the production process. Operating at impressive speeds while maintaining exceptional accuracy, the machine can handle multiple mesh densities and materials, including stainless steel, aluminum, and synthetic meshes. Its intelligent control panel allows operators to easily adjust pleating parameters such as depth, angle, and spacing, ensuring versatility across different production requirements. The machine incorporates advanced tension control systems that prevent material distortion and guarantee uniform pleat formation. Safety features include emergency stop mechanisms, protective guards, and automated fault detection systems. The robust construction ensures long-term reliability and minimal maintenance requirements, while the modular design facilitates easy access for cleaning and parts replacement.