플리스스 기계

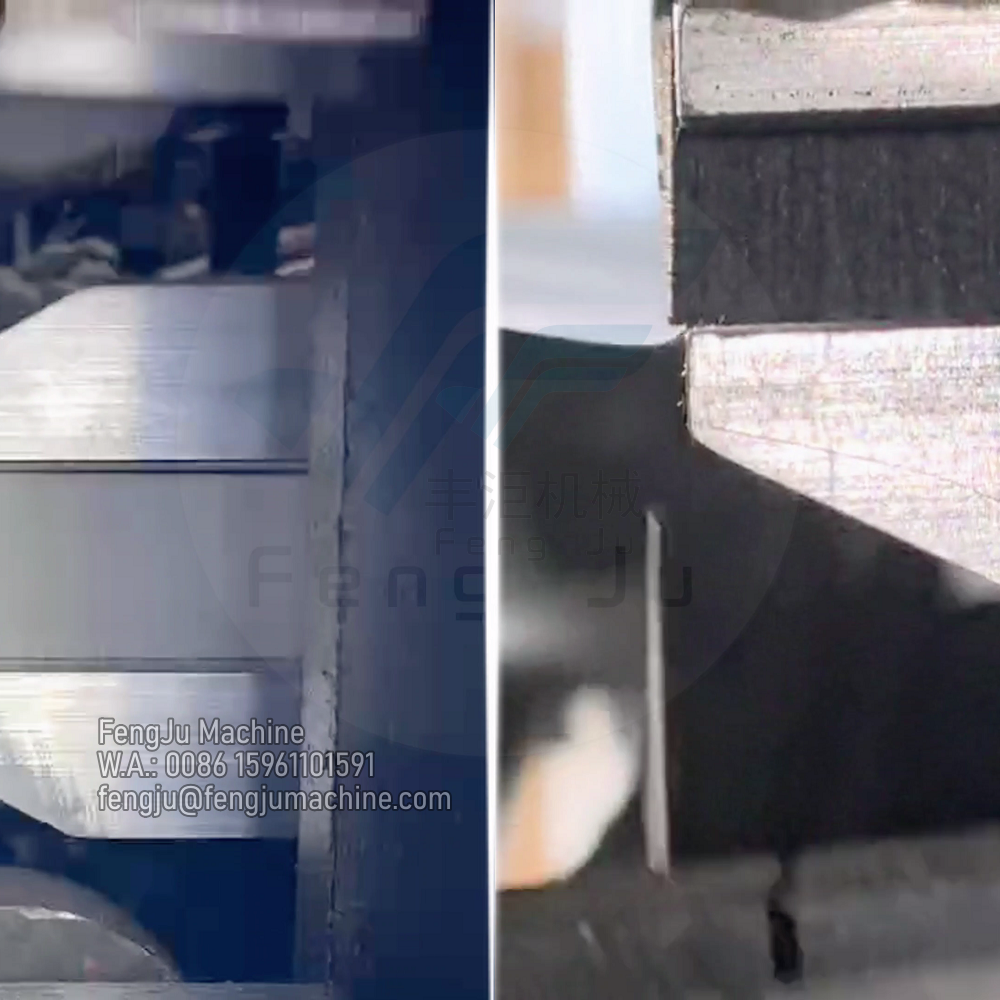

플리세 기계는 직물 가공 기술 분야의 최첨단 발전을 대표하며, 직물 소재에 정밀하고 균일한 주름 패턴을 만드는 것을 목적으로 설계되었습니다. 이 고도화된 장비는 열가공, 기계적 압력 및 정밀 제어를 결합하여 산업 규모에서 일관된 주름 처리된 섬유를 생산합니다. 이 기계의 핵심 기능은 얇은 합성섬유부터 두꺼운 천연 소재까지 다양한 종류의 직물에 영구적이고 날카로운 주름을 형성하는 능력에 있습니다. 자동화 시스템에는 온도 조절이 가능한 판, 압력을 조정할 수 있는 장치, 원하는 주름 치수를 정확히 재현할 수 있도록 프로그래밍 가능한 패턴 제어 장치가 포함되어 있습니다. 또한 고급 디지털 인터페이스를 통해 작업자는 다양한 직물 유형과 주름 패턴에 따라 특정 매개변수를 입력할 수 있어 다양한 제조 요구에 매우 유연하게 대응할 수 있습니다. 산업용 플리세 기계는 대량의 직물을 효율적으로 처리하면서도 전체 소재에 걸쳐 일관된 주름 품질을 유지할 수 있는 연속 공급 시스템을 갖추고 있습니다. 이 기계들은 비상 정지 장치, 온도 모니터링 시스템, 자동 전원 차단 장치와 같은 안전 기능을 통합하여 작업자와 소재 모두를 보호합니다. 해당 기술은 패션 제조, 가정용 섬유 제품, 산업용 직물 가공 분야에 폭넓게 적용되며 현대 섬유 생산 시설에서 필수적인 도구로 자리 잡고 있습니다.