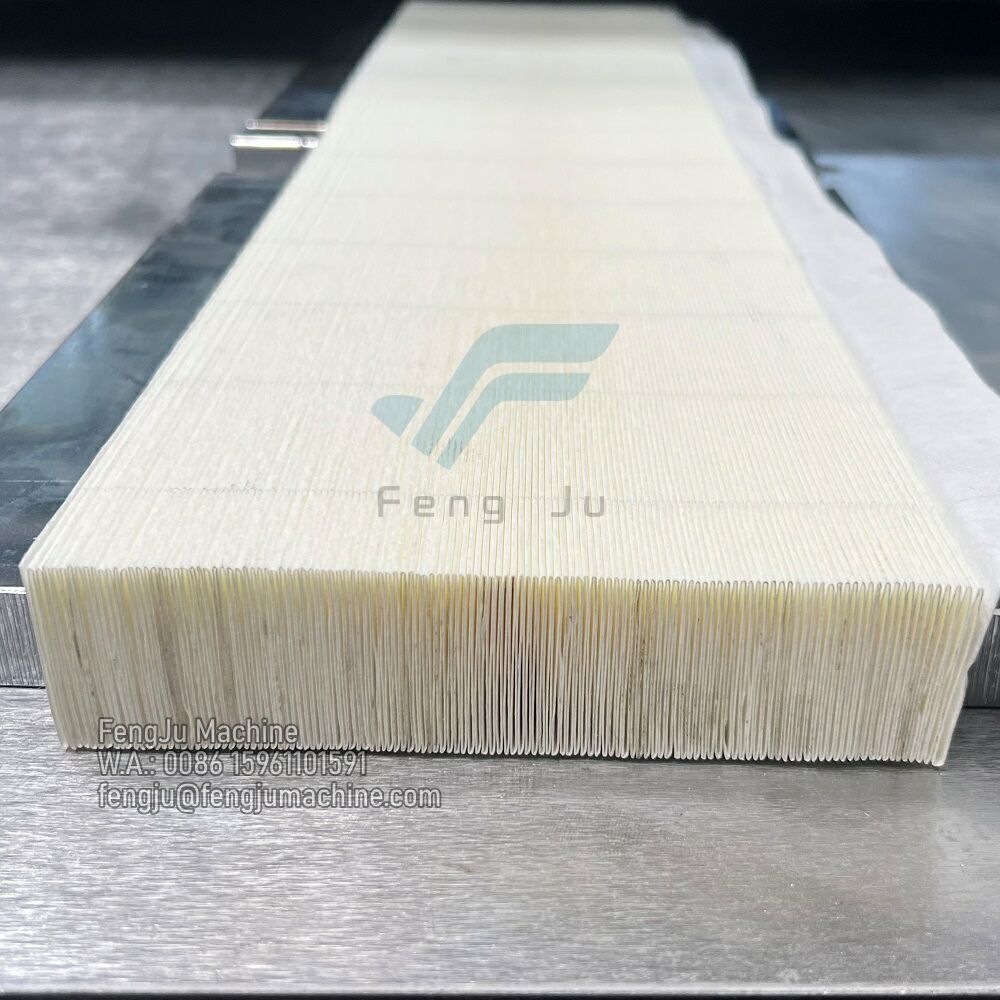

máy làm nếp lọc bụi

Máy gấp nếp lọc bụi đại diện cho một nền tảng then chốt trong công nghệ sản xuất lọc hiện đại, được thiết kế để tạo ra các nếp gấp chính xác trên vật liệu lọc với độ chính xác và độ đồng đều vượt trội. Thiết bị tinh vi này hoạt động thông qua hệ thống đồng bộ gồm cơ chế cấp liệu, lưỡi dao rãnh và các thành phần tạo nếp gấp, phối hợp ăn nhịp để biến vật liệu lọc phẳng thành các tấm lọc có nếp gấp đồng đều. Hệ thống điều khiển tiên tiến của máy cho phép người vận hành điều chỉnh độ sâu, chiều cao và khoảng cách nếp gấp một cách chính xác, đảm bảo hiệu suất lọc tối ưu cho nhiều ứng dụng khác nhau. Thiết bị có thể xử lý nhiều loại vật liệu lọc, bao gồm vật liệu tổng hợp, sợi thủy tinh và các vật liệu composite chuyên biệt, làm cho nó trở nên linh hoạt đáp ứng nhu cầu công nghiệp đa dạng. Hoạt động tự động của máy duy trì hình học nếp gấp ổn định trong suốt quá trình sản xuất, yếu tố then chốt để đảm bảo tiêu chuẩn hiệu suất của bộ lọc. Máy được tích hợp hệ thống giám sát thời gian thực theo dõi các thông số sản xuất và lực căng vật liệu, đảm bảo kiểm soát chất lượng xuyên suốt quy trình sản xuất. Với tốc độ sản xuất có khả năng đáp ứng nhu cầu sản xuất số lượng lớn, máy gấp nếp lọc bụi đại diện cho bước tiến đáng kể trong công nghệ lọc, cho phép các nhà sản xuất tạo ra các bộ lọc chất lượng cao một cách hiệu quả và ổn định.