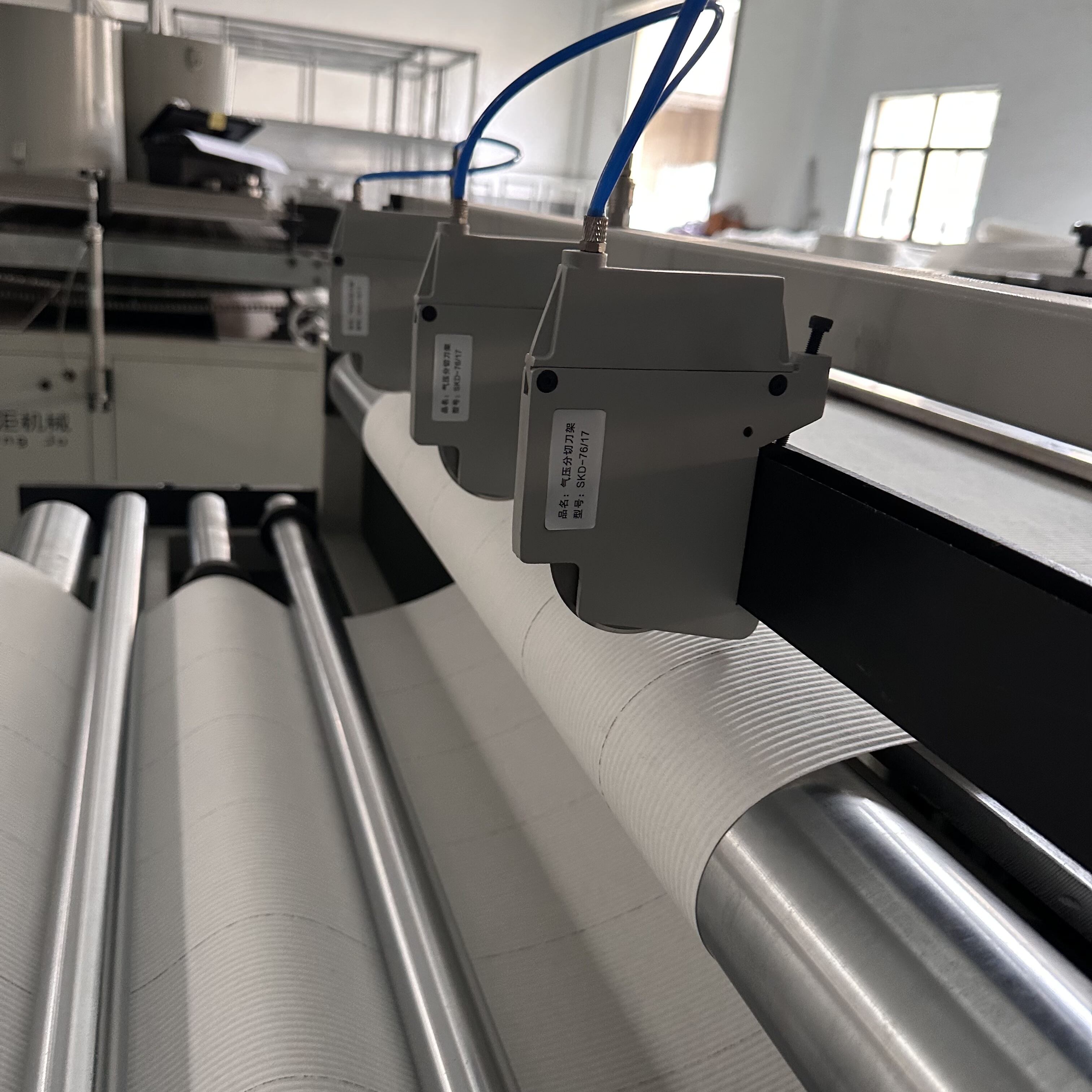

filter making machine

The filter making machine represents a cutting-edge solution in industrial filtration technology, designed to manufacture high-quality filters with precision and efficiency. This sophisticated equipment combines advanced automation with precise control systems to produce various types of filters, including air, oil, and hydraulic filters. The machine features a comprehensive production line that handles everything from raw material processing to final assembly. Its state-of-the-art control panel allows operators to adjust parameters such as pleating depth, media tension, and cutting specifications with exceptional accuracy. The system incorporates multiple stations including media unwinding, pleating, frame assembly, and end-cap attachment, all working in synchronized harmony. With production speeds capable of reaching up to 30 meters per minute, this machine significantly enhances manufacturing efficiency while maintaining consistent quality standards. The filter making machine employs advanced sensing technology to monitor production parameters in real-time, ensuring each filter meets exact specifications. Its versatile design accommodates different filter media types and sizes, making it suitable for various industrial applications. The machine's modular construction allows for easy maintenance and future upgrades, while its robust build quality ensures long-term reliability in demanding industrial environments.