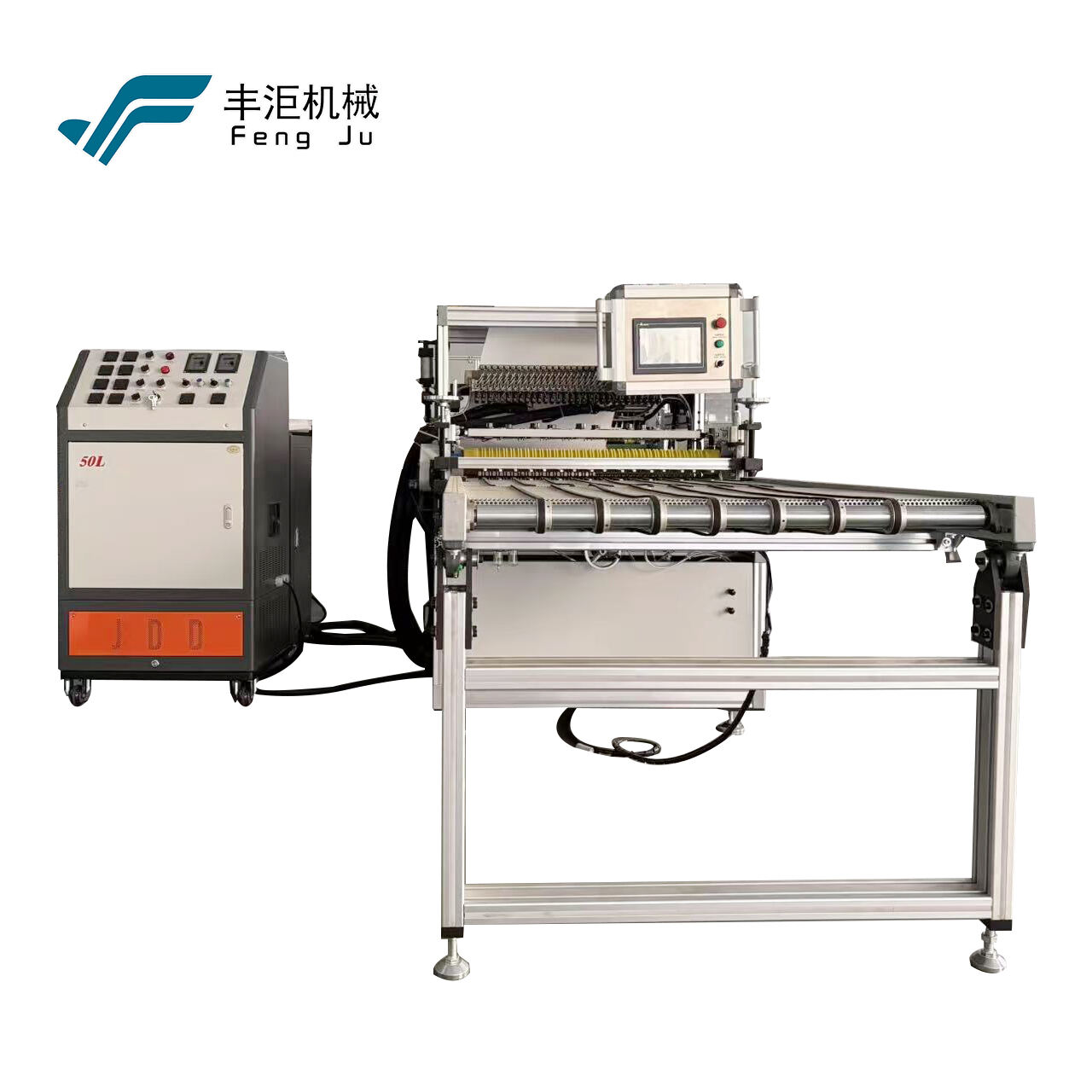

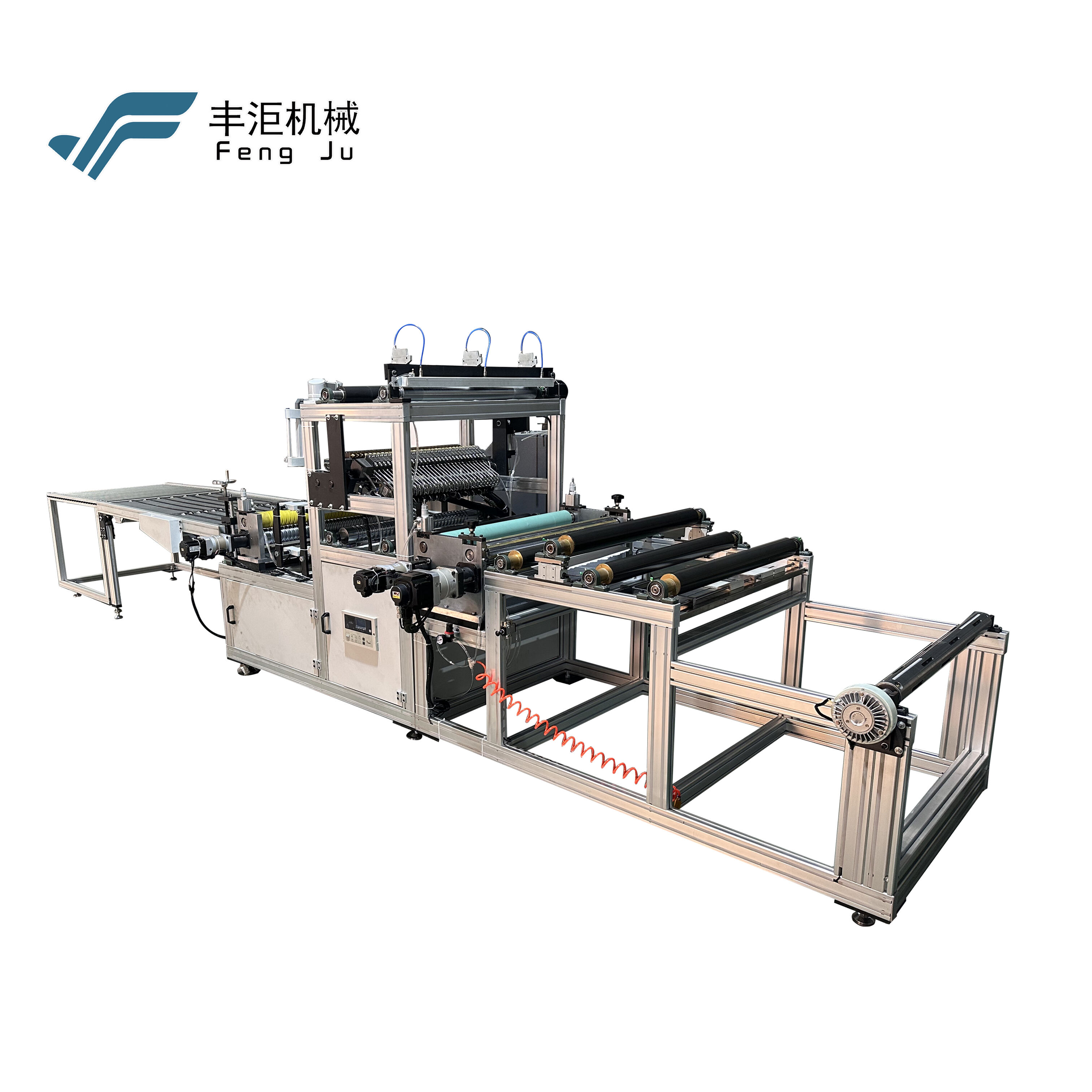

piegatura filtro hepa

La piegatura dei filtri HEPA rappresenta un progresso fondamentale nella tecnologia di filtrazione dell'aria, fungendo da elemento centrale dei moderni sistemi di purificazione dell'aria. Questo processo sofisticato prevede la piegatura precisa di materiali filtranti specializzati in una serie di pieghe uniformi, aumentando notevolmente la superficie disponibile per la cattura delle particelle pur mantenendo un fattore di forma compatto. Il processo di piegatura crea numerosi canali attraverso i quali l'aria deve passare, intrappolando efficacemente particelle piccole fino a 0,3 micron con un'efficienza del 99,97%. L'ingegneria alla base della piegatura dei filtri HEPA richiede un'attenta considerazione della profondità, dello spaziamento e della densità delle pieghe per ottimizzare il flusso d'aria massimizzando al contempo la capacità di filtrazione. Questi filtri piegati sono realizzati con diversi materiali, tra cui fibra di vetro, fibre sintetiche o materiali compositi, ciascuno selezionato per applicazioni specifiche. La progettazione a pieghe consente una maggiore capacità di ritenzione della polvere, una vita utile del filtro più lunga e una riduzione della caduta di pressione attraverso il materiale filtrante. Nelle applicazioni industriali, la piegatura dei filtri HEPA è essenziale per camere bianche, strutture mediche e produzione farmaceutica. Per uso residenziale, questi filtri si distinguono nel rimuovere allergeni, polvere, forfora animale e altri contaminanti aerodispersi, contribuendo a un miglioramento della qualità dell'aria interna.