ເຄື່ອງຕັດ HEPA ໂດຍບໍ່ມີເຄື່ອງກັ່ນຕອງ

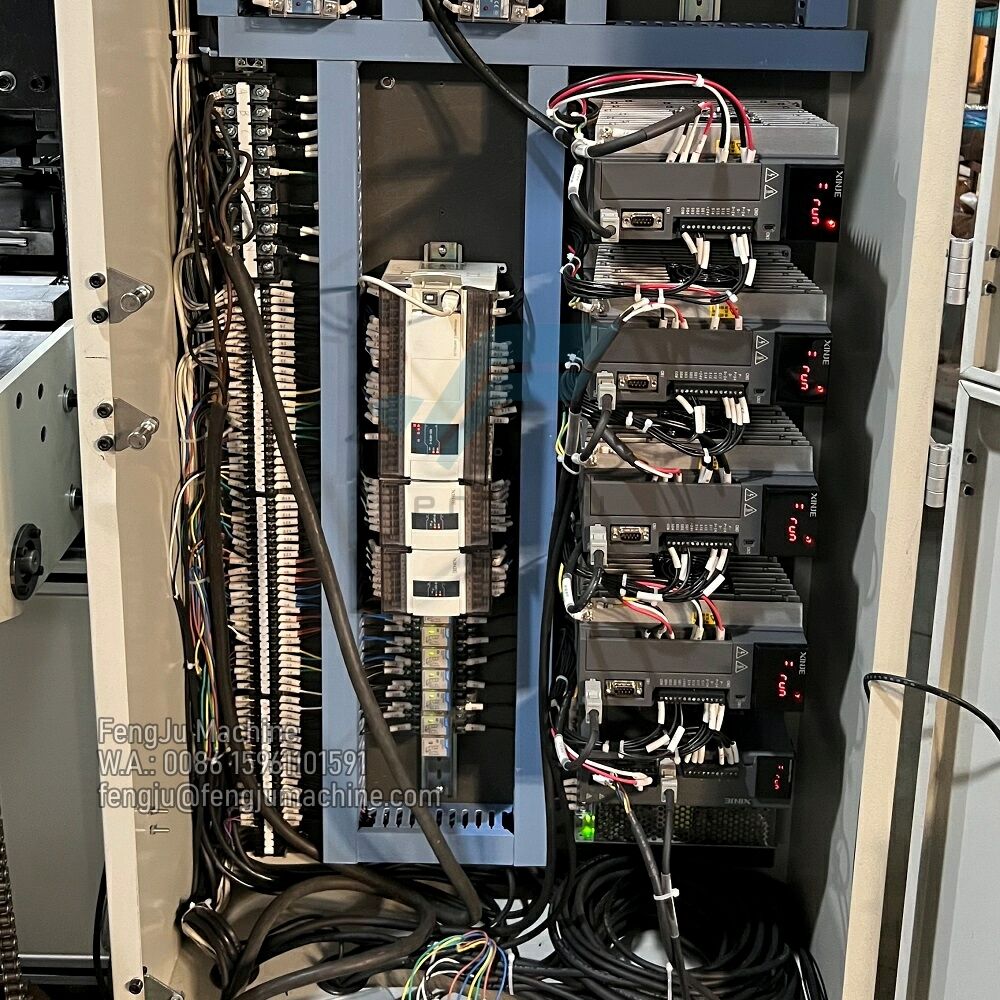

ເຄື່ອງພັບເຄືອງກອງ HEPA ໂດຍບໍ່ມີແຜ່ນກັ້ນເປັນການພັດທະນາທີ່ສຳຄັນໃນດ້ານເຕັກໂນໂລຊີການຜະລິດເຄື່ອງກອງອາກາດ. ອຸປະກອນທີ່ທັນສະໄໝນີ້ຖືກອອກແບບມາເພື່ອຜະລິດພັບເຄືອງກອງອາກາດປະສິດທິພາບສູງ (HEPA) ຢ່າງຖືກຕ້ອງ ແລະ ມີປະສິດທິພາບ ໂດຍບໍ່ຈຳເປັນຕ້ອງໃຊ້ລະບົບແຜ່ນກັ້ນແບບດັ້ງເດີມ. ເຄື່ອງນີ້ໃຊ້ລະບົບຄວບຄຸມມໍເຕີເຊີໂວ (servo motor) ທີ່ທັນສະໄໝເພື່ອຮັບປະກັນການສ້າງພັບທີ່ຖືກຕ້ອງ ແລະ ມີຊ່ອງຫວ່າງທີ່ສອດຄ່ອງກັນ ເຊິ່ງເຮັດໃຫ້ເຄື່ອງກອງມີປະສິດທິພາບດີຂຶ້ນ. ການດຳເນີນງານອັດຕະໂນມັດປະກອບມີຫຼາຍຂັ້ນຕອນ ລວມທັງການສະຫຼາຍວັດສະດຸ, ການຂູດ, ການພັບ ແລະ ການເກັບກຳ ໂດຍທັງໝົດນີ້ຖືກເຊື່ອມຕໍ່ເຂົ້າກັນຢ່າງລຽບງ່າຍໃນແຖວການຜະລິດດຽວ. ເຄື່ອງດັ່ງກ່າວສາມາດຈັດການກັບວັດສະດຸເຄືອງກອງທີ່ແຕກຕ່າງກັນ ລວມທັງໄຍແກ້ວ, ໄຍສັງເຄາະ ແລະ ວັດສະດຸປະສົມ ໂດຍມີຄວາມສູງຂອງພັບທີ່ສາມາດປັບໄດ້ຕັ້ງແຕ່ 20mm ຫາ 100mm. ດ້ວຍຄວາມໄວໃນການດຳເນີນງານສູງສຸດເຖິງ 15 ແມັດຕໍ່ນາທີ ເຄື່ອງນີ້ຮັກສາຄວາມຖືກຕ້ອງສູງໃນຮູບຮ່າງ ແລະ ຊ່ອງຫວ່າງຂອງພັບ. ການບໍ່ມີແຜ່ນກັ້ນຊ່ວຍໃຫ້ການບຳລຸງຮັກສາງ່າຍຂຶ້ນ ແລະ ຫຼຸດຜ່ອນຈຸດທີ່ອາດເກີດຂໍ້ຜິດພາດ ໃນຂະນະດຽວກັນກໍຊ່ວຍໃຫ້ມີຄວາມຍືດຫຍຸ່ນຫຼາຍຂຶ້ນໃນການອອກແບບພັບ. ລະບົບດັ່ງກ່າວມີຄວາມສາມາດໃນການຕິດຕາມກວດກາແບບທັນທີເພື່ອຄວບຄຸມຄຸນນະພາບ ແລະ ຕິດຕາມປະສິດທິພາບໃນການຜະລິດ ເຮັດໃຫ້ເໝາະສຳລັບການດຳເນີນງານຜະລິດໃນຂະໜາດໃຫຍ່ ແລະ ສິ່ງອຳນວຍຄຳນວນຜະລິດເຄື່ອງກອງທີ່ຊຳນິຊຳນານ.