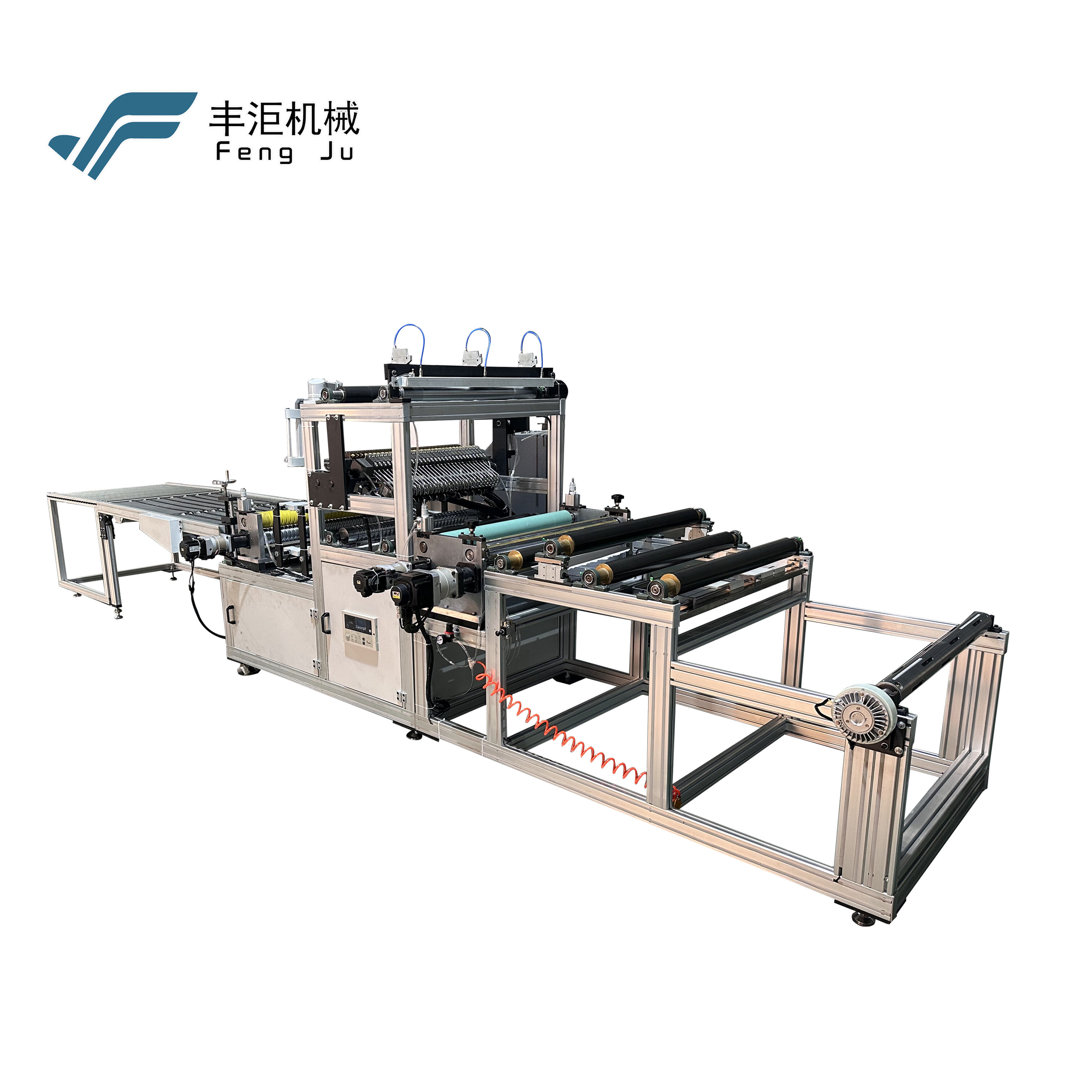

sanoat aralashgich filtrini yig'ish

Sanoat aralash chiqindi filtri burmalash havo so'rish texnologiyasining muhim rivojlanishini ifodalaydi va filtr yuzasini maksimal darajada oshirish bilan bir vaqtda ixcham o'lchamlarni saqlash maqsad qilinadi. Bu murakkab jarayon filtr materialiga tekis parda hosil qilishni o'z ichiga oladi, bu esa berilgan fazoda mavjud bo'lgan umumiy filtr yuzasini sezilarli darajada oshiradi. Burbalash jarayoni har bir parda chuqurligini va oraliqlarini aniq muhandislik asosida optimallashtirish uchun mo'ljallangan bo'lib, havo oqimiga zarar bermasdan changni to'plash samaradorligini maksimal darajaga oshiradi. Ushbu burmalangan filtrlar yuqori harorat va korroziyagil hosil bo'lish kabi qattiq sanoat muhitiga chidamli bo'lgan ilg'or materiallardan tayyorlanadi. Texnologiya turli xil chang zarralarini va ifloslantiruvchilarni boshqarish uchun maxsus ishlab chiqilgan turli xil burmalash namunalari va chuqurligidan foydalanadi. Burbalangan dizayn kengaytirilgan sirt maydoni bo'ylab zarrachalarni ushlab turish imkonini beradi, natijada filtrning foydalanish muddati uzayadi va filtratsiya samaradorligi oshadi. Sanoat sohasida ushbu burmalangan filtrlar havo sifat standartlarini saqlashda, jihozlarni himoya qilishda hamda ish joyidagi xavfsizlikni ta'minlashda muhim rol o'ynaydi. Ushbu texnologiya ishlab chiqarish, farmatsevtika, oziq-ovqat ishlab chiqarish va kimyoviy mahsulotlar ishlab chiqarish kabi sohalarda ayniqsa qimmatli bo'lib, bunda samarali chang nazorati operatsion samaradorlik va me'yoriy talablarga rioya qilish uchun zarur. Burbalash jarayoni shuningdek, namlikka chidamlilik va antimikrob xususiyatlari kabi filtr ishlash ko'rsatkichlarini yaxshilash uchun maxsus qoplamalar va qo'shimcha ishlov berishni ham o'z ichiga oladi.