තුල් ප්ලිසේ මැළින්

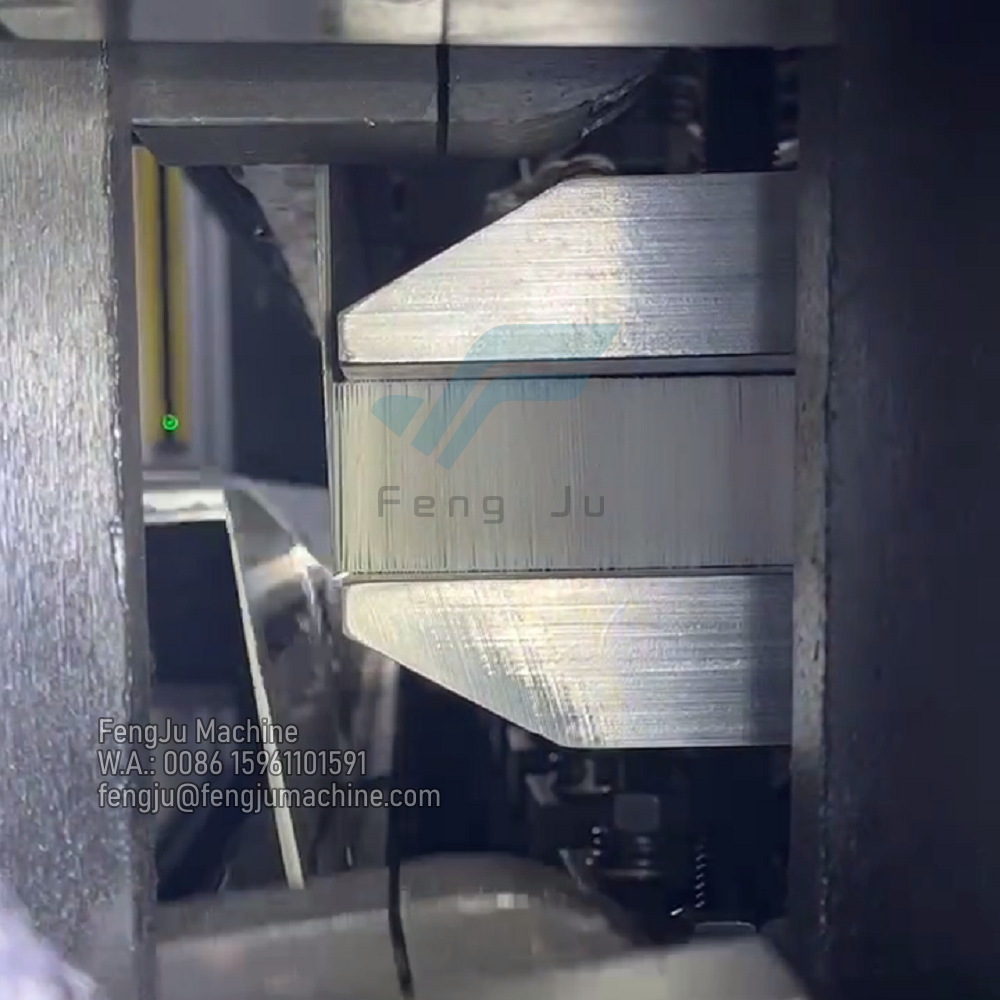

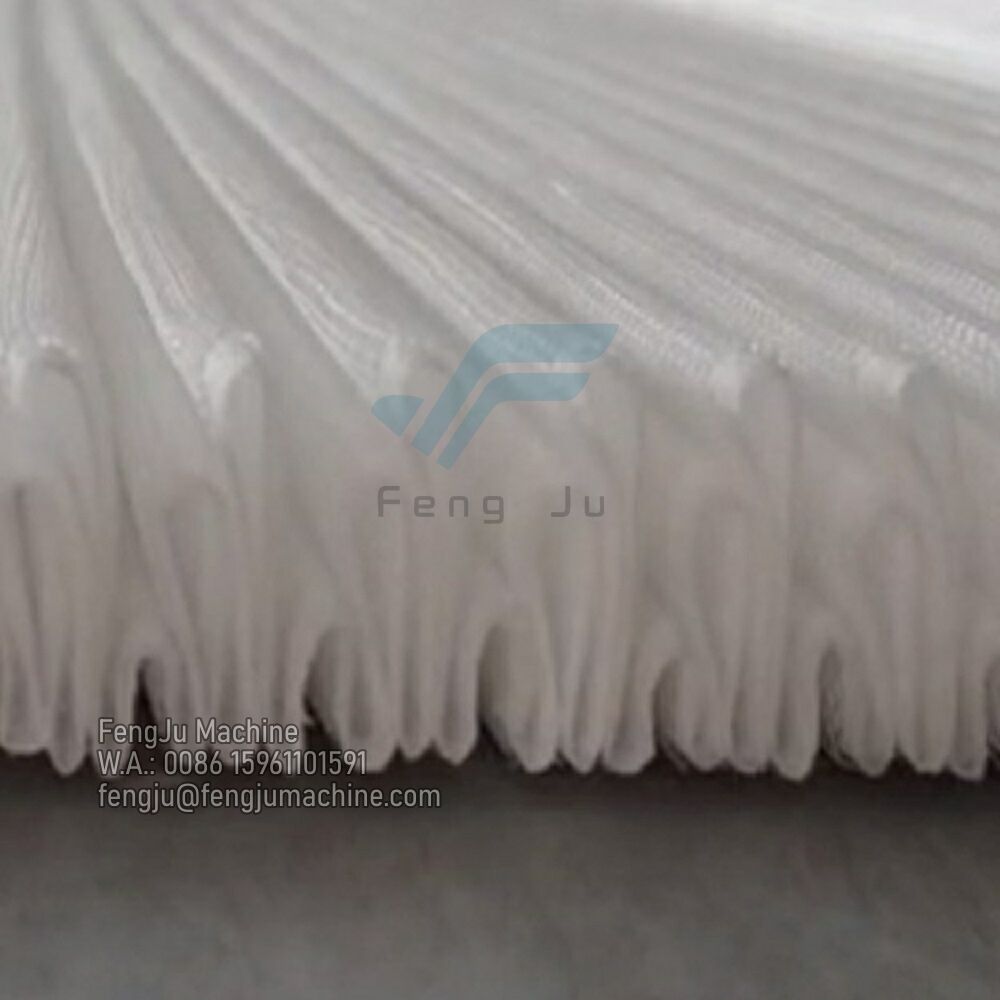

ටුල් ප්ලිසේ යන්ත්රය ටුල් රෙදි වල සංකීර්ණ ප්ලිට් රටා නිර්මාණය කිරීම සඳහා විශේෂයෙන් නිර්මාණය කර ඇති, රෙදි නිෂ්පාදන තාක්ෂණයේ වැදගත් දියුණුවක් නියෝජනය කරයි. මෙම සංකීර්ණ උපකරණය ස්වයංක්රීය සැකසීමේ හැකියාවන් සහිතව නිරවද්ය ඉංජිනේරු ක්රමවේදය ඒකාබද්ධ කර ඇති අතර, සරල ටුල් රෙදි සුවිශේෂී ප්ලිට් රෙදි බවට පරිවර්තනය කරයි. මෙම යන්ත්රය උණුසුම් පුවරු සහ පීඩන යාන්ත්රාංශ වල සැලකිලිමත් පාලනය කරන ලද පද්ධතියක් හරහා ක්රියා කරමින් සැරසිල්ලේ ටුල් රෙදි වලට ස්ථිර, ඒකාකාර ප්ලිට් නිර්මාණය කරයි. එහි අභිරුචිකරණය කළ හැකි ප්ලිට් රටා, විචල්ය වේග සැකසුම් සහ උෂ්ණත්ව පාලන උපාංග ඇතුළත් වන අතර, විවිධ රෙදි බර සහ නිර්මාණ අවශ්යතා සඳහා ගැලපේ. යන්ත්රයේ ස්වයංක්රීය ආහාර දීමේ පද්ධතිය නිරන්තර රෙදි කළමනාකරණය සහතික කරන අතර, දැඩි තන්තු යාන්ත්රාංශ මගින් සැකසීමේදී ද්රව්ය හානිය වැළැක්වේ. විශේෂයෙන්, මෙම යන්ත්රය දුර්වල රිබන් වලින් ආරම්භ කර පළල් රෙදි රෝල දක්වා විවිධ ටුල් පළල් සැකසීමට හැකි වන අතර, විවිධ නිෂ්පාදන අවශ්යතා සඳහා බහුමශක්තිකමක් ලබා දෙයි. ඩිජිටල් පාලන අතුරුමුහුණත මගින් ප්රවේශකයින්ට බහුල ප්ලිට් රටා වැඩසටහන් කර ගබඩා කළ හැකි අතර, විවිධ නිර්මාණ අතර වේගවත් සංක්රාන්තියක් සිදු කළ හැකිය. ආරක්ෂිත ලක්ෂණ අතරට ඔත්තු නතුරු නතුරු නතුරු යාන්ත්රාංශ සහ ද්රව්ය සහ ප්රවේශකයින් දෙපාර්ශවයම ආරක්ෂා කර ගැනීම සඳහා උෂ්ණත්ව නිරීක්ෂණ පද්ධති ඇතුළත් වේ. යන්ත්රයේ කාර්යක්ෂම නිර්මාණය නිරන්තර නිෂ්පාදනය සඳහා ඉඩ සලසන අතර, අතින් සැකසීමේ ක්රම වලට සාපේක්ෂව සැකසීමේ කාලය ඉතා බෙහෙවින් අඩු කරයි, අවසන් නිෂ්පාදනයේ ගුණාත්මකභාවය සහ ඒකාකාරතාව ඉහළ මට්ටමක පවත්වා ගනිමින්.