drapery pleater යන්ත්රය

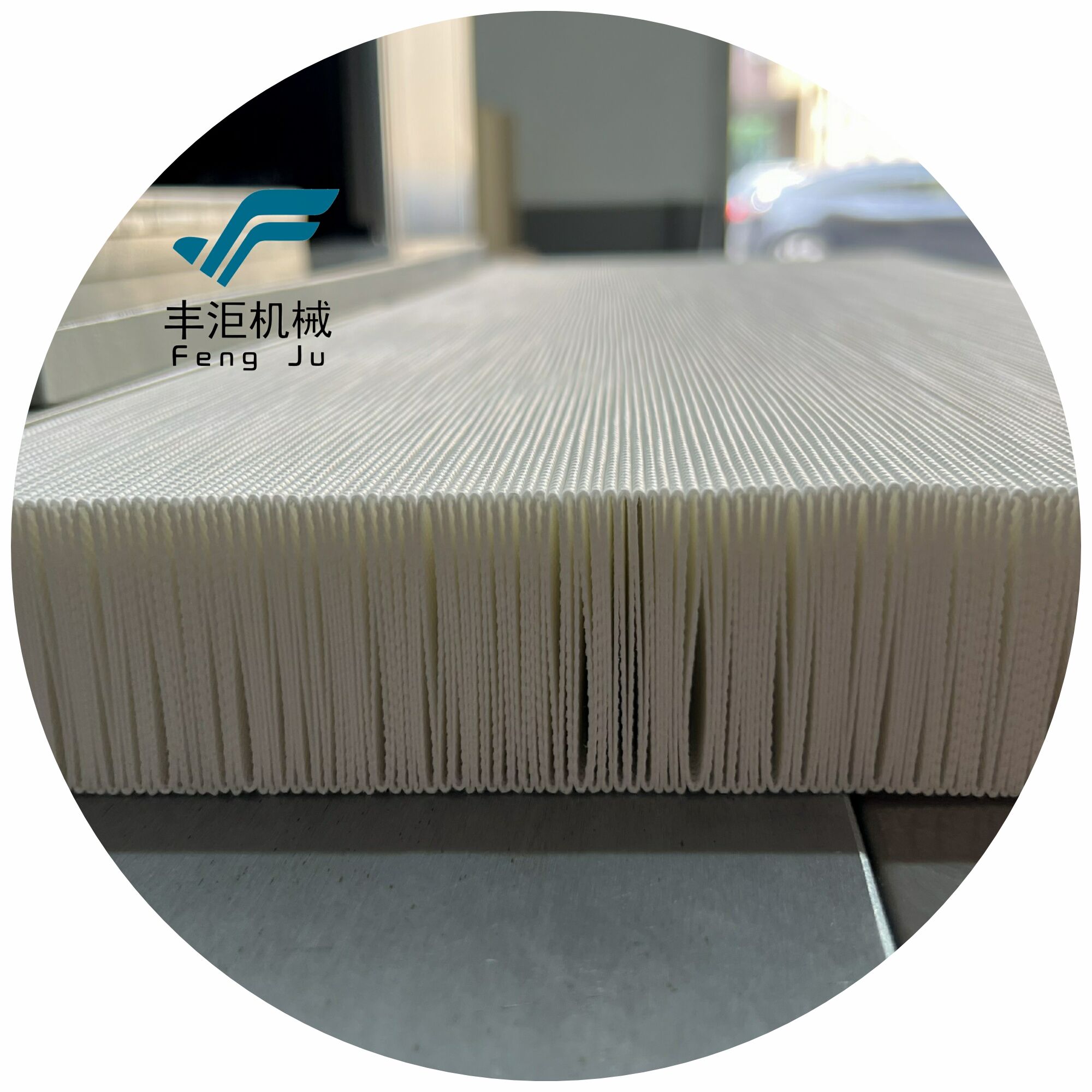

ඩ්රැපරි ප්ලීටර් යන්ත්රය යනු රෙදි ද්රව්ය වල නිවැරදිව හා ඒකාකාර ප්ලීට් (සැකිලි) නිර්මාණය කිරීම සඳහා නිර්මාණය කර ඇති නවෝත්පාදන රෙදි සැකසුම් උපකරණයකි. මෙම උසස් යන්ත්රය යාන්ත්රික නිරවද්යතාව සහ අභිරුචිකරණය කළ හැකි සැකසීම් ඒකාබද්ධ කර ගනිමින් විවිධ රෙදි වර්ග හා බර සඳහා ඒකාකාර ප්ලීට් රටා නිර්මාණය කරයි. මෙම යන්ත්රයට ප්ලීට් ගැඹුර සඳහා සකස් කළ හැකි පාලන, ස්වයංක්රීය රෙදි ආහාර යාන්ත්රාංශ, හා ප්ලීට් සඳහා උපරිම ප්රතිඵල සහතික කර ගැනීම සඳහා නිවැරදි උෂ්ණත්ව පාලන පද්ධති ඇත. එහි ප්රධාන කාර්යයන් අතරට සම්මත පින්ච් ප්ලීට්, බොක්ස් ප්ලීට් සහ කාට්රිජ් ප්ලීට් වෘත්තීය නිරවද්යතාවෙන් නිර්මාණය කිරීම ඇතුළත් වේ. තාක්ෂණික ලක්ෂණ අතරට නිවැරදි මිනුම් සඳහා ඩිජිටල් පාලන පුවරු, ස්වයංක්රීය අතරු ගණක, සහ ප්ලීට් ස්ථාවර කිරීමට උෂ්ණත්ව සැකසීමේ හැකියාවන් ඇතුළත් වේ. මෙම යන්ත්රය බහුල රෙදි පළල් සකසා ගත හැකි අතර සැහැල්ලු හා බර ද්රව්ය දෙකම අඩංගු වන බැවින් විවිධ ඩ්රැපරි ව්යාපෘති සඳහා බහුමාධ්ය වේ. යෙදුම් ගෘහ ඩ්රැපරි නිෂ්පාදනයේ සිට වාණිජ කවුළු සැකසීම් නිෂ්පාදනය, ආගන්තුක කර්මාන්තයේ අලංකරණ, සහ අභිරුචි අභ්යන්තර නිර්මාණ ව්යාපෘති දක්වා පරාස වේ. මෙම පද්ධතියේ කාර්යක්ෂමතාව නිෂ්පාදන කාලය සැලකිය යුතු ලෙස අඩු කරන අතර විශාල පරාසයක ක්රියාකාරකම් තුළ නිරන්තර ගුණාත්මකභාවය පවත්වා ගනී.