කැබින් පෙරහර සඳහා පෙලීමේ යන්ත්රය

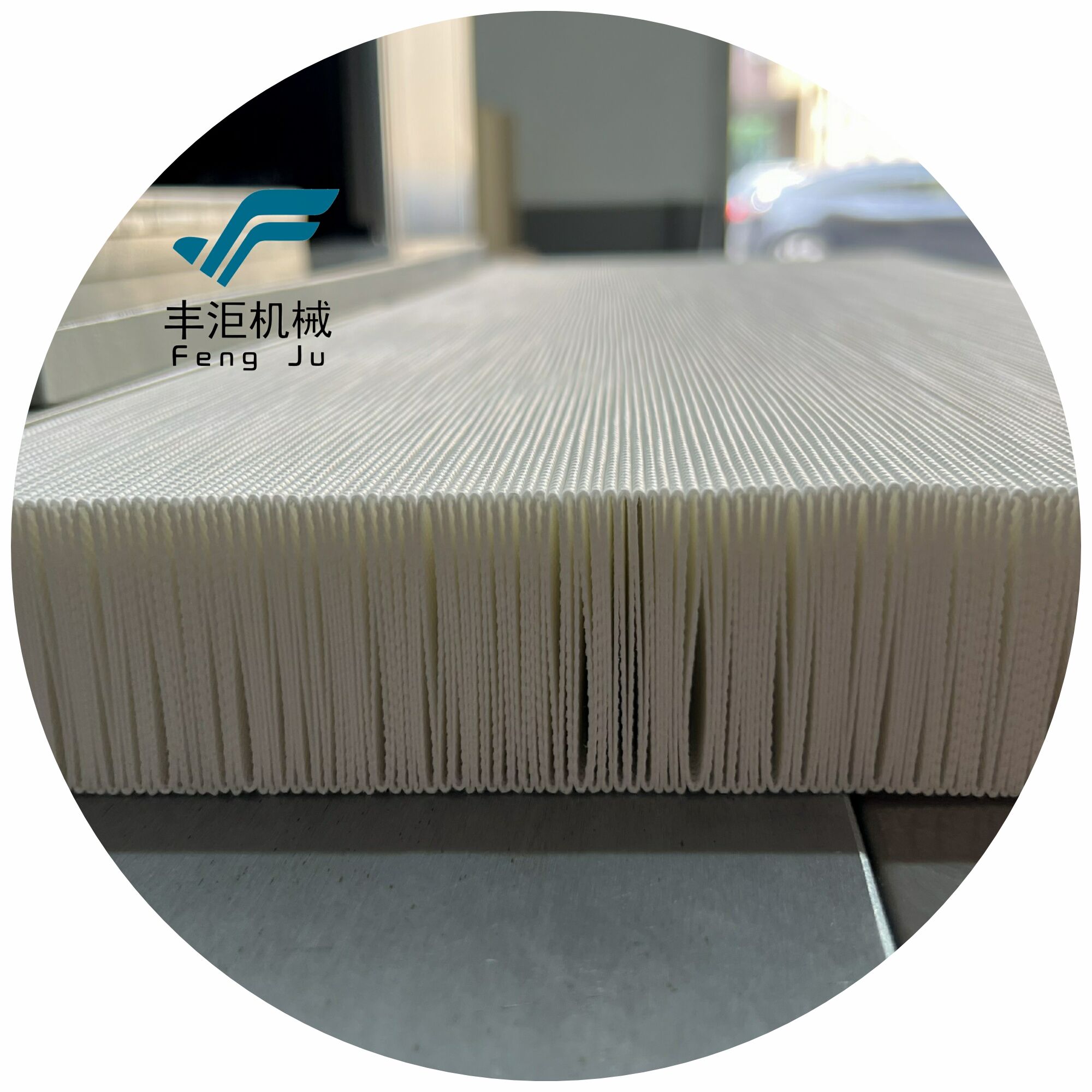

කැබින් පෙල්ට්රේෂන් යන්ත්රය ස්වයං පෙල්ට්රේෂන් නිෂ්පාදනයේ දී අභිරුචි විසඳුමක් නියෝජනය කරයි. මෙම සංකීර්ණ උපකරණය කැබින් වාතය පෙල්ට්රේෂන් සඳහා අත්යවශ්ය වන පරිදි තල පෙල්ට්රේෂන් මාධ්යය නිවැරදිව පෙල්ට්රේෂන් රටාවලට පරිවර්තනය කරයි. යාන්ත්රික හා ප්රවාහිත පද්ධති දෙකේ සංයෝජනයක් හරහා ක්රියා කරමින්, යන්ත්රය විවිධ පෙල්ට්රේෂන් ද්රව්ය සැකසීමේදී නිරන්තර පෙල්ට්රේෂන් උස, ගැඹුර සහ අතර පරතරය පවත්වා ගනී. මෙම පද්ධතියට නිවැරදි පෑ රේඛා නිර්මාණය කරන උසස් ස්කෝරින් යන්ත්රාංග ඇතුළත් වන අතර, ද්රව්යයට හානි නොකර සමාන පෙල්ට්රේෂන් සෑදීම සහතික කරයි. එයට සාමාන්යයෙන් 200mm සිට 1000mm දක්වා පරාසයක විවිධ පෙල්ට්රේෂන් මාධ්ය පළල් සකසා ගැනීමට හැකි ස්වයංක්රීය ආහාර පද්ධති ඇතුළත් වන අතර, 12mm සිට 50mm දක්වා වෙනස් කළ හැකි පෙල්ට්රේෂන් උස ද ඇත. යන්ත්රයේ නිරවද්ය පාලන පද්ධතිය මගින් මිනිත්තුවට මීටර් 80 ක වේගයකින් නිෂ්පාදනය කිරීමට හැකි වන අතරම අතිශය නිරවද්යතාවක් පවත්වා ගනී. උෂ්ණත්වය පාලනය කරන ලද තාප අංග පෙල්ට්රේෂන් ක්රියාවලිය අතරතුර ද්රව්ය තත්ත්වය ප්රමුඛතාවෙන් පවත්වා ගැනීම සහතික කර අභිරුචි සහ දැරිය හැකි පෙල්ට්රේෂන් නිපදවයි. සර්වෝ මෝටර් සහ ඩිජිටල් පාලන ඒකාබද්ධ කිරීම මගින් වේගවත් සකස් කිරීම් සහ නිරන්තර නිෂ්පාදන සැකසුම් සැලසුම් කිරීමට ඉඩ සලසයි. ආලෝකික සංවේදක සහ ඇදීමේ පාලන ඇතුළත් ගුණාත්මකභාවය නිරීක්ෂණ පද්ධති නිරන්තරයෙන් පෙල්ට්රේෂන් සමානාත්මතාව සහ ද්රව්ය සමපාතිතාව තහවුරු කරයි. වාත පෙල්ට්රේෂන් සහ කැටි අල්ලා ගැනීමේ කාර්යක්ෂමතාව සඳහා දැඩි ස්වයං කර්මාන්ත ප්රමිතීන් සපුරාලන ඉහළ කාර්යක්ෂම කැබින් පෙල්ට්රේෂන් නිෂ්පාදනය කිරීමේදී මෙම තාක්ෂණය අමිල වටිනාකමක් දක්වයි.