පීඩිත ජාල තිරය

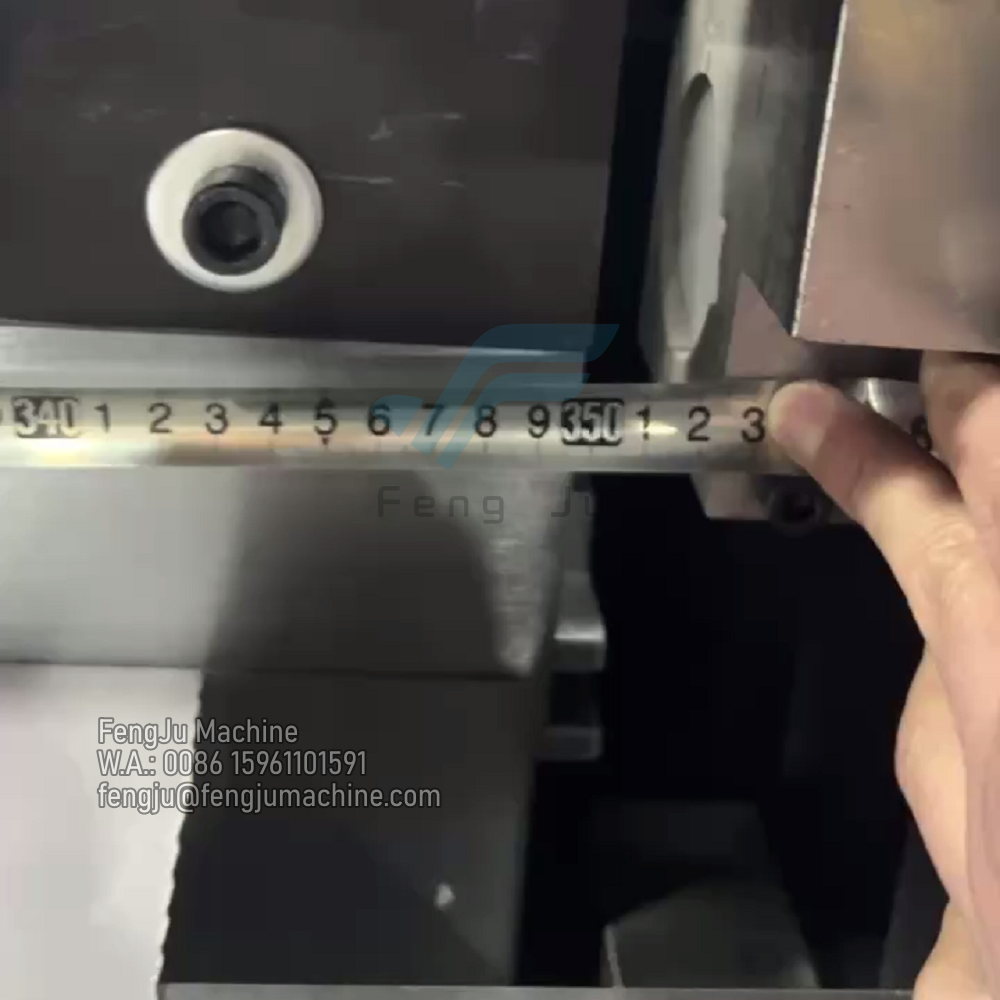

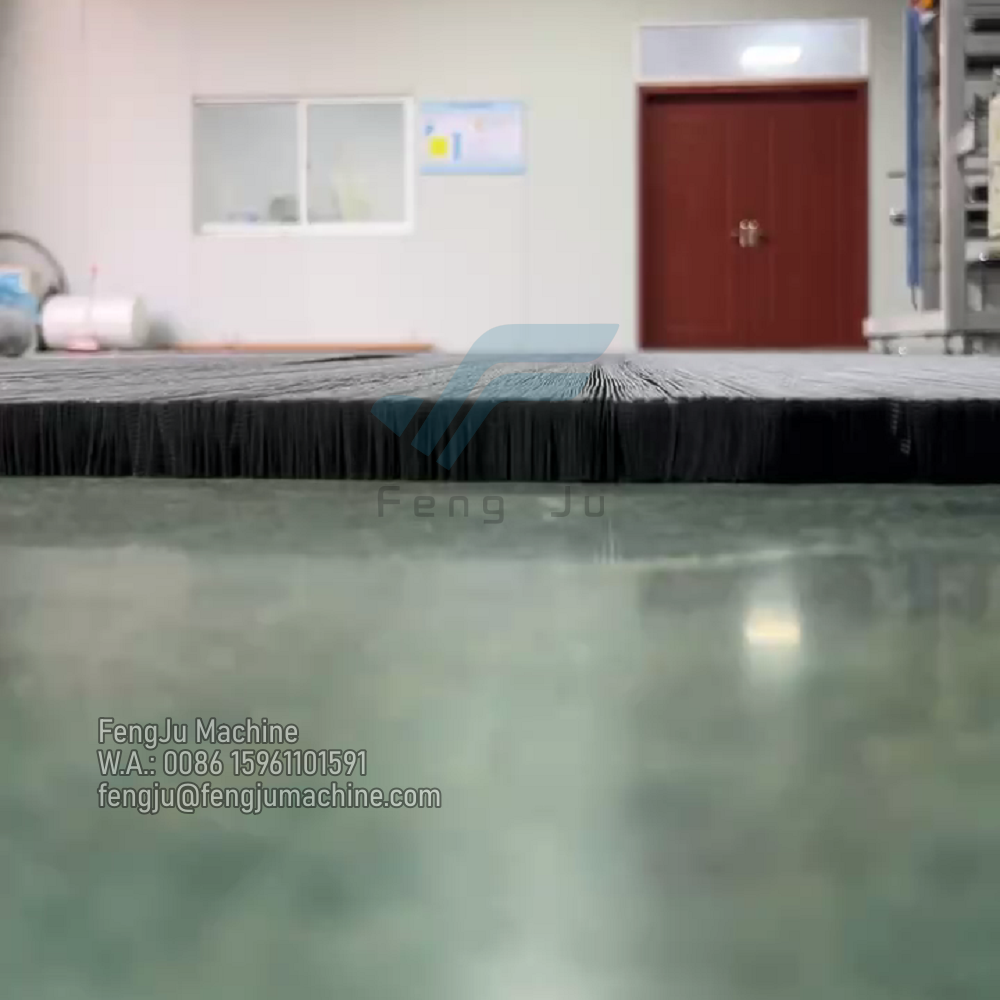

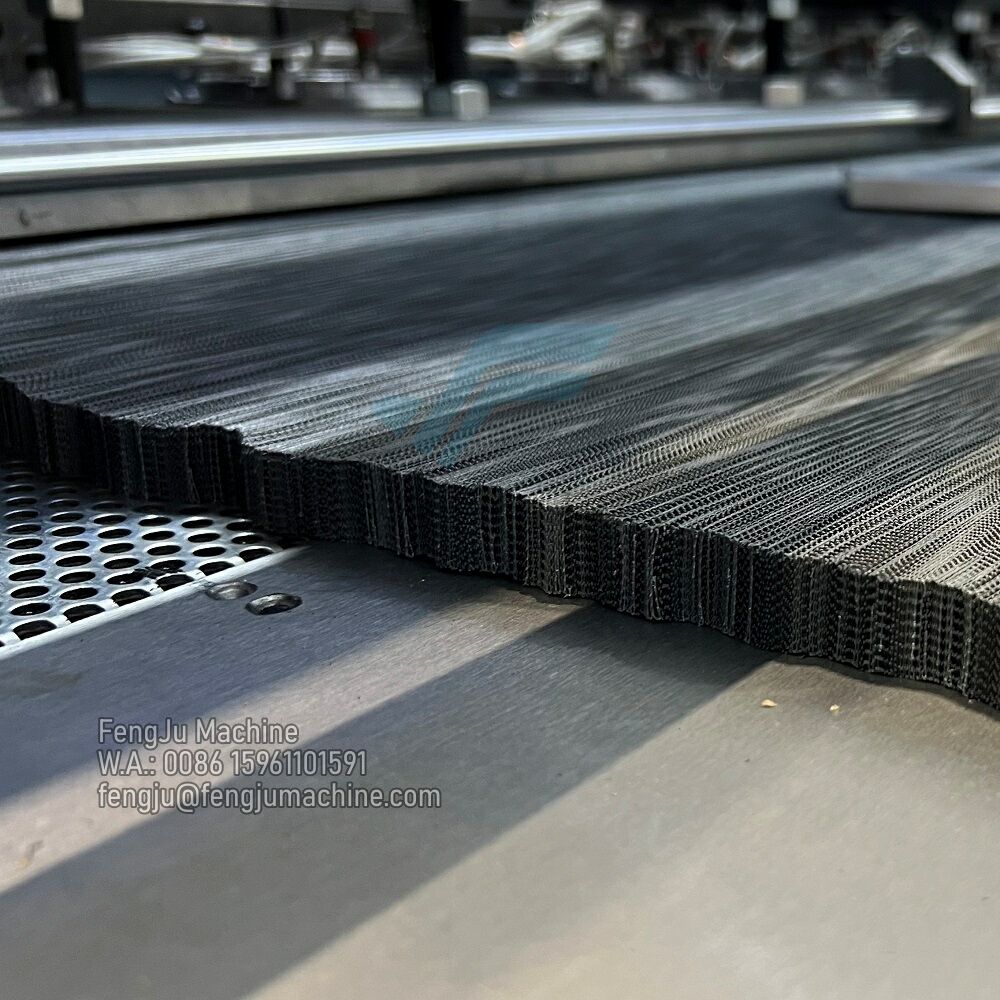

තීරු සහිත ත්රාසිය පෙළ පෙළක් ක්රමවේදය සහ තෝරාගැනීමේ තාක්ෂණයේ වැදගත් දියුණුවක් නියෝජනය කරන අතර, එය දැරිය හැකි ගුණය සහ අතිශයින් හොඳ ක්රියාකාරිත්වය ඒකාබද්ධ කරයි. මෙම නවෝත්පාදන ජාල සැලැස්ම නිවැරදිව ඉංජිනේරු කරන ලද තීරු සහිත ව්යුහයක් ඇති අතර, කුඩා ස්ථාපන පා අඩි රටාවක් රැකෙමින් ඵලදායී පෘෂ්ඨිය වර්ගඵලය ඉතා වැඩි කරයි. තීරු සහිත ව්යුහය සාමාන්ය පැතලි ජාල සැලැස්මට සාපේක්ෂව කැටි අල්ලා ගැනීම සහ ප්රවාහ අලාව වැඩි දියුණු කරයි. දුර්වලතා සහ යාන්ත්රික ආතතියට වැඩි ප්රතිරෝධයක් ලබා දෙන නිසා, උසස් තත්ත්වයේ ද්රව්ය භාවිතා කර නිෂ්පාදනය කරයි - යකඩ රහිත වානේ, සින්තෙටික් පොලිමර් හෝ විශේෂිත ඇලෝය ආදිය. අද්විතීය තීරු සහිත ව්යුහය බහු-තෝරාගැනීමේ ස්ථර නිර්මාණය කරන අතර, ද්රව ප්රවාහ ලක්ෂණ උපරිම තත්ත්වයේ පවත්වා ගනිමින් කැටි ඵලදායීව අල්ලා ගනී. මෙම ත්රාසි වල් පෙළ පෙළක් අංගයක් ඔස්සේ කාර්යක්ෂමතාව උපරිම කර පීඩන පතනය අවම කිරීම සඳහා නිශ්චිත තීරු ගැඹුරු සහ කෝණ සමඟ ඉංජිනේරු කර ඇත. තීරු සහිත ත්රාසි පෙළ පෙළක් විවිධ යෙදුම් සඳහා සුදුසු වන අතර, ජල පෙළ පෙළක්, වායු සෝදනය, රසායනික සැකසීම සහ කර්මාන්ත වෙළුම් ක්රියාවලි ඇතුළත් වේ. සමාන තීරු අතර ඇති දුර සහ නිවැරදි ජාල අව opening යන් ඇතුළත් සැලැස්ම පූර්ණ ත්රාසි පෘෂ්ඨිය පුරා ස්ථාවර ක්රියාකාරිත්වය සහ විශ්වසනීය පෙළ පෙළක් ප්රතිඵල සහතික කරයි. තවද, තීරු වලින් ලැබෙන වැඩි පෘෂ්ඨිය වර්ගඵලය පෙළ පෙළක් කිරීමට පෙර දූවිලි දරා ගැනීමේ හැකියාව වැඩි කිරීම හරහා පෙළ පෙළක් කිරීමේ සේවා කාලය දීර්ඝ කරයි.