Establishing an efficient air filter production line requires careful planning, strategic equipment selection, and systematic implementation of manufacturing processes. Modern industrial facilities demand high-quality filtration systems to maintain clean air standards, making the development of streamlined production capabilities essential for meeting market demand. The setup process involves multiple considerations including facility layout, machinery specifications, quality control systems, and operational workflows that ensure consistent output and optimal performance.

Essential Equipment Selection for Manufacturing Setup

Primary Production Machinery Requirements

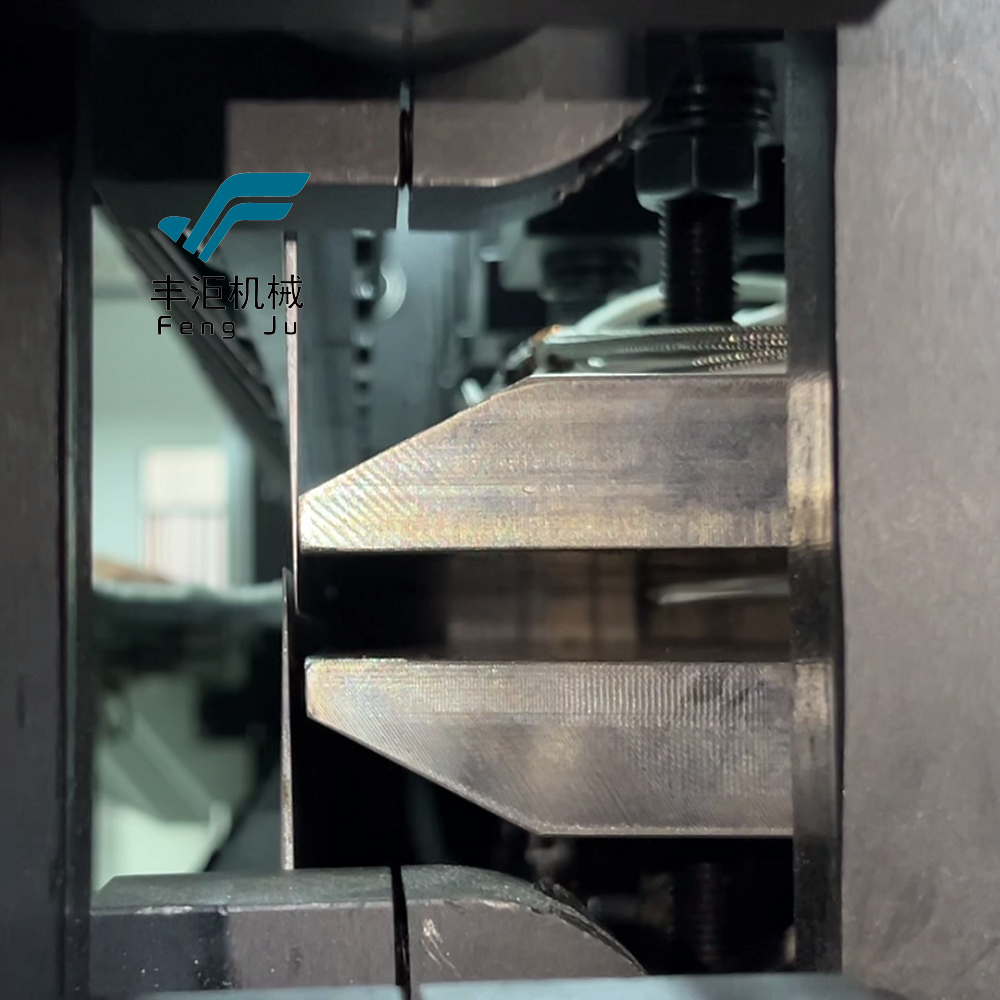

The foundation of any successful manufacturing operation begins with selecting appropriate machinery that matches production volume requirements and quality specifications. Core equipment typically includes filter media cutting machines, pleating equipment, frame assembly stations, and adhesive application systems. Each component plays a critical role in maintaining consistent product quality while maximizing throughput efficiency. Modern automated systems offer precision control over material handling, reducing waste and improving overall productivity metrics.

Filter media cutting equipment must provide accurate dimensional control to ensure proper fit within housing assemblies. High-speed rotary cutters or laser cutting systems deliver precise cuts while minimizing material waste. The selection between mechanical and laser cutting depends on production volume, material types, and required edge quality. Advanced cutting systems incorporate automated feeding mechanisms that reduce manual handling and improve worker safety protocols.

Quality Control and Testing Equipment

Implementing comprehensive quality assurance requires specialized testing equipment to verify filter performance characteristics including airflow resistance, particle retention efficiency, and structural integrity. Testing stations should include differential pressure measurement systems, particle counting equipment, and leak detection apparatus. Regular calibration of testing equipment ensures accurate performance verification throughout the manufacturing process. Investment in automated testing systems reduces labor costs while providing consistent quality validation.

Environmental testing chambers allow manufacturers to verify filter performance under various operating conditions including temperature extremes, humidity variations, and chemical exposure scenarios. These controlled testing environments ensure products meet industry specifications and customer requirements before shipment. Documentation systems integrated with testing equipment provide traceability and compliance with regulatory standards.

Facility Layout and Workflow Optimization

Production Floor Planning Strategies

Efficient facility layout maximizes material flow while minimizing handling time and reducing contamination risks. The optimal design incorporates linear production sequences that eliminate backtracking and reduce work-in-progress inventory accumulation. Clean room requirements for certain filter types necessitate controlled environments with appropriate ventilation systems and contamination prevention protocols. Strategic placement of quality control checkpoints throughout the production flow enables early detection of defects and reduces rework costs.

Storage areas for raw materials should be positioned near initial processing stations to minimize transportation distances and handling requirements. Finished goods storage requires climate-controlled environments to preserve product integrity during warehousing periods. Maintenance areas should be accessible to production equipment while maintaining separation from manufacturing zones to prevent contamination during service activities.

Material Handling and Inventory Management

Automated material handling systems reduce labor costs and improve consistency in component delivery throughout the production process. Conveyor systems, automated guided vehicles, and robotic handling equipment streamline material movement while reducing potential damage during transportation. Inventory management systems integrated with production scheduling software ensure adequate material availability while minimizing carrying costs and storage space requirements.

Just-in-time delivery protocols coordinate supplier shipments with production schedules to reduce inventory investment and storage requirements. Advanced planning systems analyze historical demand patterns and production capacity to optimize material ordering and delivery timing. Integration with supplier systems enables real-time visibility into material availability and delivery schedules.

Process Control and Automation Implementation

Manufacturing Execution Systems

Modern air filter production line operations rely on sophisticated manufacturing execution systems that coordinate all aspects of the production process. These systems integrate machine control, quality monitoring, inventory tracking, and production scheduling into unified platforms that provide real-time visibility into operations. Automated data collection eliminates manual record keeping while ensuring accurate tracking of production metrics and quality parameters.

Production scheduling modules optimize machine utilization while balancing customer delivery requirements and inventory levels. Advanced algorithms consider machine capabilities, material availability, and quality requirements when generating production schedules. Real-time adjustments accommodate equipment maintenance needs and urgent customer requests without disrupting overall production efficiency.

Quality Management Integration

Integrated quality management systems automatically collect performance data from testing equipment and production machinery to identify trends and potential issues before they impact product quality. Statistical process control algorithms analyze measurement data to detect process variations and trigger corrective actions when necessary. Automated documentation systems maintain complete records of quality test results and corrective actions for regulatory compliance and customer audits.

Traceability systems track individual products through each production stage, enabling rapid identification of affected inventory in the event of quality issues. Barcode or RFID tracking systems automatically record processing information and link quality test results to specific product batches. This comprehensive tracking capability supports warranty claims processing and regulatory investigations while demonstrating commitment to quality management.

Workforce Training and Safety Protocols

Operator Skill Development Programs

Successful production line operation requires comprehensive training programs that develop operator skills in equipment operation, quality control procedures, and safety protocols. Structured training curricula should include hands-on equipment operation, troubleshooting procedures, and quality inspection techniques. Regular skill assessments ensure operators maintain proficiency while identifying areas requiring additional training or refresher courses.

Cross-training programs develop operator flexibility by teaching multiple production skills, enabling efficient workforce deployment during peak demand periods or equipment maintenance activities. Advanced operators can serve as mentors for new employees while providing technical support during complex production challenges. Investment in operator development improves retention rates while building internal expertise for continuous improvement initiatives.

Safety Management and Compliance

Comprehensive safety programs protect workers while ensuring compliance with occupational health regulations and industry standards. Regular safety training sessions cover equipment operation procedures, emergency response protocols, and hazard recognition techniques. Safety management systems track incident reports, near-miss events, and corrective actions to identify improvement opportunities and prevent future accidents.

Personal protective equipment programs ensure workers have appropriate protection for their specific job functions while maintaining comfort and productivity. Regular equipment inspection and replacement schedules maintain protection effectiveness while complying with regulatory requirements. Safety performance metrics integrated with production reporting systems provide visibility into safety trends and program effectiveness.

Maintenance and Continuous Improvement

Preventive Maintenance Strategies

Systematic preventive maintenance programs maximize equipment availability while minimizing unexpected downtime and repair costs. Maintenance scheduling systems coordinate routine service activities with production schedules to minimize disruption while ensuring adequate equipment care. Predictive maintenance technologies including vibration monitoring, thermal imaging, and oil analysis enable early detection of potential equipment problems before they cause production interruptions.

Maintenance technician training programs develop skills in equipment troubleshooting, repair procedures, and predictive maintenance techniques. Well-trained maintenance teams can quickly diagnose problems and implement effective solutions while maintaining safety standards. Investment in maintenance training reduces equipment downtime while extending machinery life and improving overall production efficiency.

Performance Optimization Initiatives

Continuous improvement programs systematically identify opportunities for enhancing production efficiency, quality performance, and cost reduction. Regular performance reviews analyze production metrics, quality data, and cost information to identify improvement priorities and develop implementation plans. Employee suggestion programs encourage operator input for process improvements while building engagement in optimization efforts.

Lean manufacturing principles eliminate waste while streamlining production processes and improving overall efficiency. Value stream mapping identifies non-value-added activities and opportunities for process simplification. Implementation of lean tools including 5S workplace organization, standardized work procedures, and error-proofing techniques creates disciplined production environments that support consistent quality and efficiency improvements.

FAQ

What is the typical timeline for setting up a complete air filter production line

The timeline for establishing a complete production facility typically ranges from 12 to 18 months depending on facility size, equipment complexity, and regulatory requirements. Initial planning and design phases require 3-4 months, followed by 6-8 months for equipment procurement and installation. The remaining time involves system commissioning, operator training, and production qualification activities before full-scale operation begins.

How much space is required for an efficient air filter manufacturing facility

Space requirements vary significantly based on production volume and product types, but typical facilities require 15,000 to 50,000 square feet for complete operations. This includes production areas, raw material storage, finished goods warehousing, quality control laboratories, and administrative offices. Clean room requirements for certain filter types may increase space needs due to specialized ventilation and contamination control systems.

What are the key quality standards that air filter production must meet

Air filter manufacturing must comply with various industry standards including ASHRAE 52.2 for filtration efficiency testing, UL 900 for safety requirements, and ISO 9001 for quality management systems. Additional standards may apply depending on specific applications such as HEPA filters for cleanroom environments or automotive filters for vehicle applications. Regular third-party testing and certification ensure compliance with applicable standards.

What is the expected return on investment for air filter production equipment

Return on investment for production equipment typically ranges from 15% to 25% annually, depending on market conditions, production efficiency, and product mix. Factors influencing ROI include equipment utilization rates, labor productivity, quality performance, and market pricing dynamics. Careful analysis of market demand, competitive positioning, and operational capabilities helps optimize investment decisions and maximize returns.

Table of Contents

- Essential Equipment Selection for Manufacturing Setup

- Facility Layout and Workflow Optimization

- Process Control and Automation Implementation

- Workforce Training and Safety Protocols

- Maintenance and Continuous Improvement

-

FAQ

- What is the typical timeline for setting up a complete air filter production line

- How much space is required for an efficient air filter manufacturing facility

- What are the key quality standards that air filter production must meet

- What is the expected return on investment for air filter production equipment