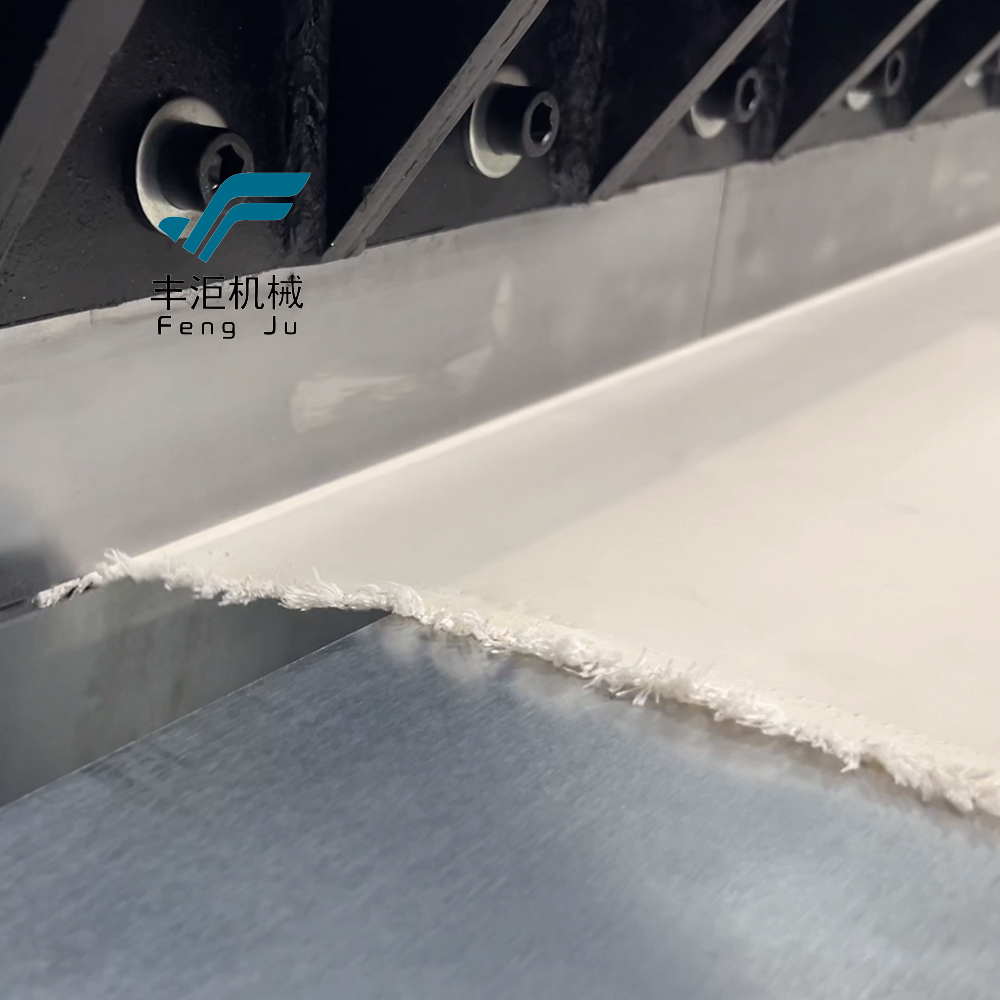

stroj na skládání textilie

Stroj na plisování látek je sofistikované zařízení navržené tak, aby vytvářelo rovnoměrné a přesné záhyby v různých textilních materiálech. Tato inovativní technika kombinuje mechanickou přesnost s pokročilými řídicími systémy, které mění ploché tkaniny na krásně plisované vzory. Stroj pracuje tak, že podává tkaninu skrz sérii vyhřívaných desek nebo válců, které vytvářejí trvalé záhyby v předem určených intervalech. Je vybaven nastavitelnými parametry pro hloubku záhybu, jejich vzdálenost a složitost vzoru, což umožňuje výrobcům dosáhnout rozmanitých stylů – od jednoduchých akordeonových záhybů až po složité architektonické návrhy. Technologie zahrnuje systémy řízení teploty, které zajišťují optimální rozložení tepla, což je klíčové pro vytvoření trvalých záhybů u různých typů tkanin. Moderní stroje na plisování jsou vybaveny digitálními rozhraními, která umožňují přesné nastavení parametrů a programování vzorů, čímž zaručují reprodukovatelné výsledky i při velkých sériích výroby. Tyto stroje zvládnou širokou škálu hmotností a složení tkanin, od lehkých chiffonů až po těžší tapetové materiály, a jsou tak univerzálním nástrojem pro různé průmyslové odvětví, jako je móda, dekorace interiérů a průmyslové aplikace. Automatizovaný proces výrazně snižuje manuální práci a zároveň zachovává konzistentní kvalitu po celou dobu výrobní série.