stroj na plisované závěsy

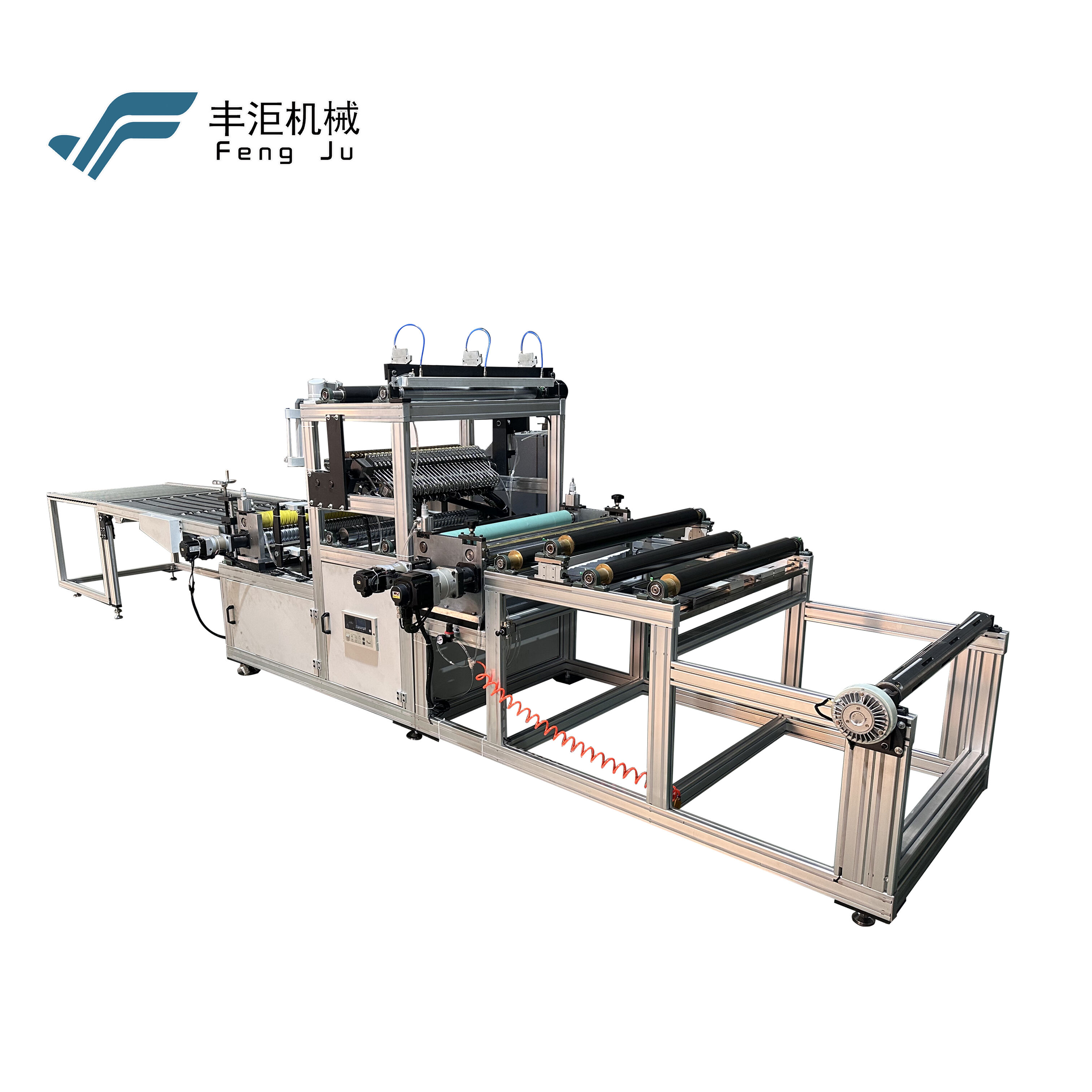

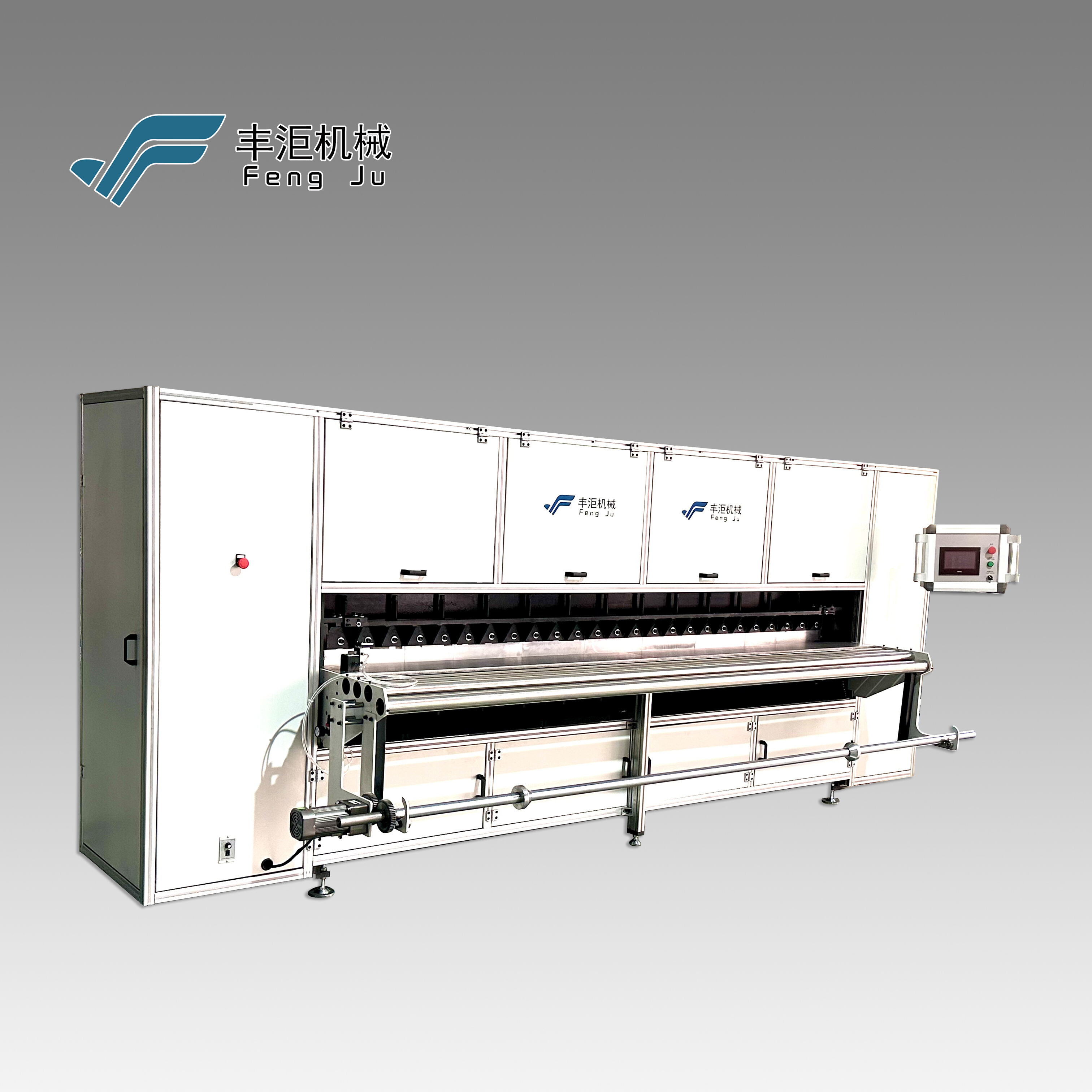

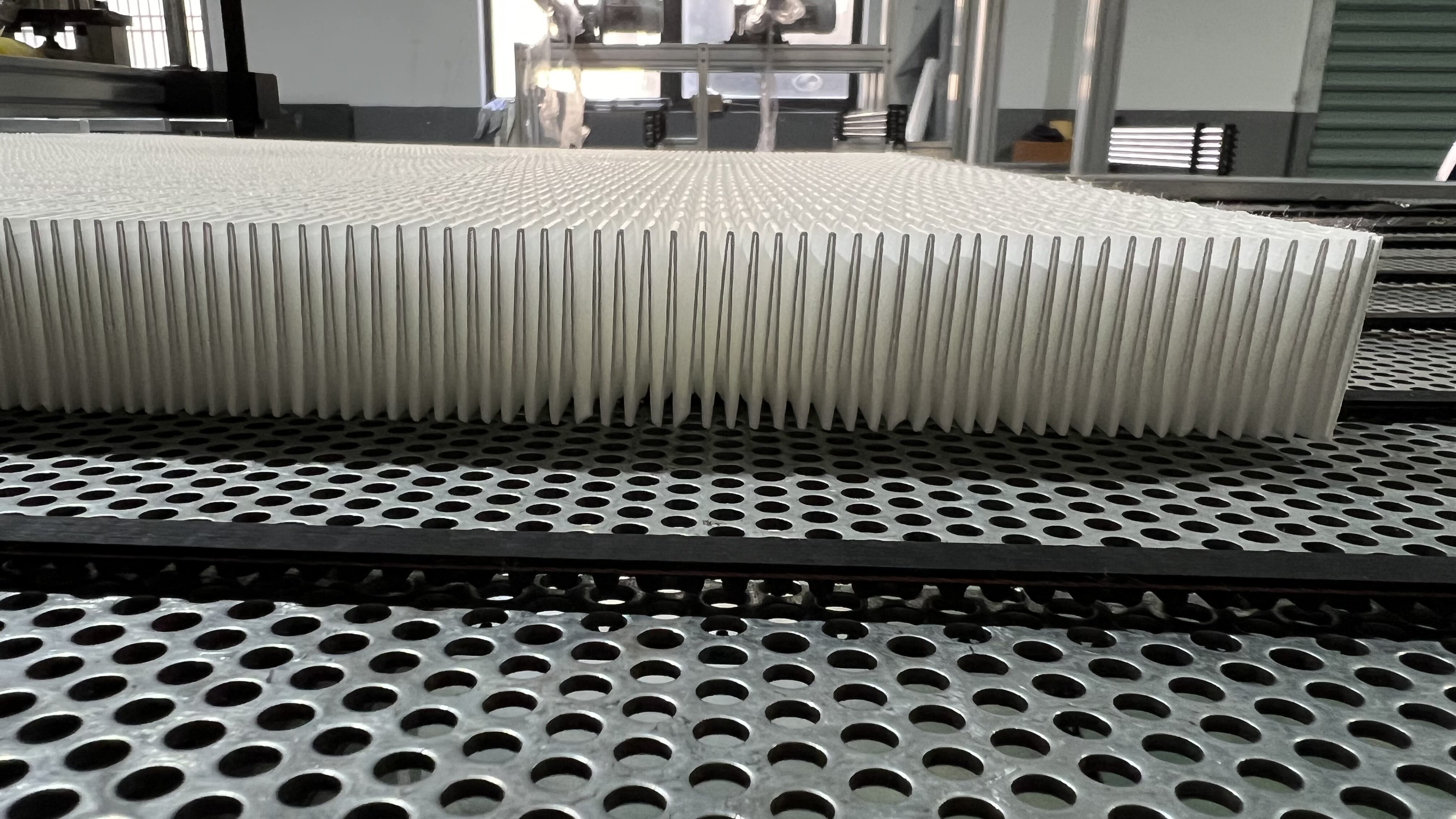

Stroj plise perde představuje špičkový pokrok v technologii výroby záclon, který je speciálně navržen pro výrobu přesných plisovaných žaluzií a clon. Tento sofistikovaný stroj automatizuje složitý proces tvorby rovnoměrných plis v textilních materiálech a zajišťuje tak konzistentní kvalitu a přesnost rozměrů. Stroj je vybaven pokročilými možnostmi tepelného nastavení, které trvale fixují plisy do různých typů tkanin, od lehkých polyesterů po těžší dekorativní materiály. Jeho počítačový řídicí systém umožňuje obsluze programovat konkrétní velikost plis, jejich vzdálenost a vzory, čímž nabízí širokou škálu návrhových možností. Stroj je vybaven robustním podavačem, který zvládá šířku tkaniny až 3 metry, což ho činí vhodným jak pro bytové, tak komerční aplikace. Systémy řízení teploty udržují optimální úroveň tepla pro různé složení tkanin, zatímco integrované měřicí a stříhací komponenty zajišťují přesné délky. Stroj plise perde výrazně zkracuje výrobní čas ve srovnání s manuálními metodami plisování, a to při zachování vynikajících standardů kvality. Jeho automatický provoz vyžaduje minimální zásah operátora a je vybaven bezpečnostními mechanismy, které chrání během výrobního procesu jak operátora, tak materiál.