uglerod matolari yig'ish mashinasi

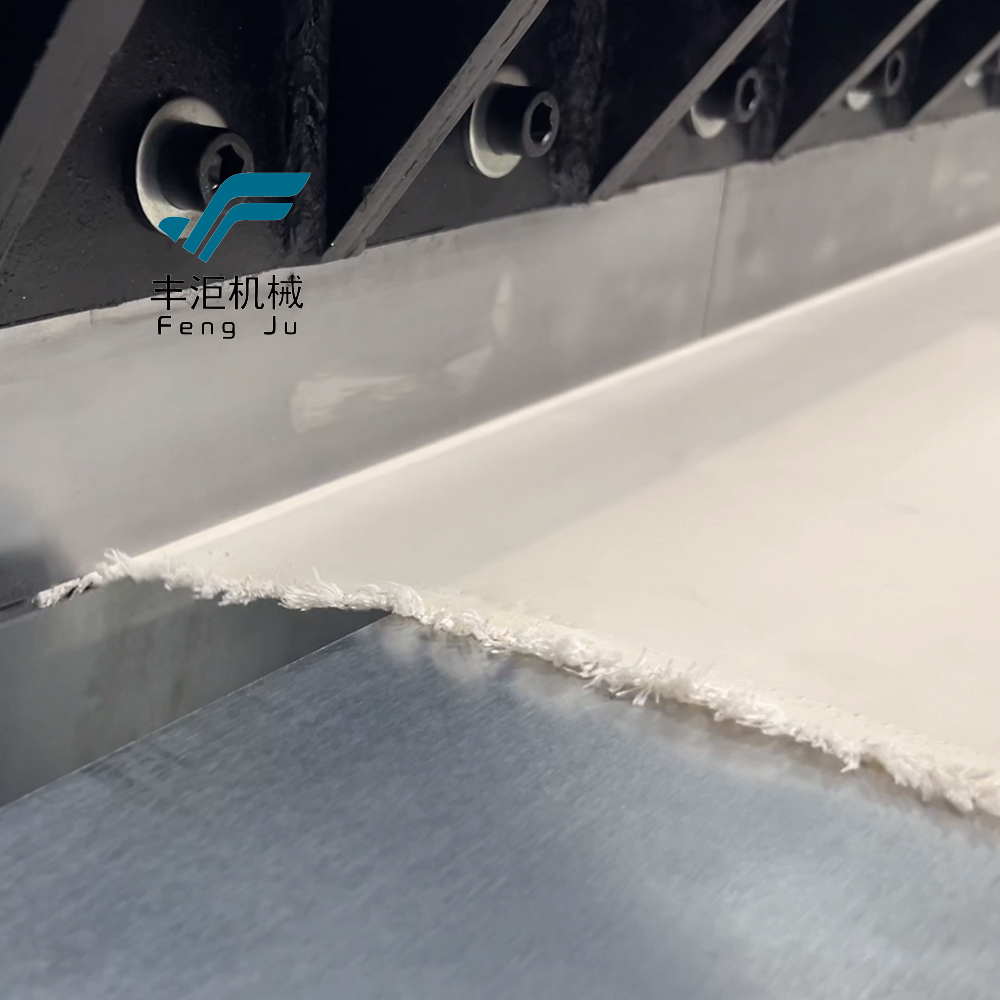

Karbon to'q simobli plyushe mashinasi to'q simob materiallarini aniq poldralar bilan ishlash uchun mo'ljallangan, to'q simob qayta ishlash texnologiyasidagi katta yutug' hisoblanadi. Ushbu murakkab uskuna mexanik aniqlikni raqamli boshqaruv tizimlari bilan birlashtirib, doimiy ravishda yuqori sifatli plyushli karbon to'q simob mahsulotlarini ishlab chiqaradi. Mashinaning ilg'or oziqlantirish mexanizmi nozik karbon tolalarni ehtimollik bilan boshdan kechiradi va butun pleyatsiya jarayonida optimal taranglikni saqlaydi. Dasturiy ta'minotli boshqaruv interfeysi operatorlarga pleyat chuqurligi, oraliqlari va namuna sozlamalarini ajoyib aniqlikda sozlashing imkonini beradi. Tizim pleyatsiya jarayonida haroratni nazorat qilishni ta'minlaydigan maxsus isitish elementlarini o'z ichiga oladi, bu karbon materiallarining strukturaviy buttsizligini saqlash uchun muhim. Mustahkam konstruksiyasi va aniqlik muhandisligi tufayli mashina turli karbon to'q simob kengliklari va qalinligini qo'llab-quvvatlashi mumkin, bu esa uni turli ishlab chiqarish talablari uchun ko'p maqsadli qiladi. Avtomatlashtirilgan operatsion tizim xavfsizlik xususiyatlarini va haqiqiy vaqt rejimida nazorat qilish imkoniyatlarini o'z ichiga oladi, natijada doimiy mahsulot sifatini ta'minlaydi va materiallarning bekor qilinishini minimallashtiradi. Ushbu mashina aviatsiya, avtomobilsozlik va ilg'or kompozit ishlab chiqarish kabi yuqori samaradorlik talab qilinadigan sohalarda ayniqsa qimmatbaho.