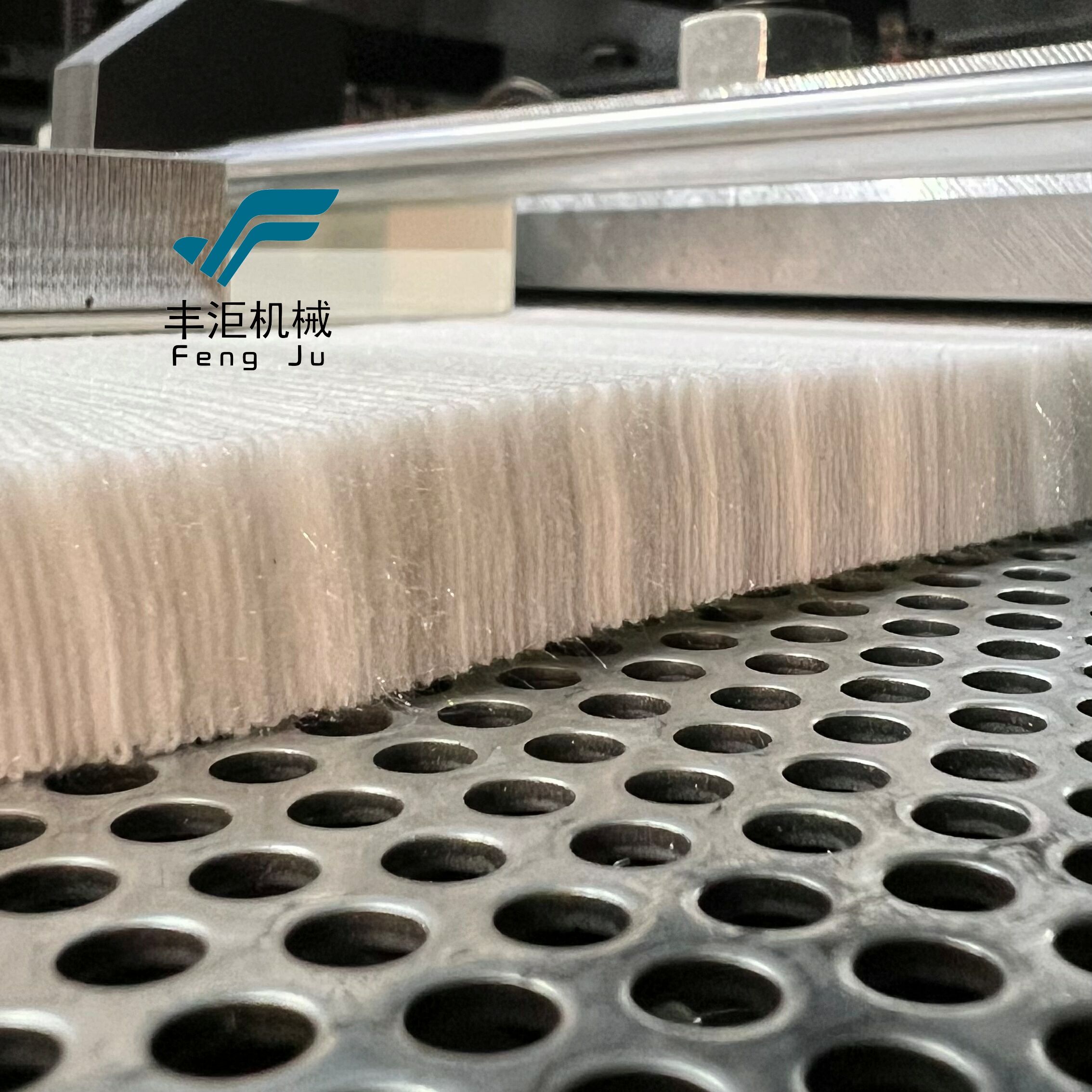

sanoat filtri poldrali qismi

Sanoat filtri plyushechasi tekis filtr materialini akkordeon shaklidagi tuzilmaga aylantiradigan murakkab ishlab chiqarish jarayonidir, bu esa funktsional sirt maydonini sezilarli darajada oshiradi va bir vaqtda ixcham o'lcham saqlanadi. Ushbu ilg'or usul filtrlash materialini bir xil plyushlarga aniq bukib yig'ishni o'z ichiga oladi, natijada filtratsiya samaradorligi oshadi va foydalanish muddati uzaytiriladi. Bu jarayonda sintetik to'qimalar, tsellyuloza hamda aralash materiallar kabi turli xil filtr materiallarini qo'llab-quvvatlaydigan zamonaviy plyush mashinalaridan foydalaniladi. Texnologiyaga filtr elementi orqali bosim pasayishini minimal darajada saqlash uchun aniq chuqurlikni boshqarish hamda plyushlar orasidagi masofani optimallashtirish kiritilgan. Sanoat filtri plyushechasi avtomobil havo filtrlash, HVAC tizimlari, toza xona muhitlari hamda sanoat havo tozalash tizimlari kabi turli sohalarda qo'llaniladi. Plyushli dizayn optimal havo oqimi xususiyatlarini saqlab, zarrachalarni ushlab turish samaradorligini oshirish imkonini beradi. Zamonaviy plyush texnologiyasi ma'lum dasturiy talablarga mos keladigan plyush balandligi, oraliqlari hamda zichligini moslashtirish imkonini beradi va turli ishlash sharoitlarida optimal ishlashni ta'minlaydi. Shu moslashuvchanlik plyushli filtrlarni havo sifatini saqlash, nozik uskunalarni himoya qilish hamda sanoat jarayonlarida me'yoriy talablarga rioya etishda zarur komponentlar qiladi.