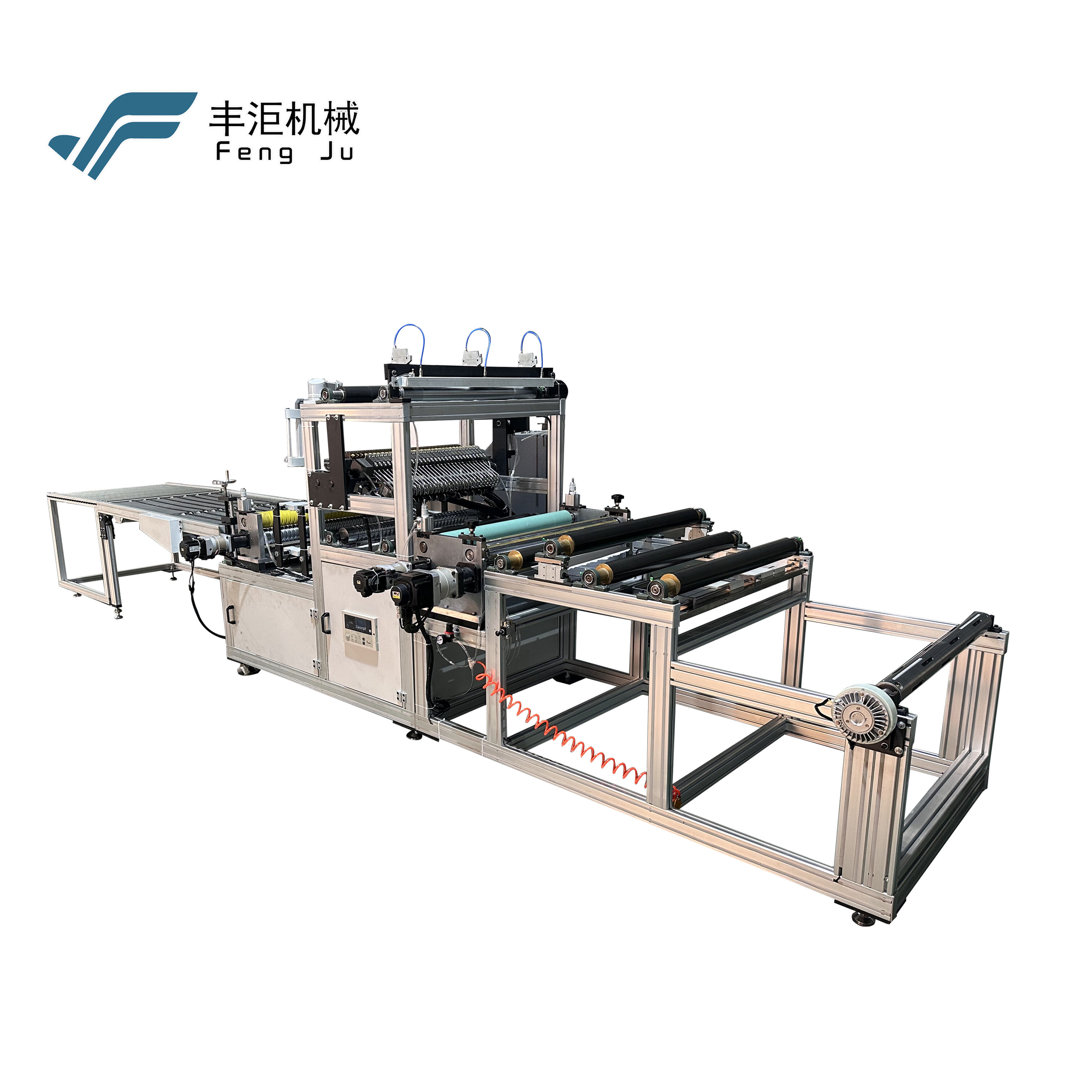

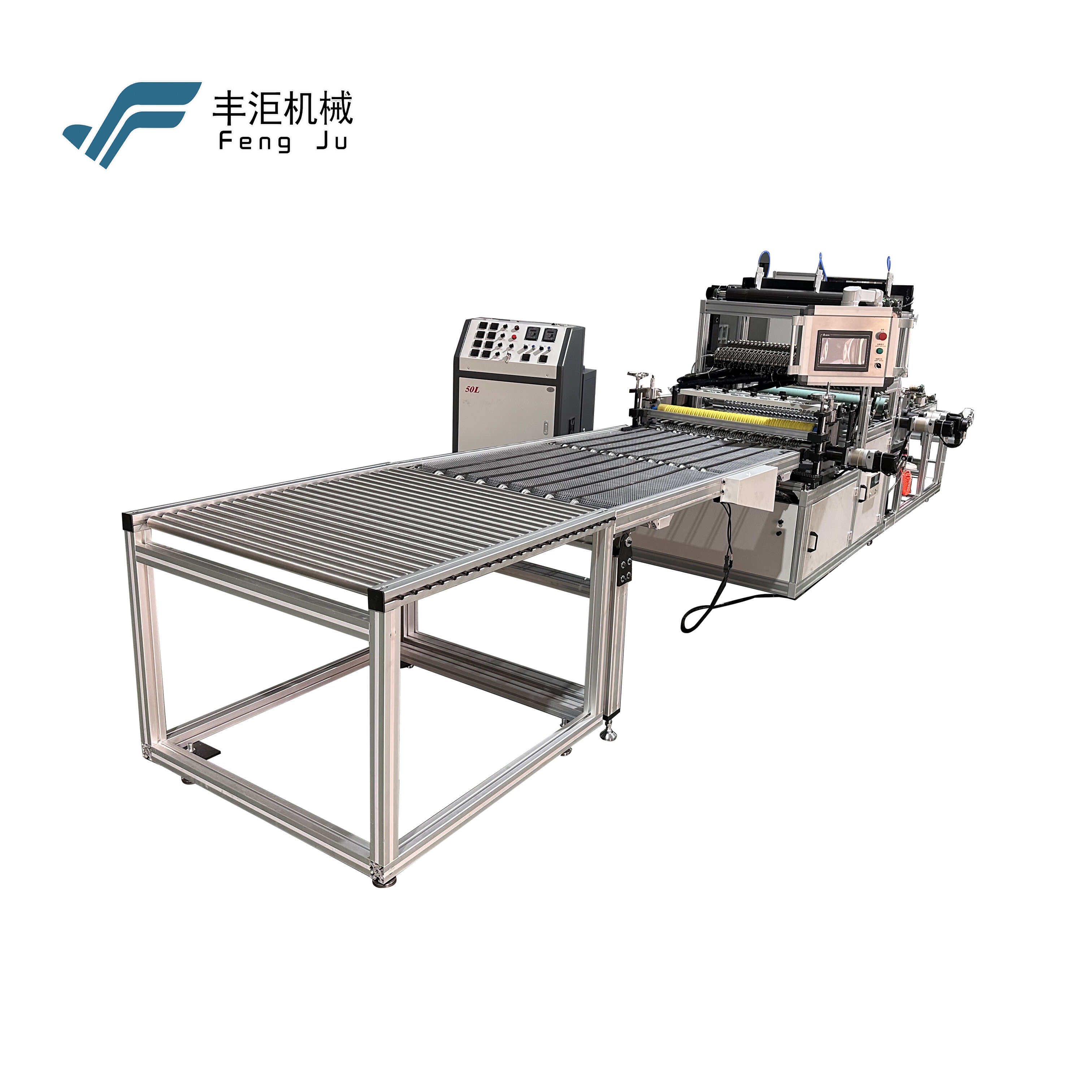

qog'oz filtri parraklarini yig'ish

Qog'oz filtrni bukchalamoq — bu tekis filtr materialini bukchali konfiguratsiyaga aylantiradigan murakkab ishlab chiqarish jarayoni bo'lib, filtr uchun mavjud sirt maydonini sezilarli darajada oshiradi va bir vaqtda ixcham o'lcham saqlanadi. Ushbu muhandislik g'ururi filtr qog'ozini bir xil garmoniya shaklidagi namoylar hosil qilish uchun aniq buklashni o'z ichiga oladi, bu esa parallel ko'plab bukchalarni yaratib, filtrlovchi sig'imni maksimal darajada oshiradi. Jarayon bukcha balandligi, chuqurligi va oraliqlarini optimal ishlashni ta'minlash uchun ehtimol boshqaradigan ilg'or bukchalash uskunalaridan foydalanadi. Har bir bukcha iloji boricha havo yoki suyuqlik oqimini saqlab turuvchi zaralarni ushlab qolish uchun mo'ljallangan. Texnologiya standart, chuqur va mayda bukchalar kabi turli xil bukcha oraliqlari usullarini o'z ichiga oladi, ular har biri maxsus filtratsiya talablari uchun xizmat qiladi. Bu bukchalangan filtrlar avtomobil havo filtrlari va HVAC tizimlaridan tortib, sanoat havosi tozalash hamda suyuqlik filtrlash jarayonlarigacha bo'lgan turli sohalarda keng qo'llaniladi. Bukchalash jarayoniga shuningdek, issiq-suyuq kleyni qo'llash va mexanik barqarorlashtirish kabi usullar orqali filtrning barqarorligi va chidamliligini oshirish maqsadida maxsus ishlov berish ham kiradi. Zamonaviy qog'oz filtrlarni bukchalash avtomatlashtirilgan sifat nazorati tizimlarini o'z ichiga oladi, bu esa doimiy bukcha geometriyasi va umumiy filtr ishlashini ta'minlaydi va zamonaviy filtratsiya echimlarining asosiy komponenti sifatida xizmat qiladi.