máy gấp rèm servo

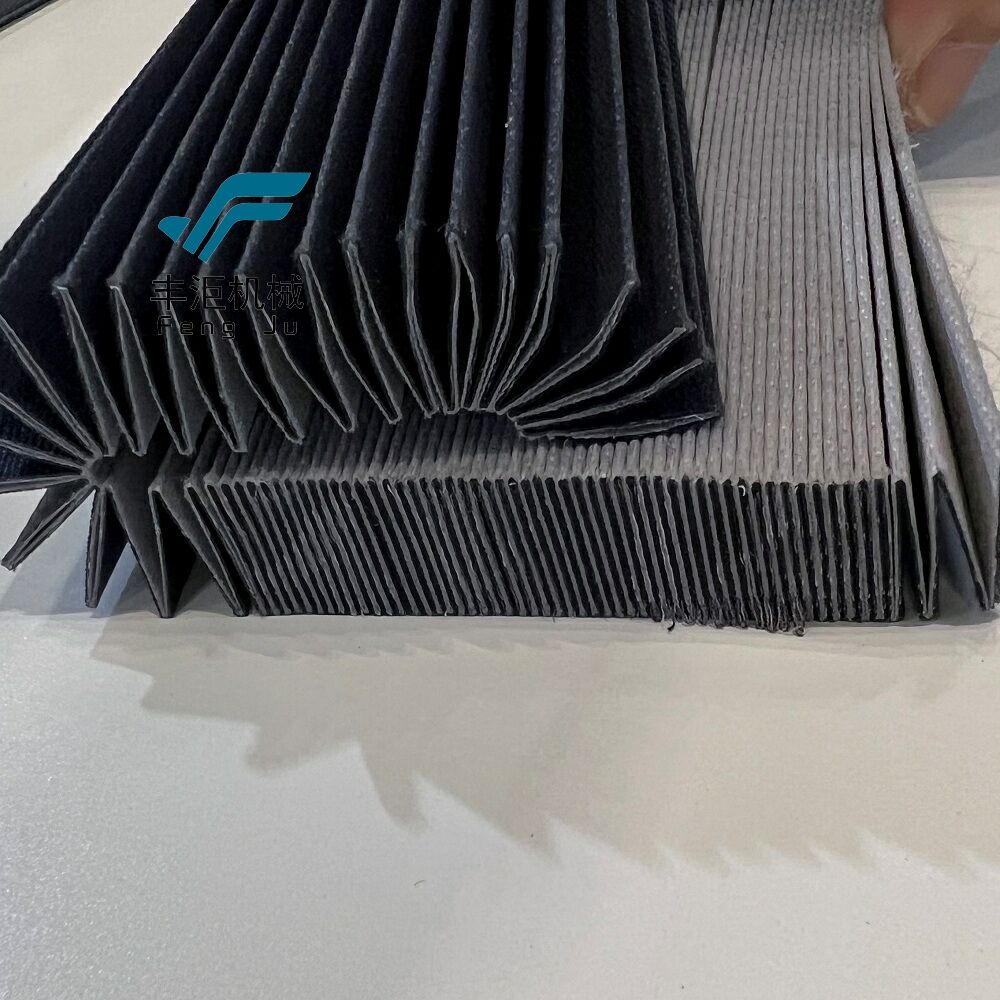

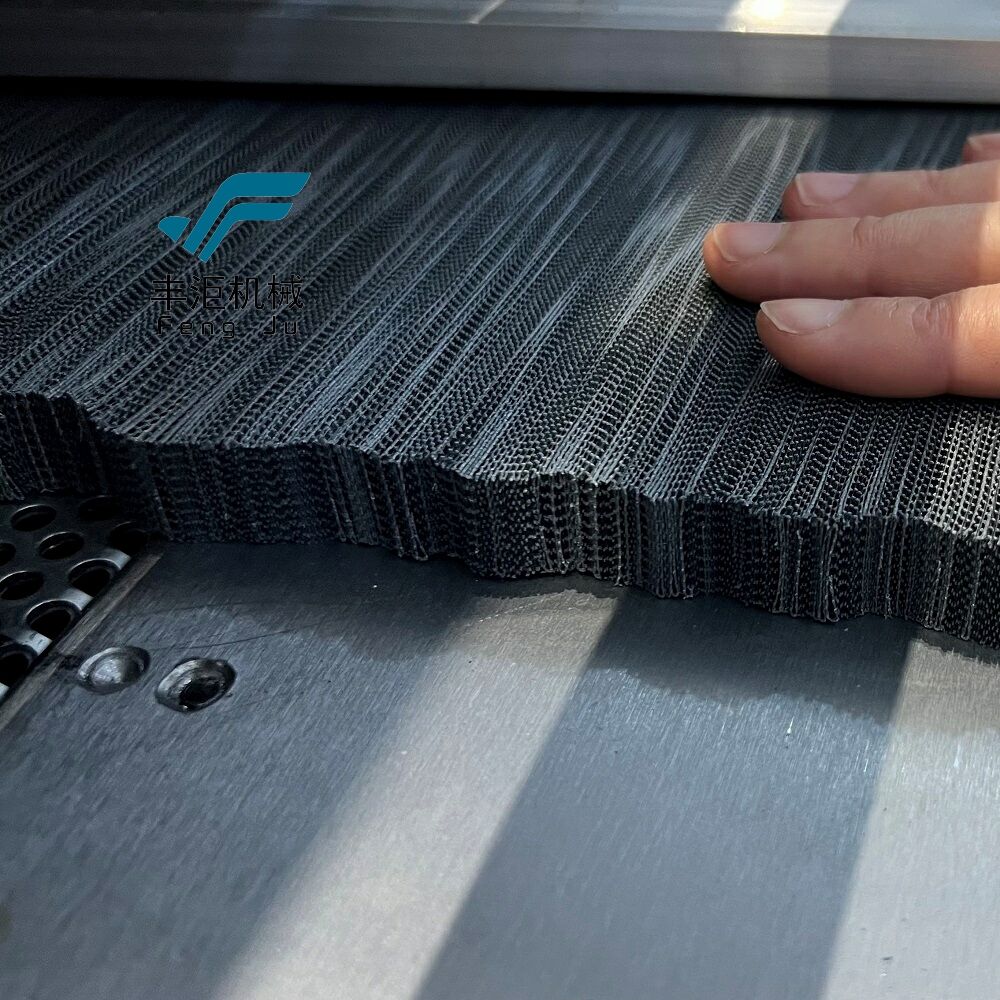

Máy gấp ly servo cho rèm đại diện cho bước đột phá trong công nghệ xử lý dệt tự động, mang lại khả năng kiểm soát chính xác và hiệu quả khi tạo các thiết kế rèm xếp ly. Thiết bị tiên tiến này sử dụng công nghệ động cơ servo để đảm bảo các mẫu ly chính xác và đồng đều trên nhiều loại vải khác nhau. Hệ thống điều khiển tinh vi của máy cho phép điều chỉnh chính xác độ sâu, khoảng cách và sự lặp lại của nếp ly, giúp các nhà sản xuất đạt được kết quả đồng nhất trong các dây chuyền sản xuất quy mô lớn. Hệ thống tích hợp nhiều trạm xử lý, bao gồm cấp vải, tạo ly và cơ chế định hình nhiệt, tất cả được đồng bộ thông qua giao diện kỹ thuật số trực quan. Với khả năng xử lý các độ rộng và độ dày vải khác nhau, máy có thể gia công các vật liệu từ loại vải mỏng nhẹ đến các loại rèm dày nặng. Hệ thống cấp vải tự động đảm bảo dòng vải chuyển động trơn tru, trong khi cơ chế gấp ly điều khiển bằng servo duy trì áp lực và độ chính xác nếp gấp ổn định. Các hệ thống điều khiển nhiệt độ được tích hợp vào máy đảm bảo quá trình định hình nhiệt các nếp ly phù hợp, tạo ra các nếp gấp bền chắc, rõ nét và giữ nguyên hình dạng theo thời gian. Thiết kế mô-đun của máy thuận tiện cho việc bảo trì dễ dàng và thay đổi mẫu mã nhanh chóng, làm cho nó phù hợp với cả các cơ sở sản xuất quy mô lớn lẫn các hoạt động sản xuất rèm theo yêu cầu quy mô nhỏ hơn.